Antibacterial agent

A technology of antibacterial agent and concentration, applied in the direction of antifungal agent, local antibacterial agent, antibacterial drug, etc., can solve the problem of ineffective sterilization effect, achieve the effect of increased antibacterial rate and good antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] An antibacterial agent, comprising 3 parts of silver nitrate solution with a mass fraction of 5%, 6 parts of cationic antibacterial agent, 2 parts of epicatechin gallate, 15 parts of ethanol, 4 parts of peppermint, and 70 parts of water;

[0019] The preparation method of the antibacterial agent: Dissolve glycerin, epicatechin gallate and peppermint in ethanol at 50°C to make an organic phase. Add cationic antibacterial agent to the organic phase and keep stirring to make it fully The mixed solution is obtained after mixing, and then a silver nitrate solution with a mass fraction of 5% is added, and water is added for mixing, and the liquid is obtained after thorough mixing.

Embodiment 2

[0021] An antibacterial agent, comprising 4 parts of silver nitrate solution with a mass fraction of 5%, 8 parts of cationic antibacterial agent, 4 parts of epicatechin gallate, 17 parts of ethanol, 5 parts of peppermint, and 57 parts of water;

[0022] The preparation method of the antibacterial agent: Dissolve glycerin, epicatechin gallate and peppermint in ethanol at 55°C to prepare an organic phase. Add the cationic antibacterial agent to the organic phase and keep stirring to make it fully The mixed solution is obtained after mixing, and then a silver nitrate solution with a mass fraction of 5% is added, and water is added for mixing, and the liquid is obtained after thorough mixing.

Embodiment 3

[0024] An antibacterial agent, comprising 5 parts of silver nitrate solution with a mass fraction of 5%, 10 parts of cationic antibacterial agent, 5 parts of epicatechin gallate, 20 parts of ethanol, 6 parts of peppermint, and 54 parts of water;

[0025] Preparation method of antibacterial agent: Dissolve glycerin, epicatechin gallate, and peppermint in ethanol at 60°C to form an organic phase. Add cationic antibacterial agent to the organic phase and keep stirring to make it fully The mixed solution is obtained after mixing, and then a silver nitrate solution with a mass fraction of 5% is added, and water is added for mixing, and the liquid is obtained after thorough mixing.

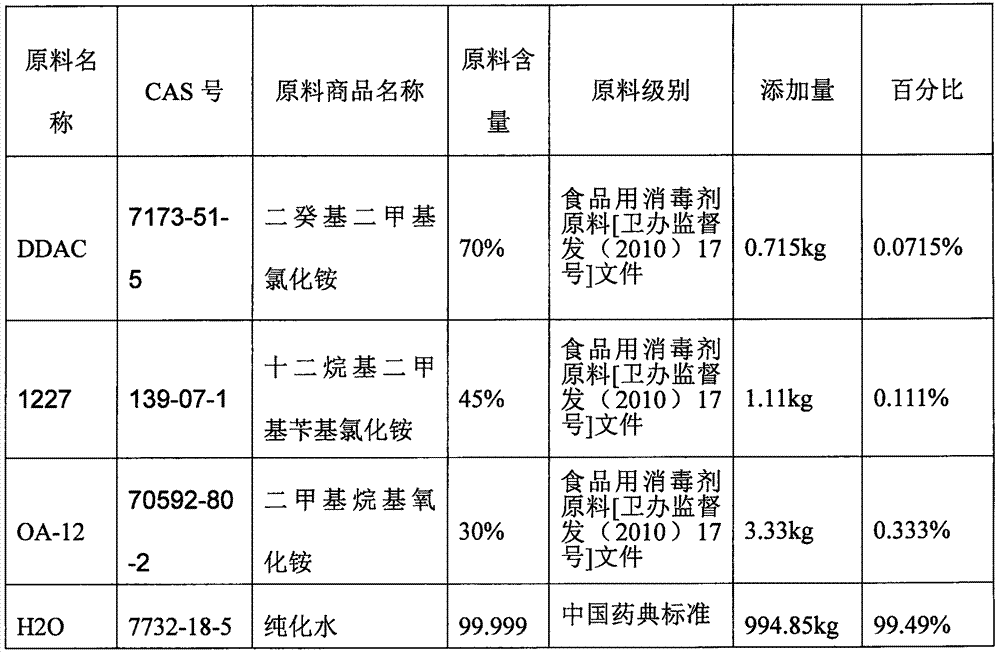

[0026] Table 1 `Cation antibacterial agent formula

[0027]

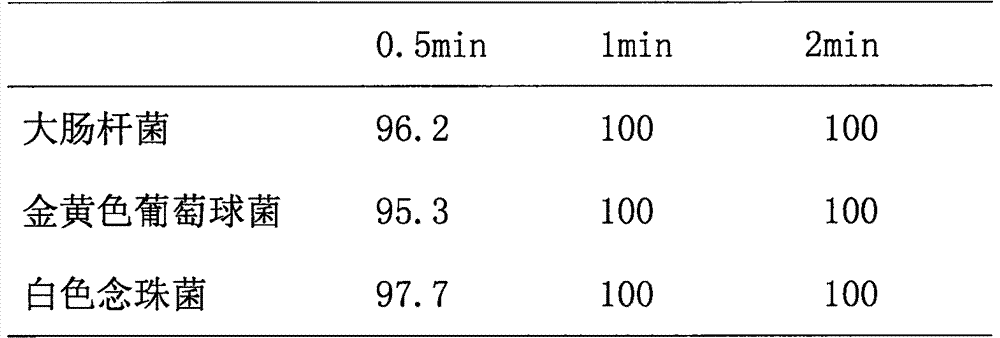

[0028] The preparation method of the antibacterial agent: Dissolve glycerin, epicatechin gallate and peppermint in ethanol at 60°C, then add glycerin and mix well to make an organic phase. Add the cationic antibacterial agent to the organic phase. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com