Full-rotating dynamic pointing type rotating guide system and guide controlling method

A rotary steerable and dynamic steerable technology, applied in the technical fields of directional drilling and rotary steerable drilling, can solve problems such as the strength of the drill string is not as good as that of the push-on type, the direction of the drill bit is deflected, and the build-up rate of hard formations is low. The effect of simple structure and accurate guiding direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

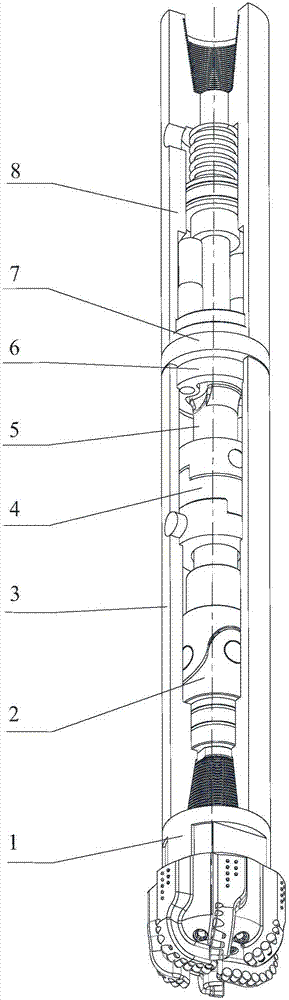

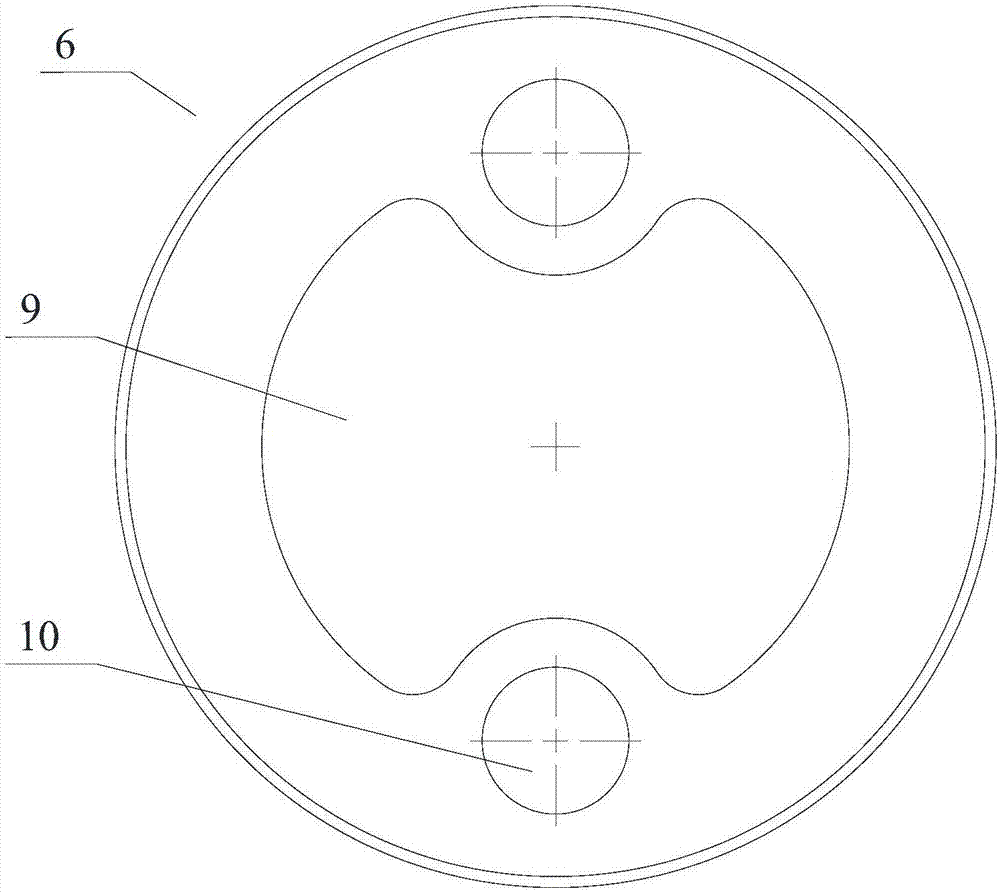

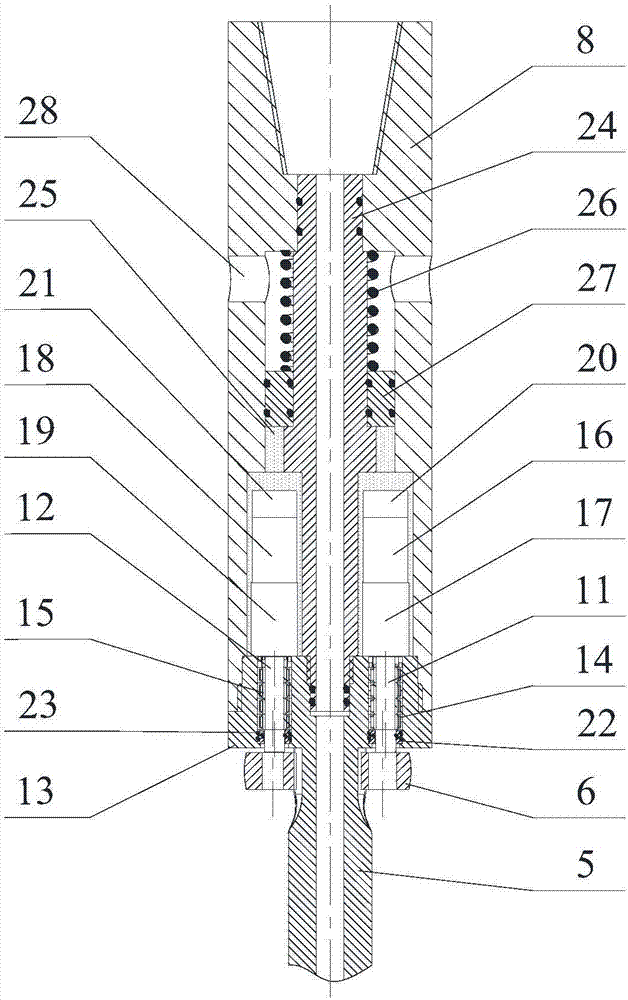

[0039] Such as figure 1 As shown, the full-rotation dynamic pointing type rotary steering system disclosed in the present invention includes a drill bit 1, a universal joint 2, a lower housing 3, a cross slider mechanism 4, a transmission shaft 5, a balance wheel 6, a guide drive mechanism 7, The upper casing 8; the drill bit 1 is fixedly connected with the lower casing 3; the lower casing 3 is fixedly and sealed connected with one end of the universal joint 2; the yaw wheel 6 is installed inside the lower casing 3 and the outer side of the drive shaft 5, and connected with the output end of the guide drive mechanism 7; the other end of the universal joint 2 is fixedly connected with the drive shaft 5; the drive shaft 5 is fixed and sealed with one end of the guide drive mechanism 7, or connected The drive mechanism 7 is integrated, and the other end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com