Metal tile water lubricating friction pair structure

A technology of water lubrication and friction pair, which is applied in the field of metal tile water lubrication friction pair structure, which can solve the problems of friction pair damage, concave deformation, excessive wear increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

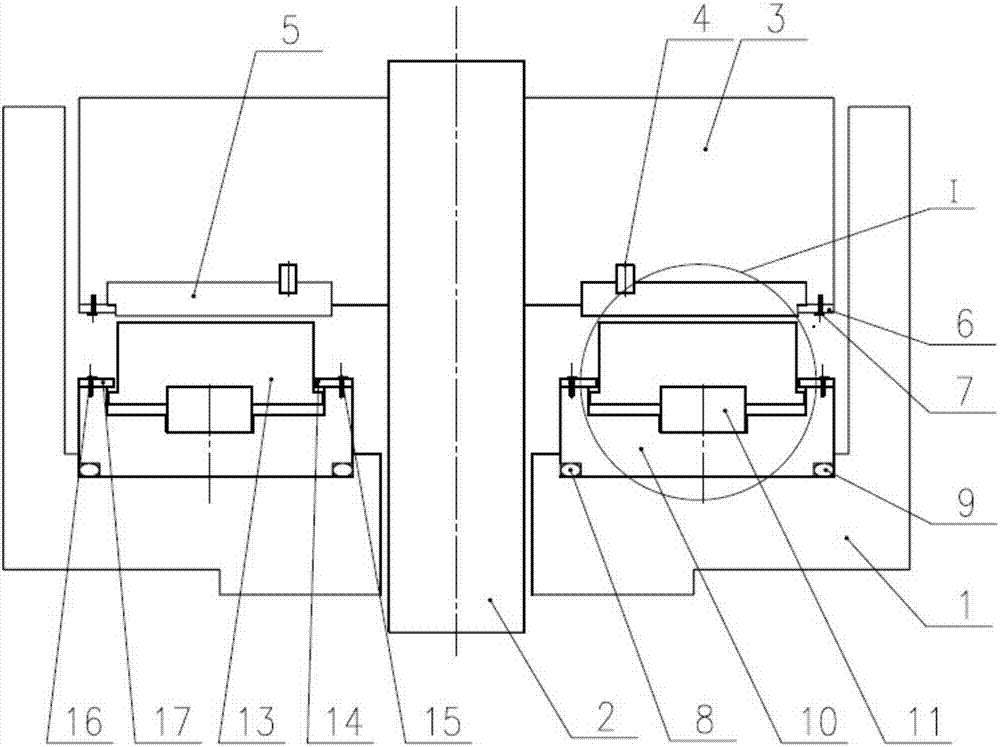

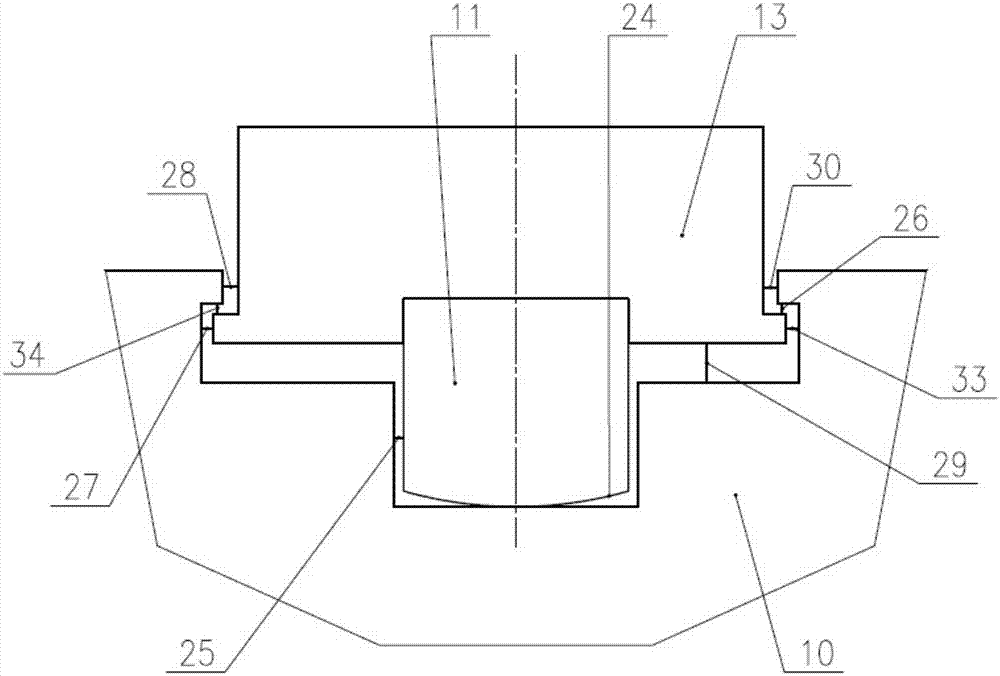

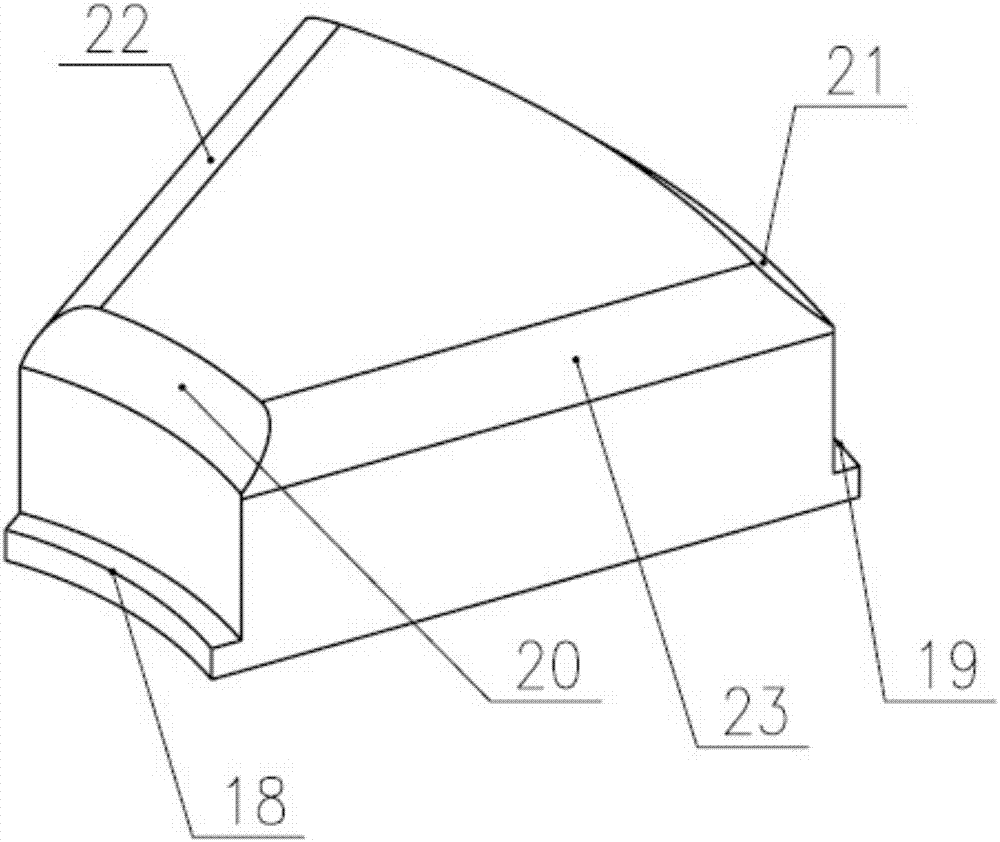

[0019] figure 1 It is a metal tile water-lubricated friction pair structure, that is, the thrust plate 3 is installed on the shaft 2, the positioning pin 4 is installed on the thrust plate 3 with interference, and the non-metallic thrust surface 5 is fixed on the thrust plate 3 through the positioning pin 4 , the first pressure ring 6 is connected to the bottom of the thrust plate 3 through the first bolt 7; the support block 11 is arranged at the bottom of the thrust pad 13, and the support block 11 is installed on the bearing seat 10, and the second pressure ring 17 is closed through the second bolt 16 On the upper side of the outer circle of the bearing seat 10, the third pressure ring 14 is connected to the upper side of the inner circle of the bearing seat 10 by the third bolt 15; the bearing seat 10 is installed above the machine base 1, and the bottom of the inner circle of the bearing seat 10 is installed with the first O-type seal ring 8, the second O-type seal ring 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com