Laser direct writing data processing system and processing method

A data processing system and laser direct writing technology, applied in optics, opto-mechanical equipment, microlithography exposure equipment, etc., can solve the problems of large data transmission, long data link, and many fault points, and shorten the data link. The effect of reducing the number of roads, reducing nodes, and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

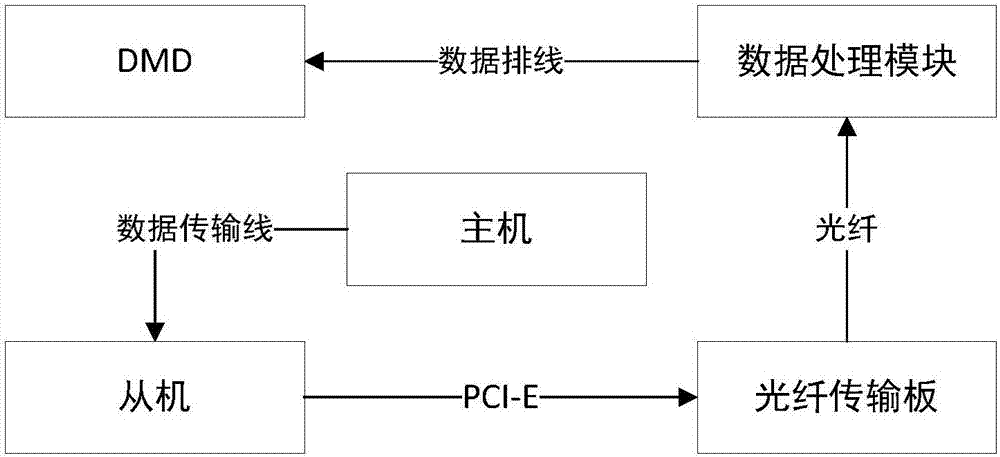

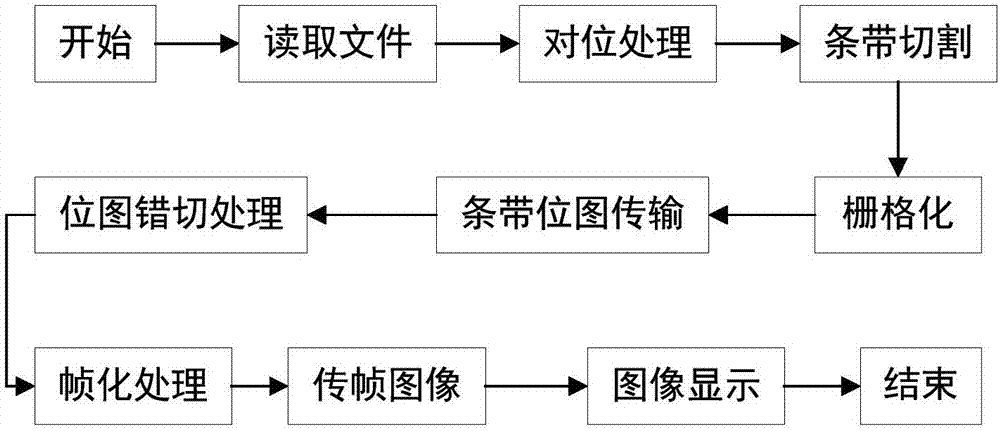

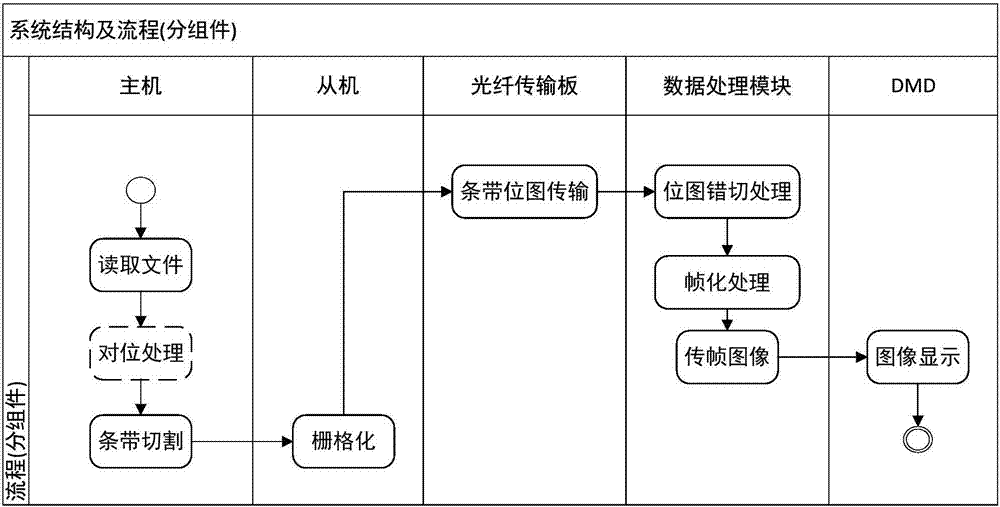

[0055] This embodiment provides a laser direct writing data processing system according to the technical solution of the present invention, as shown in the attached Figure 4 As shown, the system includes a host, a data processing module and a DMD.

[0056] Among them, the data processing module is composed of data receiving unit, FPGA V6, DDR and DLP chipset (see attached Figure 5 )——FPGA V6 is the data processing unit, the model is XC6VLX240T, and DDR is the storage unit. The DLP chipset includes two DLP chips, a FLASH chip and an FPGA V5 chip (see attached Figure 6 )——The FLASH chip is a program storage chip, and the FPGA V5 chip is an image transmission chip.

[0057] The host generally can be a PC, various servers or various industrial computers. By carrying a software system, the host computer can perform corresponding data processing.

[0058] DMD is a commonly used SLM. Under the action of the light source, the DMD projects the received frame image onto the subs...

Embodiment 2

[0078] This embodiment provides another laser direct writing data processing system according to the technical solution of the present invention. Compared with Embodiment 1, the system of this embodiment has some changes in the structure of the data processing module, as shown in the attached Figure 9 As shown, the data processing module in this embodiment is composed of a data receiving unit, an ARM+FPGA, a DDR and a DLP chipset.

[0079] Wherein, the ARM+FPGA corresponds to the FPGA V6 in Embodiment 1, and is a data processing unit, and the ARM+FPGA can also be replaced by an SoC chip, and the mainstream SoC chip manufacturers are Altera or Xilinx.

[0080] In Embodiment 1, the host completes the rasterization of graphics, which requires high computing power of the host; the solution in Embodiment 1 does not support the working conditions of multiple DMDs. However, if the rasterization work is performed by the FPGA, the development of the FPGA is more difficult. In this em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com