A method for high-yield exopolysaccharide production by Lactobacillus plantarum

A technology of Lactobacillus plantarum and exopolysaccharide, which is applied in the field of high production of exopolysaccharide by Lactobacillus plantarum, can solve the problems of low yield, different EPS yield and performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Embodiment 1 Fermentation and extraction and purification of exopolysaccharide of Lactobacillus plantarum La-10

[0078] Lactobacillus plantarum La-10 was inoculated in the improved MRS liquid medium at an inoculum size of 4% volume fraction, and the fermentation temperature was 30°C, and it was cultured statically for 30 hours, wherein the sucrose content in the improved MRS liquid medium was 30g / L.

[0079] Table 2 The highest extraction amount of each single factor

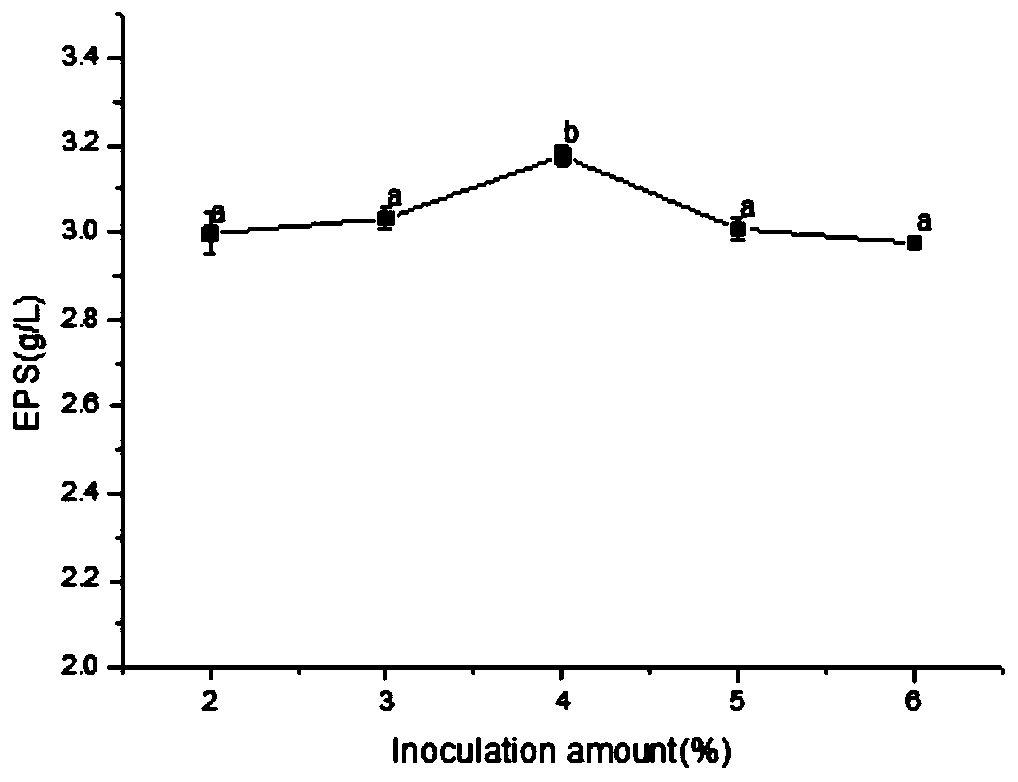

[0080] single factor EPS(g / L) Inoculation amount 3.1756±0.02 b

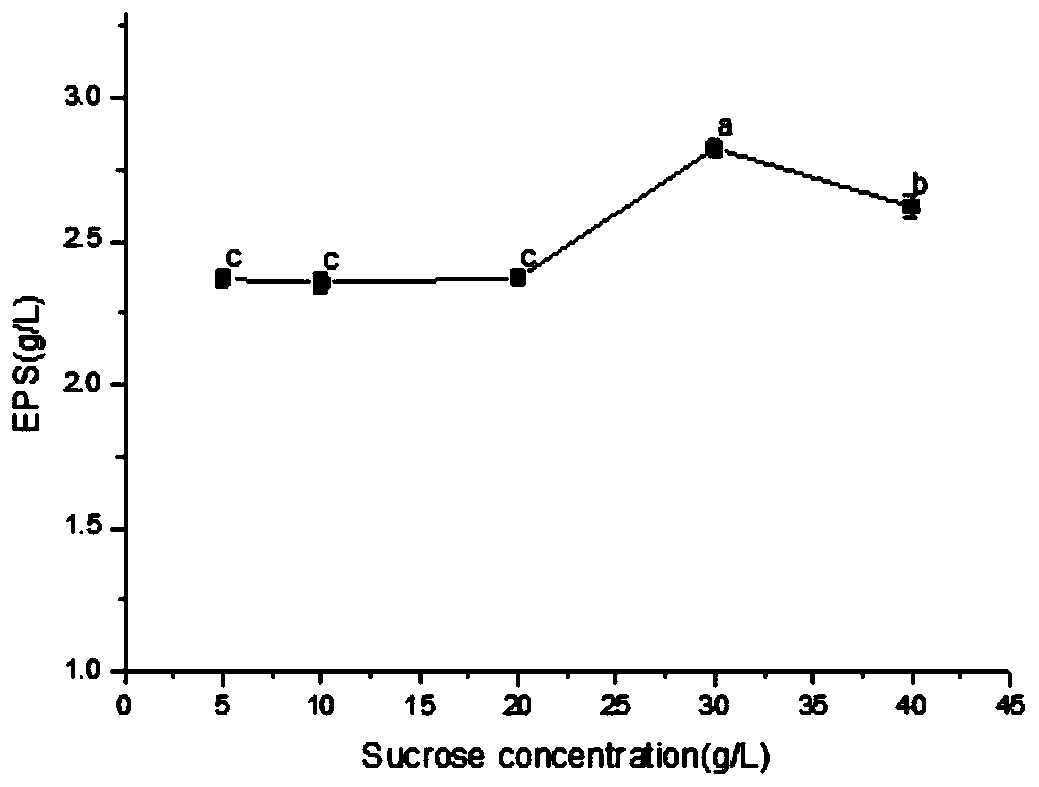

Sucrose content 2.8255±0.03 a

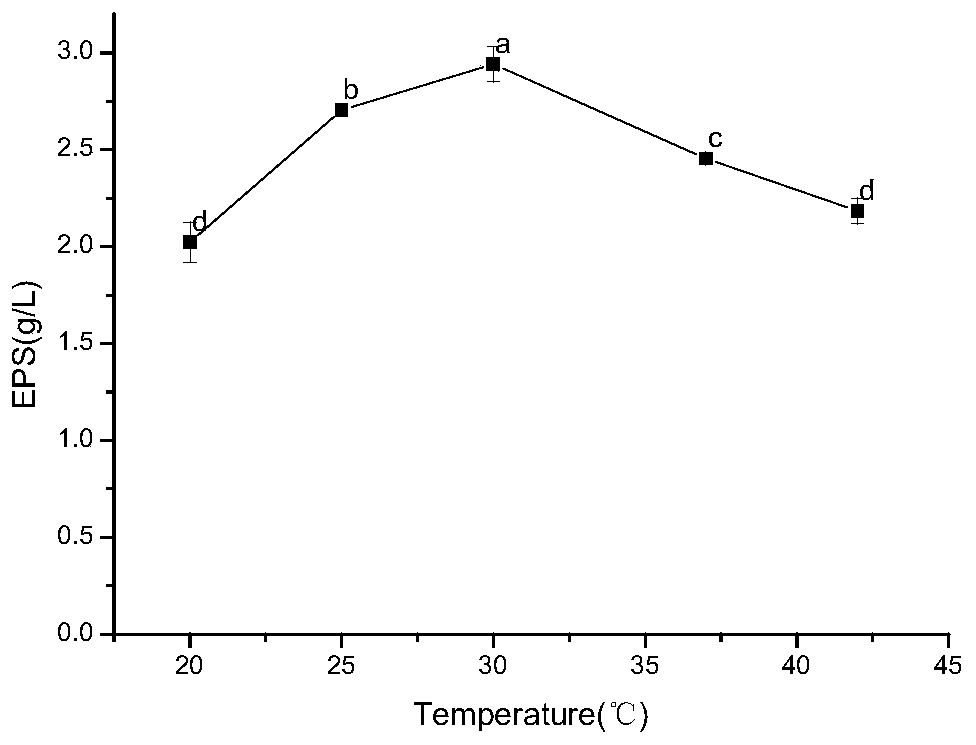

fermentation temperature 2.9417±0.09 a

fermentation time 2.6694±0.001 a

[0081] The composition of the improved MRS liquid medium: soybean peptone 10.0g / L, beef extract 10.0g / L, yeast extract 5.0g / L, sucrose 30g / L, K 2 PO 4 2.0g / L, sodium acetate 5.0g / L, triammonium citrate 2.0g / L, MgSO 4 ·7H 2 O is 0.58g / L, MnSO 4 4H 2 O is 0.25g / L, Tween-80 is 1.0mL / L, ...

Embodiment 2

[0092] The cholesterol-lowering qualitative method of embodiment 2 Lactobacillus plantarum La-10 exopolysaccharide

[0093] When the inoculum size was 4%, the sucrose content was 30g / L, the fermentation time was 30h, and the fermentation temperature was 30°C, La-10 was cultured statically in the improved MRS liquid medium to extract purified and freeze-dried EPS powder.

