Anaerobic biological decalcification system and method

A technology of anaerobic biology and anaerobic sludge, which is applied in anaerobic biological decalcification system and decalcification field, can solve the problems of high energy consumption, high cost of decalcification treatment, complex structure of sewage decalcification device, etc., and achieve system investment Large, low-cost biological decalcification, the effect of improving removal efficiency and system stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

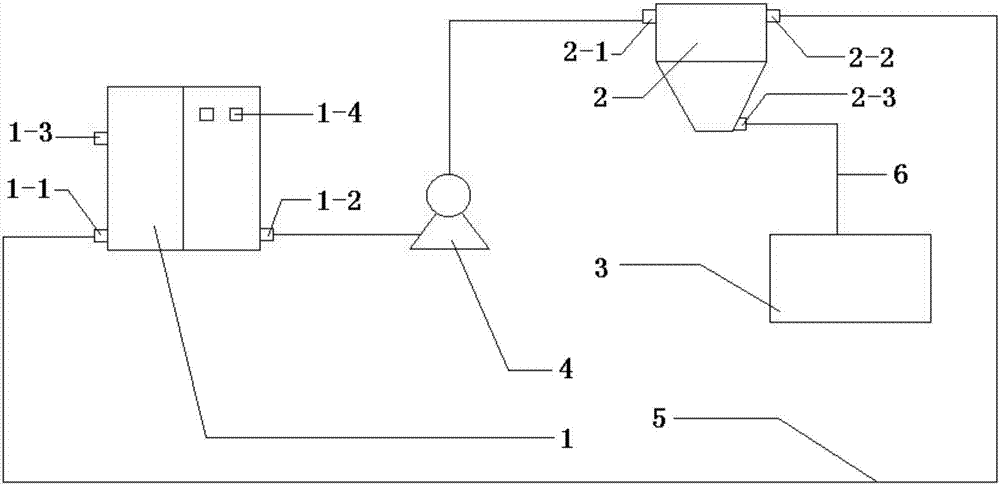

[0025] An anaerobic biological decalcification system, comprising an anaerobic reactor 1, a calcium salt separation tank 2, a calcium salt storage tank 3 and a pump 4, the anaerobic reactor 1 is provided with a sludge feed port 1-1, Sludge discharge port 1-2, sewage water inlet 1-3 and sewage water outlet 1-4, described calcium salt separation tank 2 is provided with calcium salt separation tank feed port 2-1, calcium salt separation tank sludge Discharge port 2-2 and calcium salt separation tank calcium salt discharge port 2-3, described sludge discharge port 1-2 is connected with calcium salt separation tank feed port 2-1 by pump 4, described The sludge discharge port 2-2 of the calcium salt separation tank is connected to the sludge feed port 1-1 through the sludge return pipe 5, and the calcium salt discharge port 2-3 of the calcium salt separation tank is connected to the calcium salt storage tank 3 connect.

[0026] In this embodiment, the calcium salt separation tank 2...

Embodiment 2

[0028] As described in Example 1, the difference is:

[0029] The calcium salt separation tank 2 is a vertical separation tank, and the height of the calcium salt separation tank 2 is 7m.

Embodiment 3

[0031] Utilize the system described in embodiment 1 to carry out the method for anaerobic biological decalcification, comprise steps as follows:

[0032] Open the anaerobic reactor 1, the sewage enters the anaerobic reactor 1 through the sewage water inlet 1-3, and controls the pH value of the anaerobic reactor 1 at 6.5-9 by adding sodium hydroxide or sodium bicarbonate when necessary, and the sewage Calcium ions in the anaerobic reactor are precipitated in the form of calcium salt and mixed in the anaerobic sludge in the anaerobic reactor 1, and then the anaerobic sludge in the anaerobic reactor 1 is passed through the pump 4 from the sludge outlet 1-2 Enter the calcium salt separation tank 2 through the feed port 2-1 of the calcium salt separation tank for precipitation. The calcium salt is heavier than the anaerobic sludge and will automatically precipitate to the bottom of the calcium salt separation tank 2. The precipitated calcium salt is separated from the calcium salt. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com