Vacuum compression bag and manufacturing method thereof

A technology of vacuum compression bag and production method, applied in the field of packaging bags, can solve problems such as poor adhesion, high cost, fatigue damage, etc., and achieve the effects of avoiding the influence of strength, improving weather resistance, and excellent flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

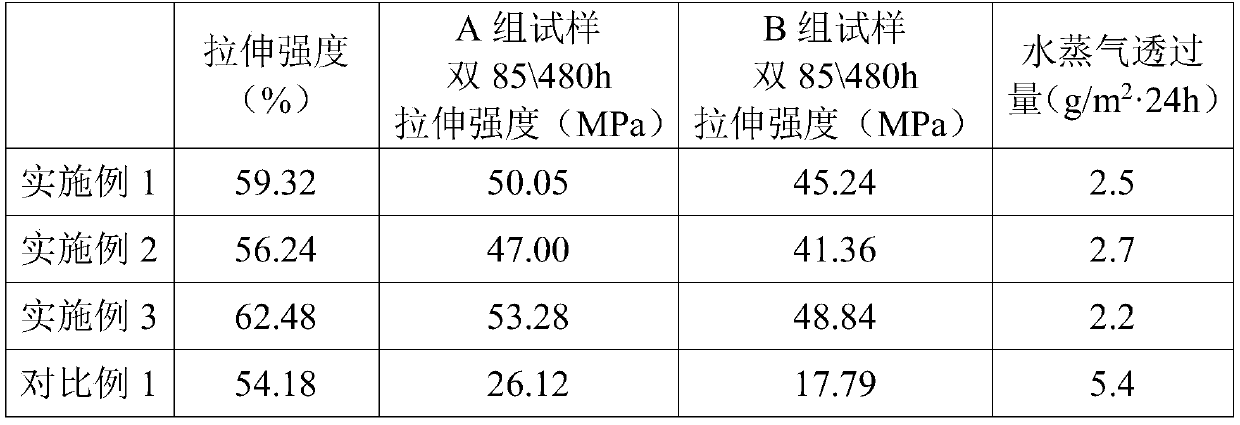

Embodiment 1

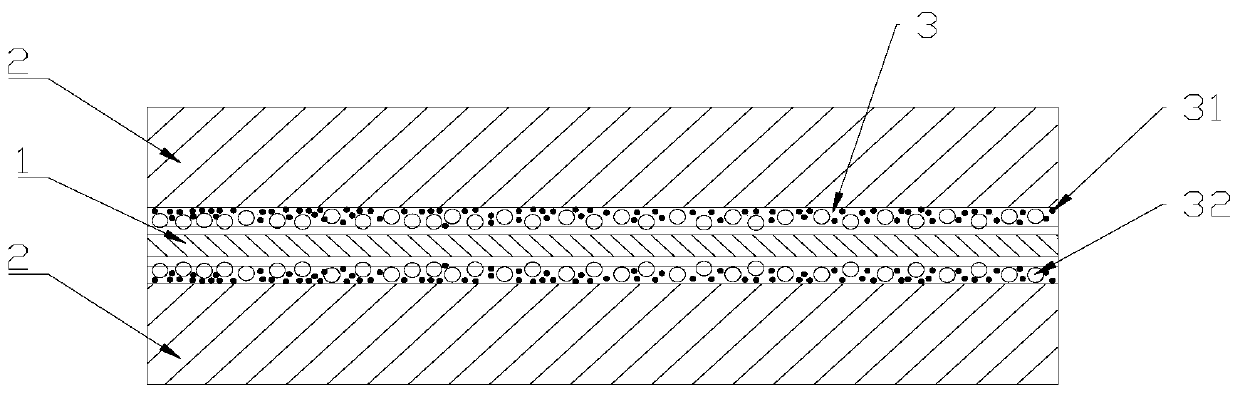

[0034] A vacuum compression bag, comprising a PE film layer (LDPE, 30 μm, the raw material is taken from Yangzi BASF 1810D) and a PET film layer (20 μm, the raw material is taken from China Yizheng Chemical Fiber, and the intrinsic viscosity is 0.68dL / g). The film layer is arranged on both sides of the PE film layer, and a 10 μm thick weather-resistant coating is provided on the side of the PET film layer adjacent to the PE film layer;

[0035] Wherein, the weather-resistant coating contains polyurethane resin glue (viscosity of 300mpa·S), polyphosphazene microspheres (diameter of 10 μm), glass powder (particle size of 5 μm) and ethyl acetate;

[0036] With respect to 100 parts by weight of the polyurethane resin glue, the content of the polyphosphazene microspheres is 18 parts by weight, the content of the glass powder is 30 parts by weight, and the content of the ethyl acetate is 200 parts by weight.

[0037] The manufacture method of above-mentioned vacuum compression bag com...

Embodiment 2

[0040] This embodiment has the same structure as the vacuum compression bag in Example 1, and the preparation method is the same. The difference is that in the weather-resistant coating, relative to 100 parts by weight of polyurethane resin glue, the polyphosphazene microspheres The content is 10 parts by weight, the content of the glass powder is 20 parts by weight, and the content of the ethyl acetate is 150 parts by weight; the rest remain unchanged.

Embodiment 3

[0042] This embodiment has the same structure as the vacuum compression bag in Example 1, and the preparation method is the same. The difference is that in the weather-resistant coating, relative to 100 parts by weight of polyurethane resin glue, the polyphosphazene microspheres The content is 25 parts by weight, the content of the glass powder is 40 parts by weight, and the content of the ethyl acetate is 200 parts by weight; the rest remain unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com