[0094] Weigh 0.8g / L of EPS solid powder into a 15mL clean centrifuge tube, and add 10mL of cholesterol standard solution (1mg / mL), and use no exopolysaccharide as a control. Under the condition of constant temperature, oscillating and adsorbing at 30°C for 15 hours, centrifuging at 10000rpm for 6 minutes, taking the supernatant, measuring the cholesterol content of the supernatant by the o-phthalaldehyde method, and using the above formula to calculate the cholesterol adsorption rate of La-10 exopolysaccharide is 41.45 %±1.3%.

[0095] Phthalaldehyde method: absorb 500 μL of supernatant, dilute the solution ...

Embodiment 3

[0097] Embodiment 3 Lactobacillus plantarum La-10 liquid static fermentation produces EPS

[0098] Lactobacillus plantarum La-10 was inoculated in the improved MRS liquid medium at an inoculum size of 5% by volume, at a fermentation temperature of 31° C., and cultured statically for 35 hours, wherein the sucrose content in the improved MRS liquid medium was 34 g / L.

[0099] MRS liquid medium composition: soybean peptone 10.0g / L, beef extract 10.0g / L, yeast extract 5.0g / L, sucrose 34g / L, K 2 PO 4 2.0g / L, sodium acetate 5.0g / L, triammonium citrate 2.0g / L, MgSO 4 ·7H 2 O is 0.58g / L, MnSO 4 4H 2 O is 0.25g / L, Tween-80 is 1.0mL / L, pH6.2~6.4.

[0100] EPS extraction method is:

[0101] (1) Centrifuge at 4°C and 8000r / min for 15min, take the supernatant and discard the bacterial precipitate.

[0102] (2) Add trichloroacetic acid (TCA) to the supernatant to a final mass fraction of 5%, and let stand overnight at 4° C. to remove proteins.

[0103] (3) Centrifuge at 4°C and 8000...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com