Elastic film variable-capacitance type platelet micro-force sensor based on micro-nano technology

A micro force sensor and variable capacitance technology, applied in the field of medical devices, can solve the problems of limited application, low measurement accuracy, and inability to observe the mechanical interaction of platelets in real time, and achieve the effect of quantitative and rapid measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Below in conjunction with embodiment, the present invention will be further described.

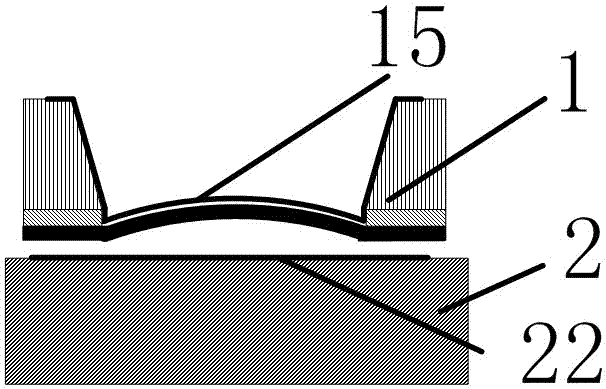

[0049] see figure 1 , a platelet micro force sensor based on micro-nano technology elastic thin film variable capacitance type is a parallel plate variable capacitor, including an anode plate 1 and a cathode plate 2 parallel to each other, the anode plate 1 is located at the top, and the cathode plate 2 is located at the bottom, and The anode working surface of the anode plate 1 corresponds to the anode working surface of the cathode plate 2, and the distance between the anode working surface and the cathode working surface is 500 microns.

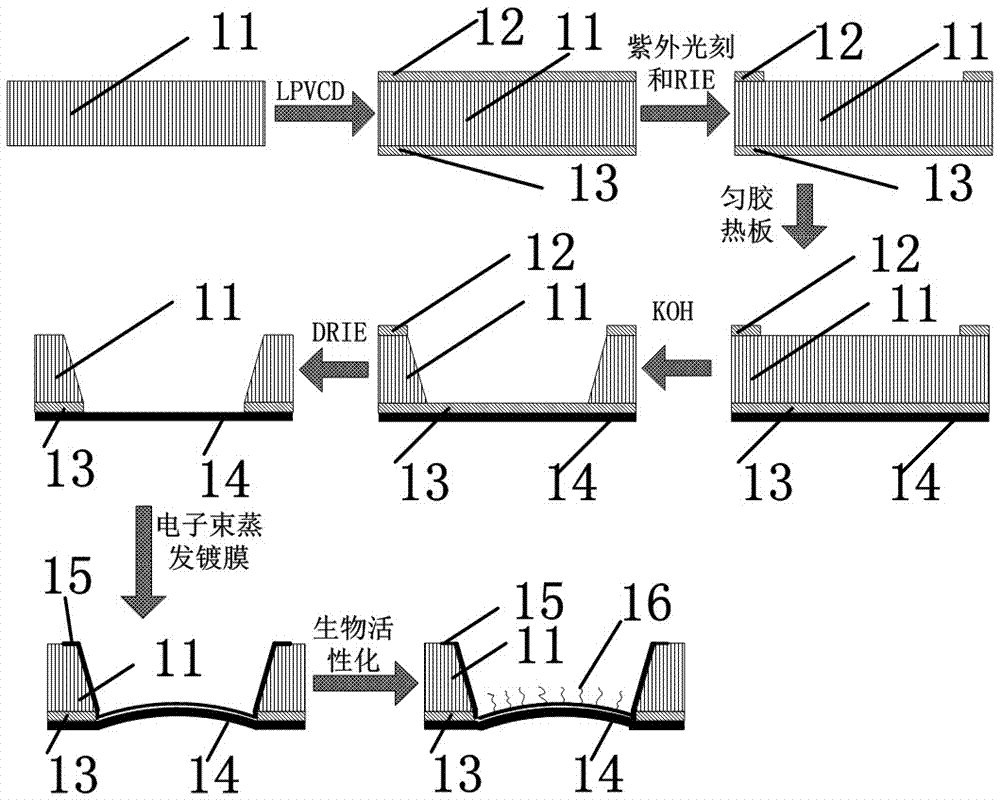

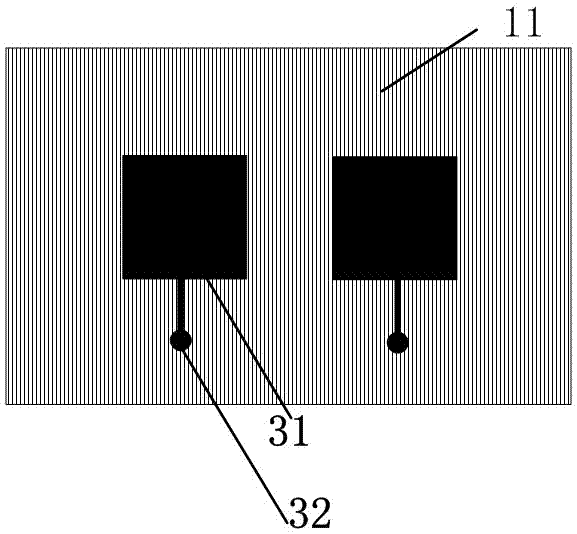

[0050] see figure 1 and image 3 The anode plate 1 includes a plate-shaped anode body 11, the anode body 11 is provided with an anode hole, and the diameter of the anode hole is 250 microns. The hole bottom and the hole wall of the anode hole are provided with an anode material area 15 composed of an anode material; the anode material area ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com