Biological modifying and flooding agent capable of resisting against high temperature and high salt for oil field exploitation

A medium-high-temperature technology for regulating and displacing agents, which is applied in the fields of mining fluids, drilling compositions, earthwork drilling, etc., can solve the problems of reducing interfacial tension, unstable performance, and inapplicability, so as to improve the residual resistance coefficient and improve the Effect of Drag Coefficient, High Sweep Coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

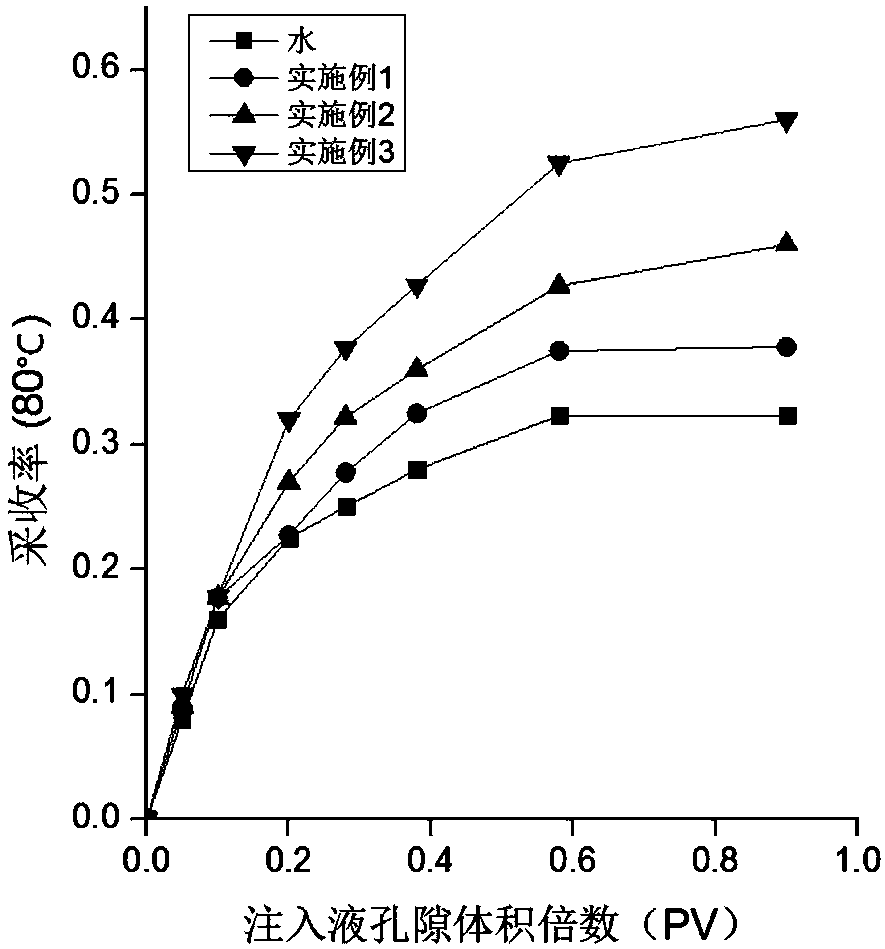

Embodiment 1

[0034] Example 1: Preparation of medium-high-temperature, high-salt bio-displacement agent for oilfield development

[0035] 1. Formulation:

[0036] Microbial polysaccharide 1%, surfactant 0.1%, bonding force promoter 0.05, and the balance is water. The above are all percentages by weight.

[0037] Among them, the microbial polysaccharide is welan gum, the surfactant is betaine, the bonding force promoter is curdlan gum, and modified starch in a mass ratio of 1:1.

[0038] 2. Preparation method:

[0039] (1) Dissolve the microbial polysaccharide (welan gum) with part of the water (1 / 3 of the water), pre-swell, the pre-swelling temperature is 25°C, and the pre-swelling time is 30min, to obtain the microbial polysaccharide solution;

[0040] (2) Add the surfactant (betaine) and the bonding force promoter into the remaining water, stir to dissolve; then add the microbial polysaccharide solution, and continue to stir for 1 hour to obtain the bio-displacement agent.

Embodiment 2

[0041] Example 2: Preparation of medium-high-temperature, high-salt bio-displacement agent for oilfield development

[0042] 1. Formulation:

[0043] 1.1% of microbial polysaccharide, 0.5% of surfactant, 2.5% of bonding force accelerator, and the balance is water.

[0044] Among them, the microbial polysaccharide is welan gum, the surfactant is rhamnolipid, the bonding force promoter is locust bean gum and curdlan gum, and they are mixed according to the mass ratio of 1:1.

[0045] The preparation method is the same as in Example 1.

Embodiment 3

[0046] Example 3: Preparation of medium-high-temperature, high-salt bio-displacement agent for oilfield development

[0047] 1. Formulation:

[0048] Microbial polysaccharide 1.0%, surfactant 0.6%, bonding force accelerator 5%, and the balance is water.

[0049] Among them, the microbial polysaccharide is welan gum, the surfactant is rhamnolipid, and the bonding force promoter is a mixture of sodium citrate and curdlan gum in a mass ratio of 1:3.

[0050] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com