Self-stirring purification tank convenient for assembling and disassembling

A convenient assembly and self-stirring technology, which is applied in the field of septic tanks, can solve the problems that the pain point of dispersing sewage has not been effectively solved, the technical advantages of septic tanks cannot be effectively utilized, and the application of septic tank technology is restricted, so as to achieve high sewage treatment efficiency and avoid stirring Effect with low efficiency and significant beneficial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

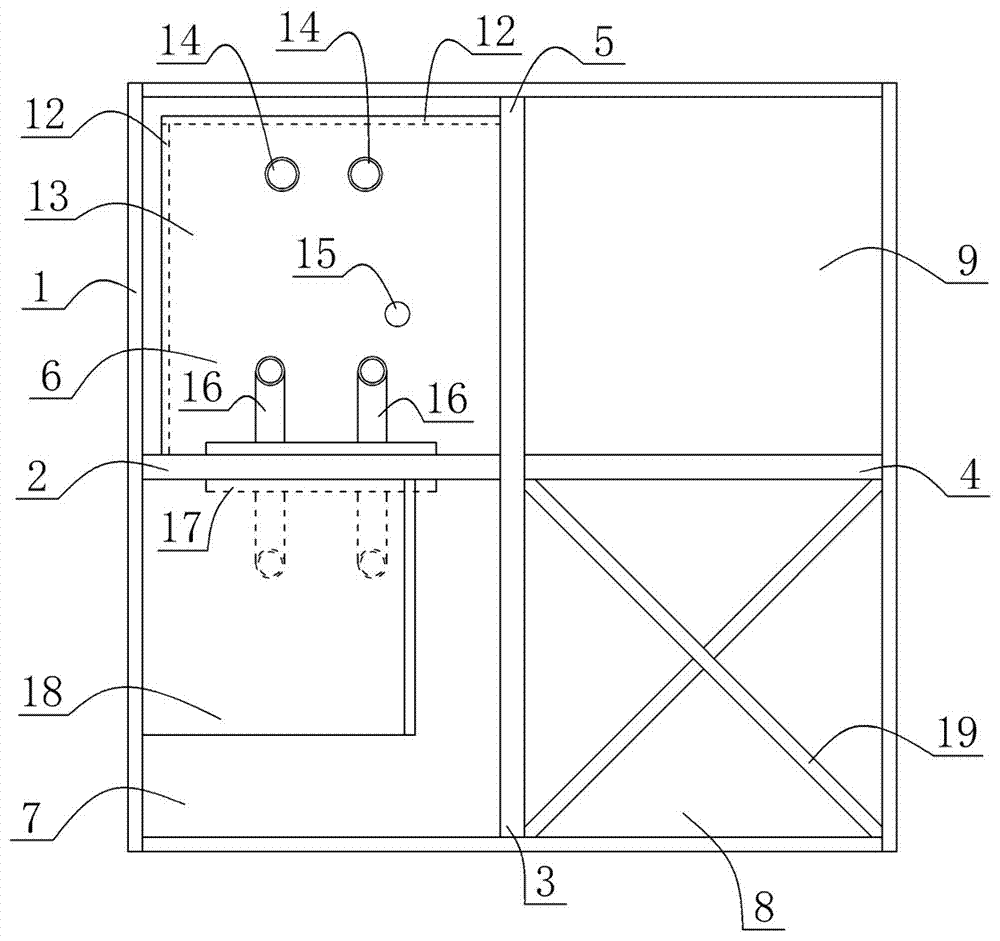

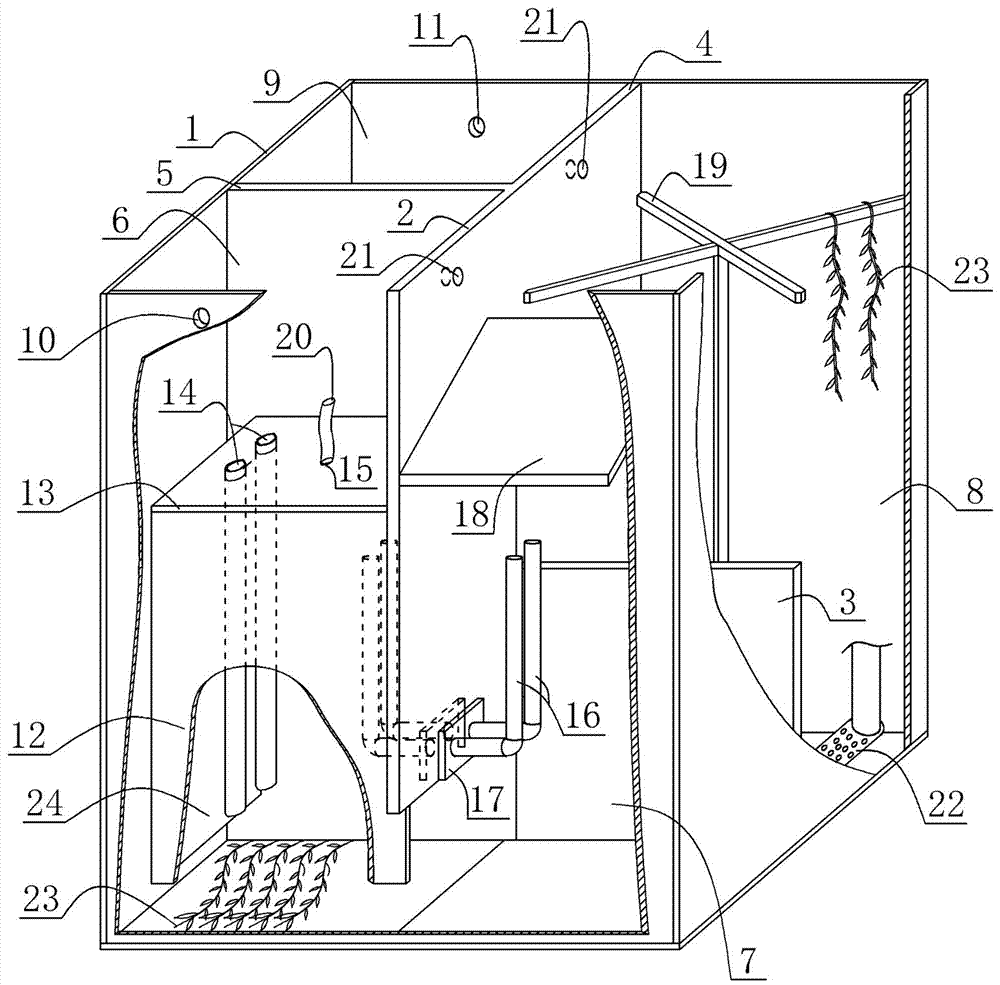

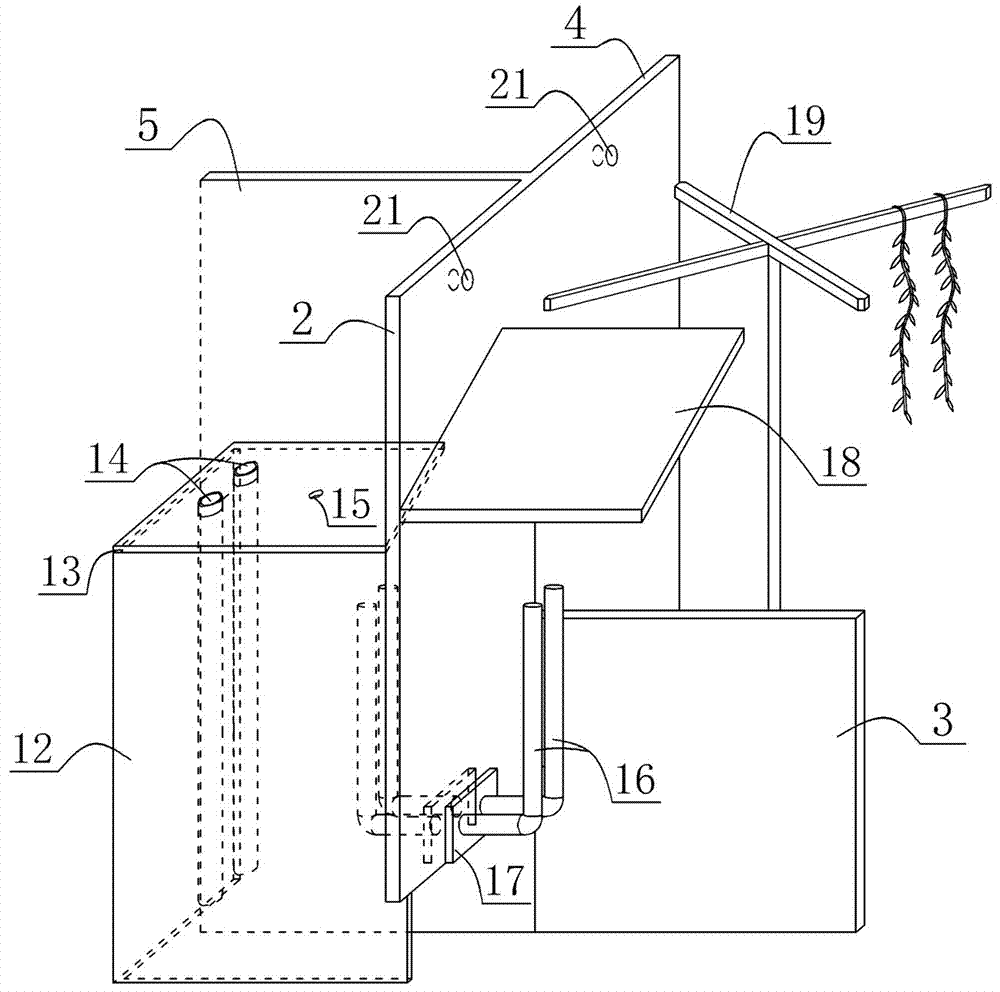

[0022] Such as figure 1 and figure 2 As shown, the top view and perspective view of the self-stirring purification tank of the present invention are provided respectively. The self-stirring purification tank shown is composed of a housing 1, a first partition 2, a second partition 3, a third partition 4, a second partition Four partitions 5, vertical partitions 12, horizontal partitions 13, conduits 14, U-shaped pipes 16, and inclined partitions 18 are formed. The inside of the housing 1 shown is a cavity, and the four partitions (the first and the second 2. The third and fourth partitions) are sequentially arranged in the inner cavity of the housing 1, and divide the inner cavity of the housing 1 into the first grid slot 6, the second grid slot 7, and the third grid slot 8 and fourth slot 9. The bottoms of the first dividing plate 2 and the third d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com