Hook-free fastening tape and manufacturing method thereof

A manufacturing method and technology of hook and loop fasteners, which can be applied to fasteners, clothing, applications, etc., can solve the problems of easy damage of the pile surface and the reduction of the fastening effect, and achieve the effects of small peeling force and shearing force and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

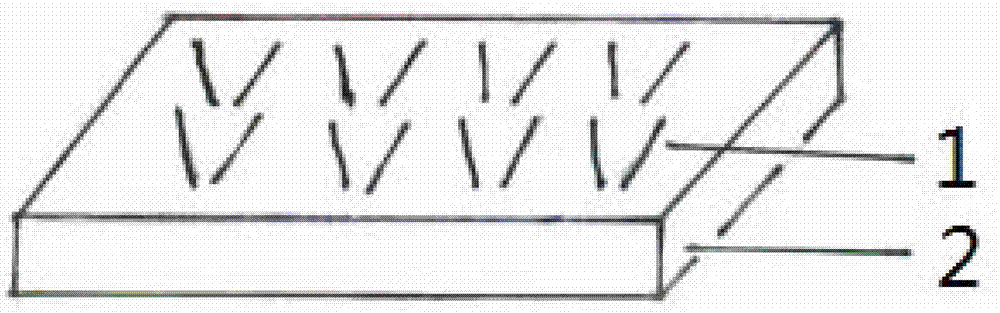

[0022] figure 1 Shown is the fastened part of the hookless hook-and-loop fastener of the present invention, the surface of the texture 2 of the hook-and-loop fastener is evenly distributed with terry loop dry 1, and the terry loop dry 1 adopts the structure of the loop terry. It is made after the arc is cut off. The surface of the hookless hook-and-loop fastener is a plush fabric, and the hooking force is formed by the entanglement of the plush fabric and the terry loop stem 1, so that the hook-and-loop fastener and the fastened belt are glued to each other.

[0023] When the hookless Velcro is being weaved, the warp yarns are arranged in the following manner: 1 polyester loop yarn and 4 polyester ground warps. The fineness of polyester terry yarn is 0.05mm, the fineness of polyester ground warp is 0.10mm, the fineness of polyester weft yarn is 0.10mm, the height of polyester terry yarn is 1.6mm, and all raw materials are polyester monofilament. At the same time, the ultravi...

Embodiment 2

[0027] When the hookless Velcro is being weaved, the warp yarns are arranged in the following manner: 1 polyester loop yarn and 4 polyester ground warps. The fineness of polyester terry yarn is 0.06mm, the fineness of polyester ground warp is 0.13mm, the fineness of polyester weft yarn is 0.13mm, the height of polyester terry yarn is 1.8mm, and all raw materials are polyester monofilament. At the same time, the ultraviolet lamp tube does not need to heat the terry, and does not need to eliminate the internal stress of the terry.

[0028] When the hook-free adhesive tape was prepared with a coating adhesive coating, the coating adhesive formula was: resin: methyl ethyl ketone: the weight ratio of the bonding agent was 1: 0.9: 0.7, and the amount of glue on the adhesive tape was 130g / m 2 , Dry the glued Velcro at 100°C. The resin is CX-6950D resin produced by Coating Fine Chemicals (Kunshan) Co., Ltd., and the bonding agent is CA-861 bonding agent produced by Coating Fine Che...

Embodiment 3

[0031] When the hookless Velcro is being weaved, the warp yarns are arranged in the following manner: 1 polyester loop yarn and 4 polyester ground warps. The fineness of polyester terry yarn is 0.08mm, the fineness of polyester ground warp is 0.16mm, the fineness of polyester weft yarn is 0.16mm, the height of polyester terry yarn is 2.0mm, and all raw materials are polyester monofilament. At the same time, the ultraviolet lamp tube does not need to heat the terry, and does not need to eliminate the internal stress of the terry.

[0032] When preparing the coating adhesive coating for the hook-free adhesive tape, the coating adhesive formula is: resin: methyl ethyl ketone: the weight ratio of the bonding agent adopts 1: 1: 0.8, and the consumption of glue on the adhesive tape is 150g / m 2 , Dry the glued Velcro at 105°C. The resin is CX-6950D resin produced by Coating Fine Chemicals (Kunshan) Co., Ltd., and the bonding agent is CA-861 bonding agent produced by Coating Fine C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com