A kind of processing method of 6000 series aluminum alloy

A treatment method and aluminum alloy technology, which is applied in the field of intensive cold deformation multi-stage short-time solution treatment to refine the grains of 6000 series aluminum alloys, and can solve the problems of easy oxidation of the surface, performance degradation, and coarsening of the second phase. , to achieve the effects of hindering grain growth, inhibiting grain boundary expansion, and promoting recrystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

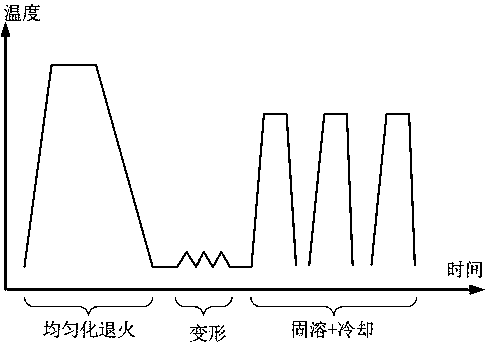

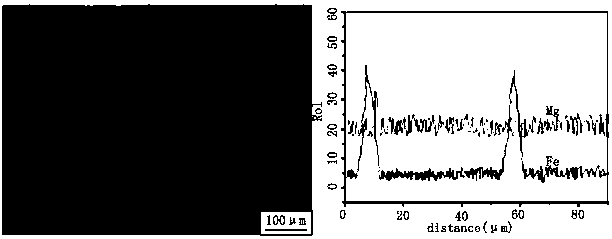

[0032] according to figure 1 The grain refinement process shown uses Al-Mg-Si alloy as the rolling material. There are a large number of evenly distributed disperse phases in the sample structure homogenized at 570℃ for 7h, and the rolling deformation is realized by two-roll rolling. The billet is subjected to rapid multi-pass rolling to achieve a deformation of 90%, and then a solid solution recrystallization treatment (three-stage treatment) is carried out at 560 ° C for 10 minutes. °C / s, Image 6 Its metallographic structure, the average grain size of the alloy at this time is 10.2 μm. In order to verify the material properties after the refining process, the plate was finally subjected to 540 ℃ × 5min solution and T4p aging treatment, and the mechanical properties of the aging plate were tested, as shown in Table 1. It can be seen from the above that, compared with the traditional hot rolling process, the process of the present invention can obtain higher strength, and ...

Embodiment 2

[0034] according to figure 1 In the shown grain refining process, Al-Mg-Si alloy is used as the experimental material, wherein the homogenization and compression treatment processes are the same as those in Example 1. The difference is that the rolled samples are respectively subjected to solid solution recrystallization treatment (secondary treatment) at 560 °C for 10 minutes. Figure 7 Its metallographic structure, the average grain size of the alloy at this time is 14.2 μm. In order to verify the material properties after the refining process, the plate was finally subjected to 540 ℃ × 5min solution and T4p aging treatment, and the mechanical properties of the aging plate were tested. At this time, the tensile strength and yield strength of the plate were 227MPa and 109MPa, respectively. , which is lower than that in Example 1. It can be seen that the secondary solid solution recrystallization treatment fails to completely refine the grain structure, and there is still a p...

Embodiment 3

[0036] according to figure 1 In the shown grain refining process, Al-Mg-Si alloy is used as the experimental material, wherein the homogenization and rolling treatment processes are the same as those in Example 1. The difference is that the rolled samples are respectively subjected to solid solution recrystallization treatment (three-stage treatment) for 15 minutes at 560 °C. Figure 8 Its metallographic structure, the average grain size of the alloy at this time is 11.6 μm. In order to verify the material properties after the refining process, the plate was finally subjected to 540 ℃ × 5min solution and T4p aging treatment, and the mechanical properties of the aging plate were tested. At this time, the tensile strength and yield strength of the plate were 214MPa and 107MPa, respectively. . Under this treatment process condition, the grain size is comparable to that of Example 1, indicating that the Al-Mg-Si alloy is not easy to be recrystallized and coarsened, but the mecha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com