Waster rubber powder composite modified asphalt and preparation method thereof

A technology of composite modified asphalt and modified asphalt, which is applied in the direction of building components, building insulation materials, buildings, etc., can solve the problems of low mechanical properties, poor compatibility, poor stability, etc., to improve dispersion performance and wear resistance , the effect of preventing self-vulcanization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

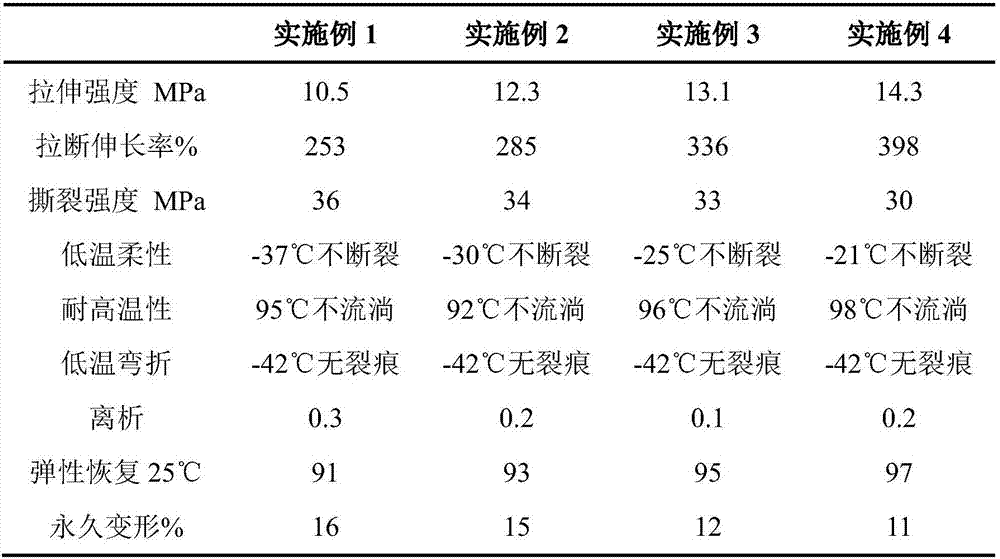

Examples

Embodiment Construction

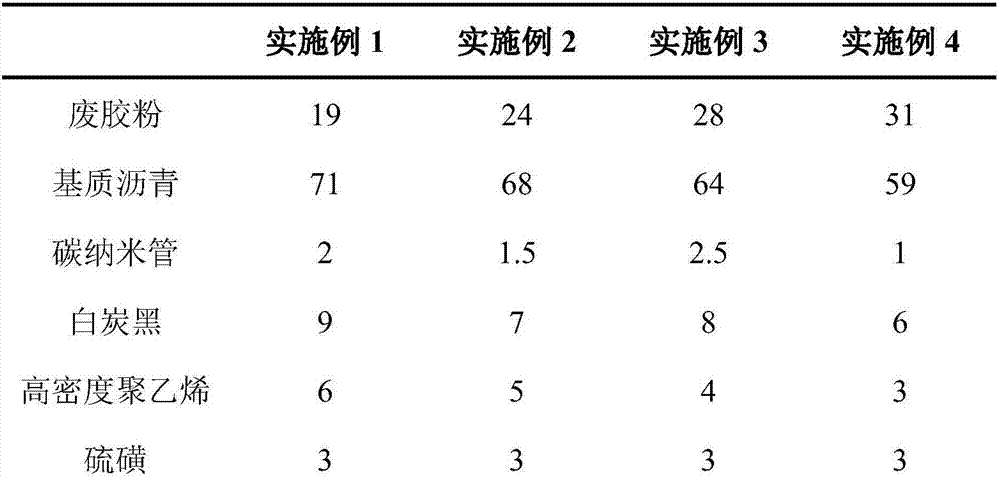

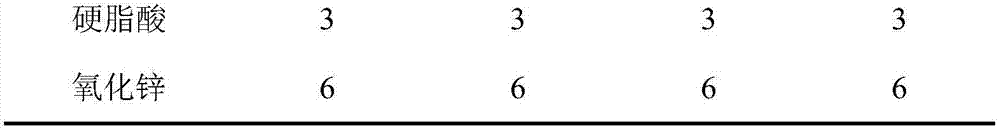

[0028] A waste rubber powder composite modified asphalt, the raw materials are composed of the following materials according to the weight ratio: waste rubber powder 18-32%, matrix asphalt 58-72%, carbon nanotubes 1-3%, white carbon black 5-10%, High-density polyethylene 3-7%, sulfur 2-4%, stearic acid 2-7%, zinc oxide 5-8%.

[0029] The particle size of waste rubber powder is 10-20 mesh, and the base asphalt is 90# asphalt.

[0030] A preparation method of waste rubber powder composite modified asphalt, comprising the following steps:

[0031] (1) The waste rubber powder recovered from waste tires and base asphalt are preliminarily mixed and preheated by a feeding device, and then put into a double-rotor continuous mixer equipped with a microwave generating device and subjected to high-speed shearing, stretching and microwave After desulfurization modified asphalt works together, waste rubber powder mixed modified asphalt is obtained;

[0032] (2) carbon nanotubes and white...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com