ZnO quantum dot and anti-counterfeit ink and security file prepared by using ZnO quantum dot

The technology of anti-counterfeiting ink and quantum dots is applied in the field of anti-counterfeiting, which can solve the problems of impure chromaticity, reduce the difficulty of counterfeiting, unfavorable machine-readable identification, etc., and achieve the effects of simple preparation method, improved anti-counterfeiting performance, and no color appearance in appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Take 10g of zinc acetate and 1000ml of DMF solution, stir at 25°C for 10min to dissolve the zinc acetate, then increase the reaction temperature to 90°C and keep it for 5 hours to obtain white ZnO quantum dot precipitates. After centrifugation and drying at 50° C. for 2 hours, about 3 g of ZnO quantum dot white powder was obtained.

[0020] Take 3g of the above-mentioned quantum dot powder and 7g of offset printing base ink and mix to prepare an offset printing ink containing quantum dots.

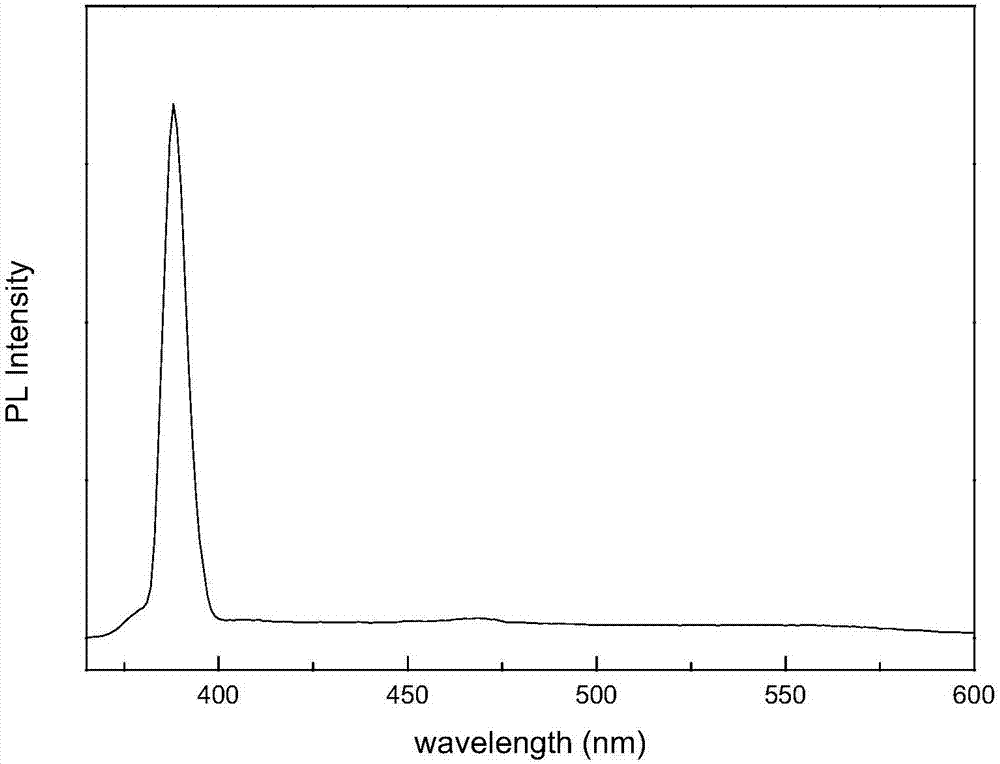

[0021] The above-mentioned offset printing ink is printed into a specific pattern to form a security document. This security document is colorless under natural light, and has no color in appearance under the excitation light of 325nm. The visible area forms a fluorescent emission peak with a half-peak width less than 50nm, which is different from any current fluorescent material, thereby forming an anti-counterfeiting effect.

Embodiment 2

[0023] Take 10g of zinc acetate and 900ml of DMF solution, stir at 30°C for 30min to dissolve the zinc acetate, then increase the reaction temperature to 95°C and keep it for 8 hours to obtain white ZnO quantum dot precipitates. After centrifugation and drying at 50° C. for 2 hours, about 3 g of ZnO quantum dot white powder was obtained.

[0024] Take 3g of the above-mentioned quantum dot powder and 7g of offset printing red fluorescent base ink and mix to prepare an offset printing ink containing quantum dots.

[0025] Print the above-mentioned offset printing ink into a specific pattern to form a security document. This security document is colorless under natural light. Under the excitation light of 325nm, it does not show red fluorescence in appearance. At the same time, a fluorescent emission peak with a half-peak width less than 50nm is formed in the ultraviolet invisible region around 380nm, which is different from any current fluorescent material, thus forming an anti-...

Embodiment 3

[0027] Take 20g of zinc acetate and 2200ml of DMF solution, stir at 35°C for 20min to dissolve the zinc acetate, then increase the reaction temperature to 105°C and keep it for 10 hours to obtain white ZnO quantum dot precipitates. After centrifugation and drying at 50° C. for 2 hours, about 6 g of ZnO quantum dot white powder was obtained.

[0028] Take 3g of the above-mentioned quantum dot powder and 7g of offset printing varnish or color paste to make offset printing ink containing quantum dots. figure 1 The fluorescent effect shown can be effectively distinguished from traditional fluorescent inks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com