A bridge crack detection device and detection method

A detection method and bridge technology, applied in the direction of optical testing flaws/defects, etc., can solve the problems of affecting the judgment of bridge structure safety bearing capacity, bridge operation quality evaluation results, inability to objectively evaluate the effective basis of road surface quality, and inaccurate measurement detection. , to achieve the effect of simple structure, low investment cost and rapid detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

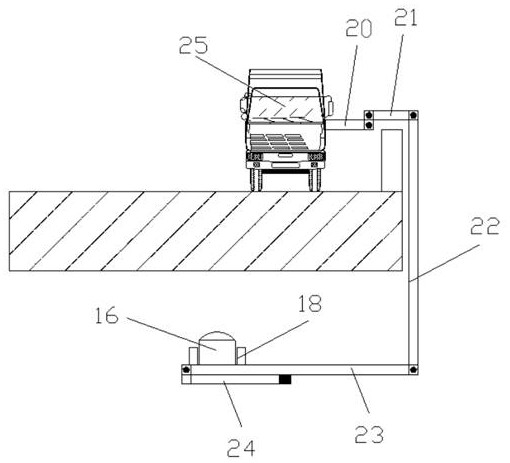

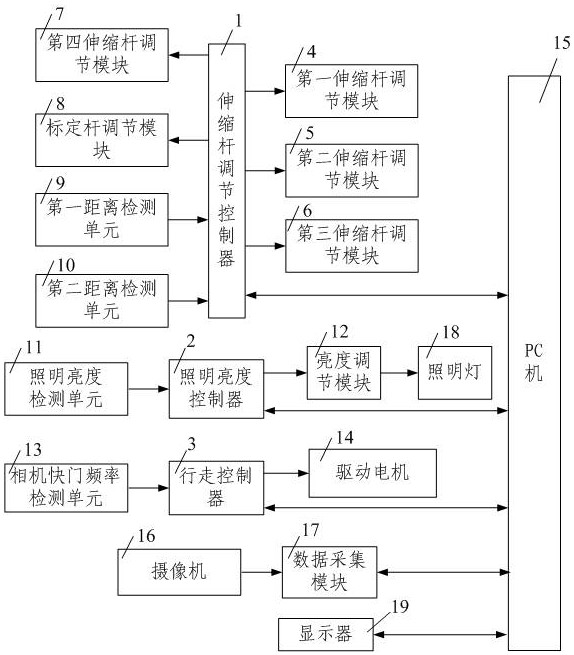

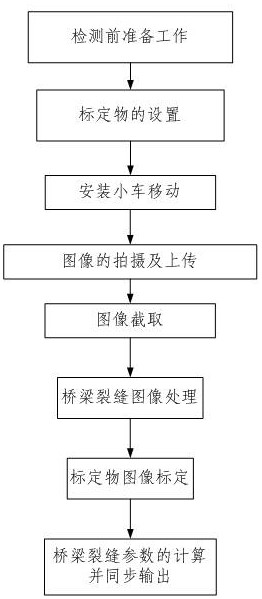

[0071] Such as figure 1 with figure 2 A bridge crack detection device shown includes a control device, an installation trolley 25 moving along the bridge to be detected, a telescopic rod mechanism installed on the installation trolley 25, and a telescopic rod mechanism installed on the telescopic rod mechanism in the bridge to be detected. A detection device for automatic detection of bridge cracks, the telescopic rod mechanism includes a first telescopic rod 20 installed on the installation trolley 25 and arranged horizontally, a second telescopic rod 21 connected to the first telescopic rod 20 and a second telescopic rod 21 connected to the first telescopic rod 25 The third telescopic rod 22 connected with the second telescopic rod 21 and arranged vertically with the second telescopic rod 21, and the fourth telescopic rod 23 connected with the third telescopic rod 22 and arranged vertically with the third telescopic rod 22 and the fourth telescopic rod 23 connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com