Lacquer face polishing device

A polishing device and paint surface technology, applied in the field of automobile polishing, can solve the problems of slow polishing processing speed, high risk, delayed delivery time, etc., and achieve the effects of fast polishing processing speed, shortening delivery time, and increasing cutting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

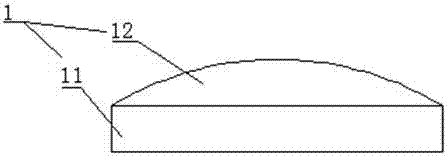

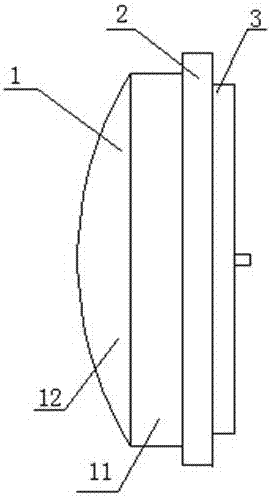

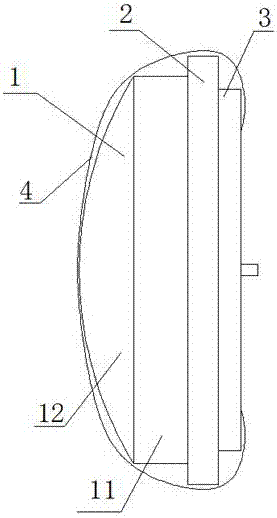

[0027] Embodiment 1 A kind of paint surface polishing device

[0028] Such as Figure 1-3 As shown, the present invention provides a paint surface polishing device, including a polishing cotton 1, the polishing cotton 1 includes a cylindrical base 11 and a spherical convex portion 12, one end of the cylindrical base 11 is connected to the spherical convex portion 12, the The cylindrical base 11 and the spherical convex portion 12 are integrally formed. Using the above-mentioned structure for polishing treatment, the speed is fast, the risk is extremely low, and the delivery time is greatly shortened. Taking a car door as an example, it takes about 60 minutes to polish using the existing polishing technology, but it only takes about 10 minutes to polish using the polishing wheel of the present invention.

[0029] The outer diameter of the cylindrical base 11 is the same as the outer diameter of the spherical protrusion 12 .

[0030] The height of the cylindrical base 11 is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com