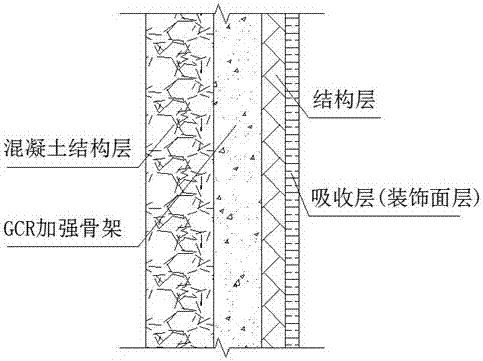

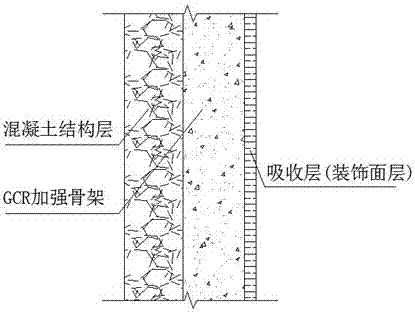

GRC building member with functions of air purification and self-cleaning, and manufacturing method thereof

A technology for building components and air purification, which is applied in the field of building concrete materials, and can solve problems such as unsustainability and increased maintenance costs for building exterior walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

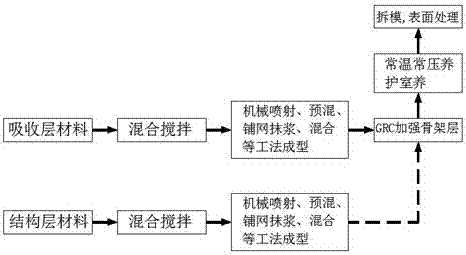

Method used

Image

Examples

Embodiment 1

[0058] The GRC building components produced by the proportioning of Table 1, wherein kaolin powder (%) refers to kaolin powder is the wt% of cement amount, TiO2 (%) refers to titanium dioxide as the wt% of cement amount. Tensile Strength, Flexural Strength and NO x Methods for determining the rate of reduction are well known in the art. Self-cleaning ability is the time to test the disappearance of pollutants on the surface of GRC.

[0059] From the ratio listed in Table 1 and the characteristics of the produced GRC building components, it can be seen that the ability of GRC to reduce NOx increases with the increase of the content of titanium dioxide while the structural layer remains unchanged. At the same time the time required to remove red pigment from GRC building components is reduced. Under the same content of titanium dioxide, the fineness of quartz sand has little effect on the reduction rate of NOx and the time required to remove red pigment.

[0060] Table 1

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com