Heat pump drying and dehumidifying all-in-one machine

A technology of heat pump drying and all-in-one machine, which is applied in the direction of dryer, drying, drying gas arrangement, etc., which can solve the problem that the dehumidification effect cannot be effectively guaranteed, the humid air drops below the dew point temperature, and cannot be effectively controlled in real time To achieve high drying and dehumidification efficiency, ensure water vapor condensation, and good dehumidification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following are specific embodiments of the present invention in conjunction with the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

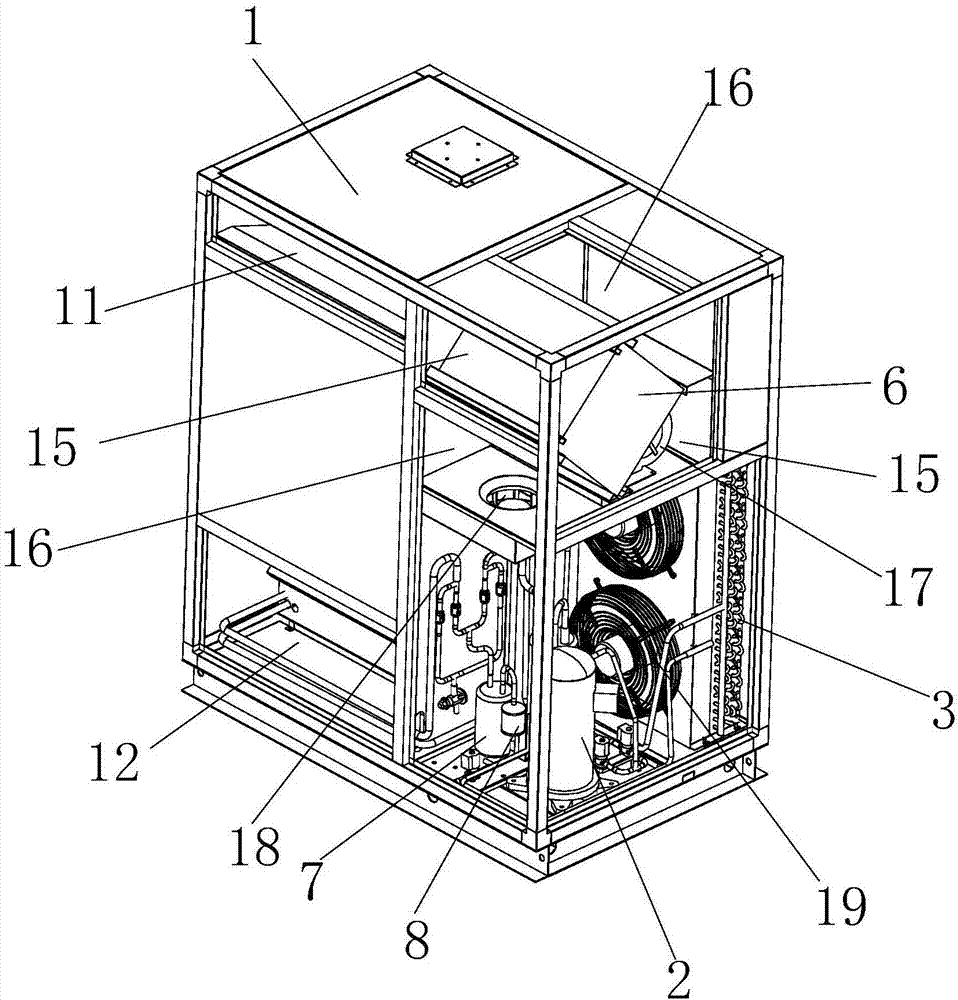

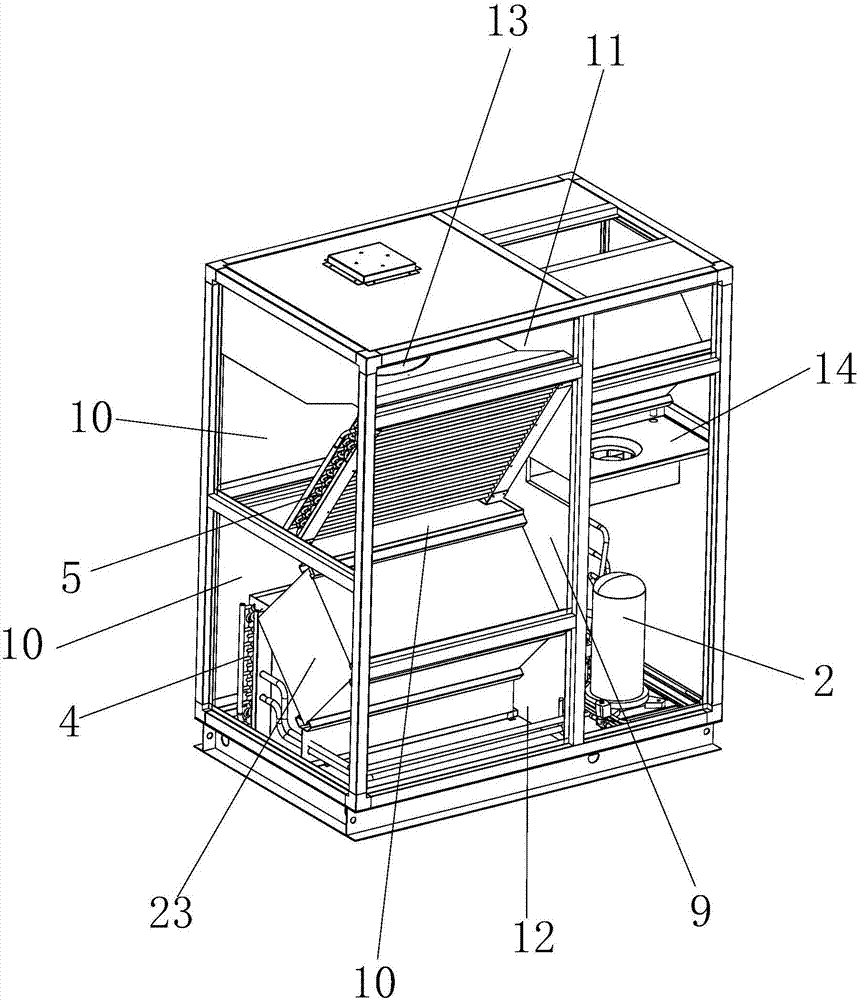

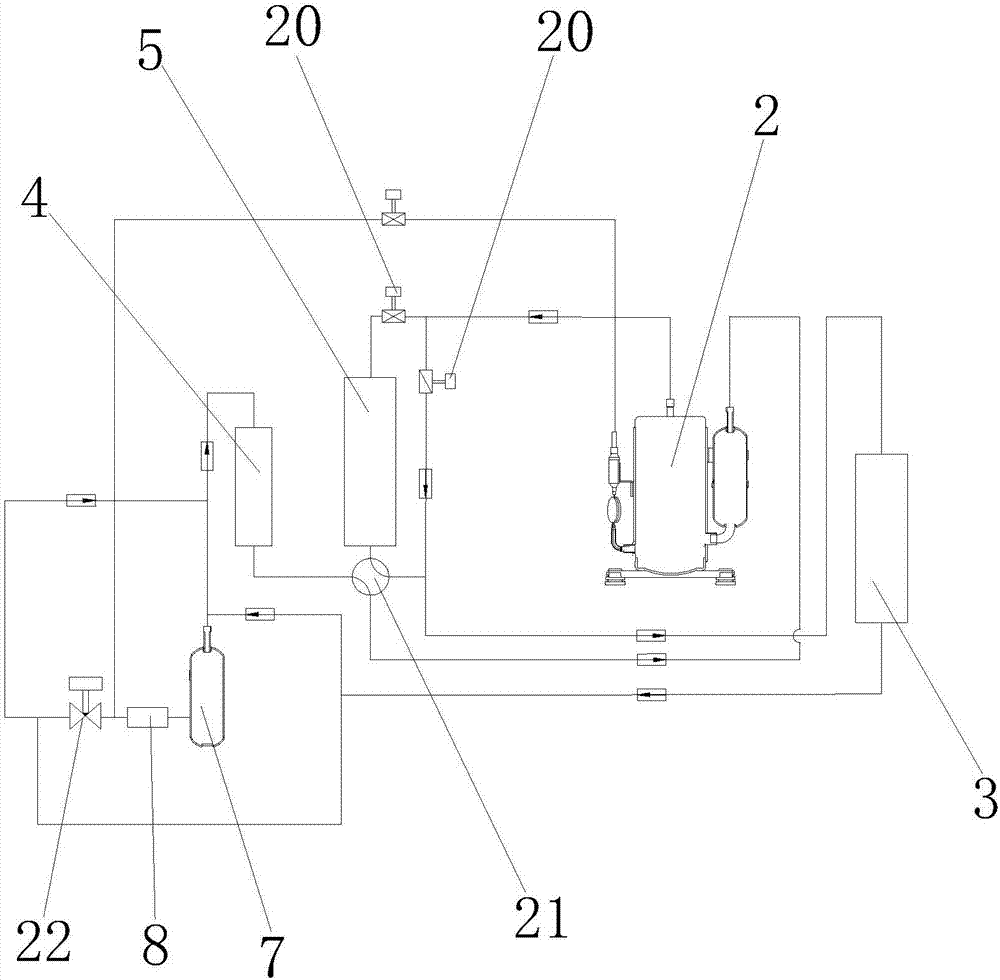

[0031] Such as figure 1 with figure 2 As shown, the heat pump drying and dehumidification integrated machine provided by the present invention can realize the functions of heating, cooling, dehumidification, dehumidification, ventilation, humidification, electric heating, defrosting, etc. It mainly includes a PLC control system, a body 1, and The compressor 2, the first heat exchanger 3, the second heat exchanger 4, the third heat exchanger 5, the fourth heat exchanger 6, the control valve group, the liquid reservoir 7 and the filter drier arranged in the body 1 8.

[0032] The body 1 is divided into left and right parts by a large partition 9. The left side is an internal circulation air duct 10. The second heat exchanger 4 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com