Atomic layer etching 3D structures: si and sige and ge smoothness on horizontal and vertical surfaces

An etching and surface modification technology, which is applied in coating, metal material coating process, gaseous chemical plating, etc., can solve the problems of lateral etching material damage and affecting device performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0120] In the following description, numerous specific details are set forth in order to provide a thorough understanding of the presented embodiments. The disclosed embodiments may be practiced without some or all of these specific details. In other instances, well known process operations have not been described in detail so as not to unnecessarily obscure the disclosed embodiments. While the disclosed embodiments will be described in conjunction with specific embodiments, it will be understood that it is not intended to limit the disclosed embodiments.

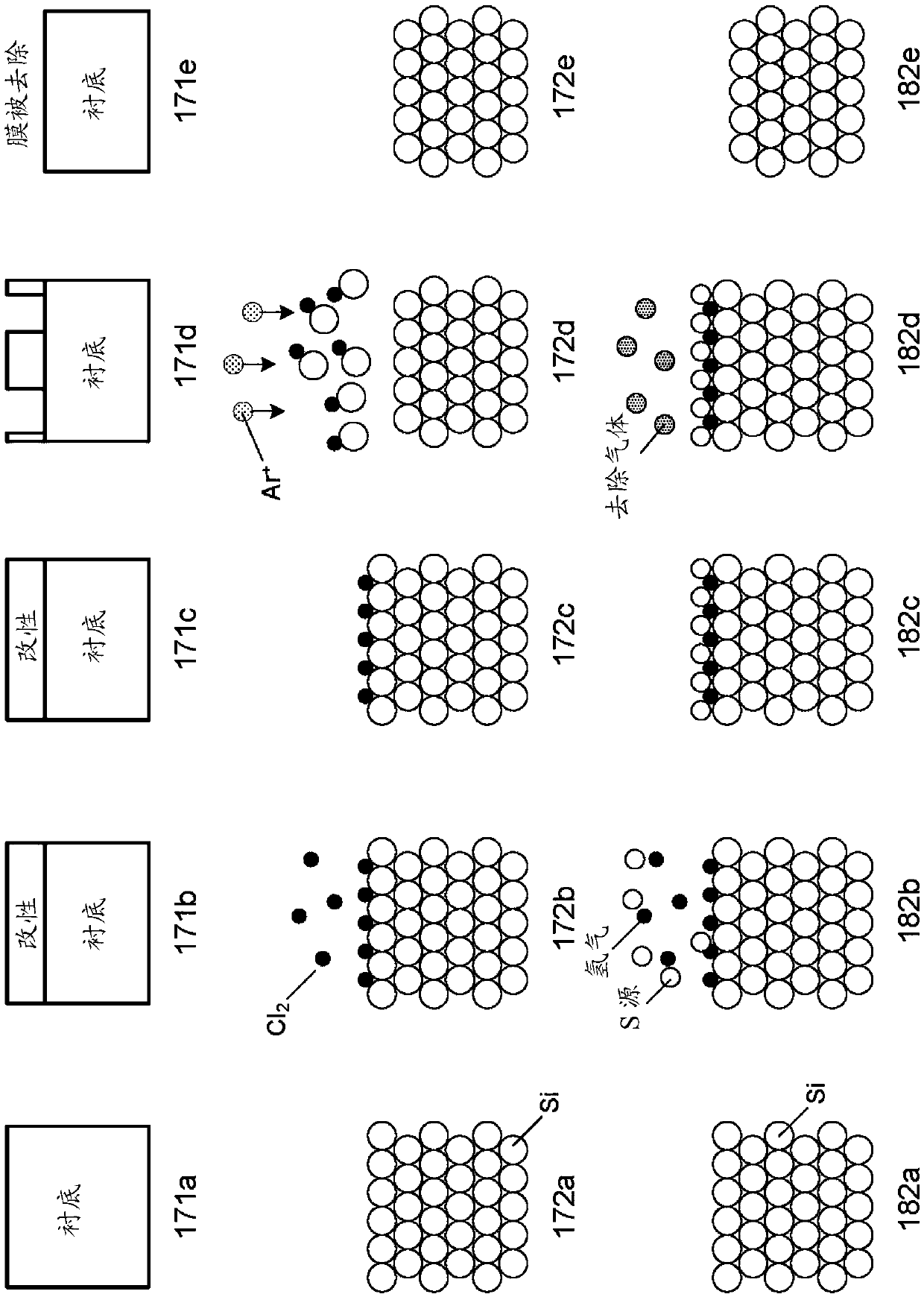

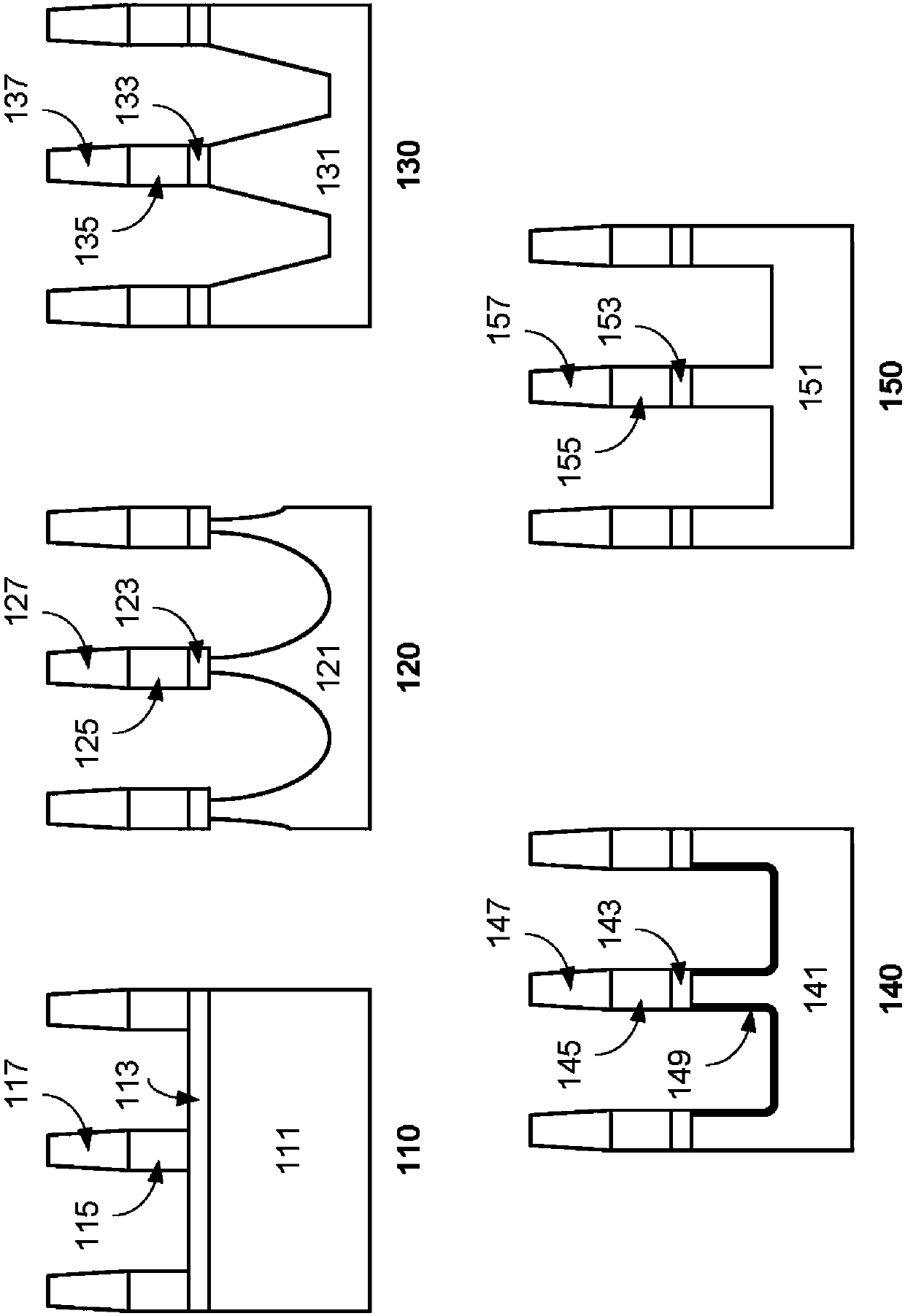

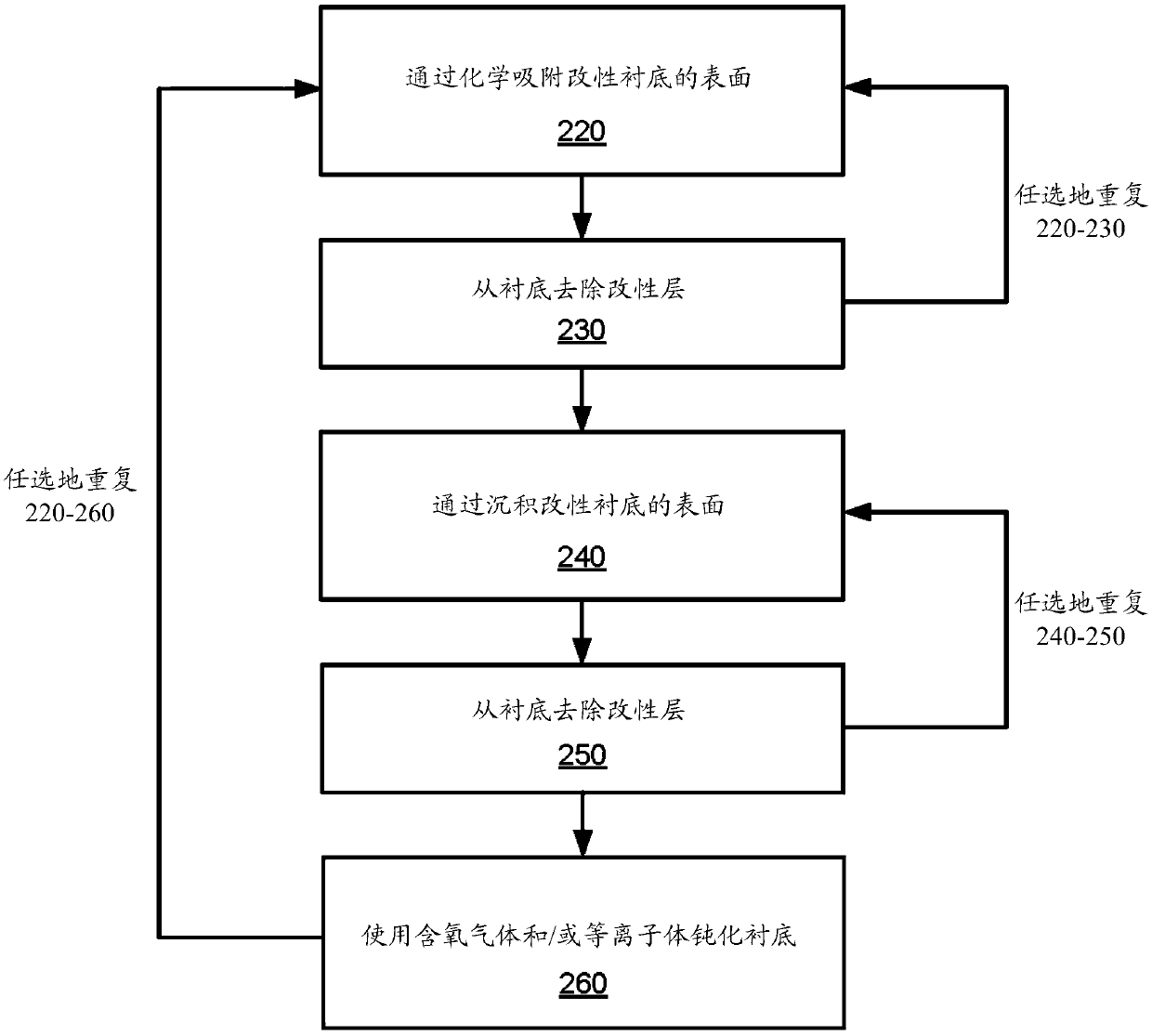

[0121] Semiconductor device fabrication processes generally involve etching processes for forming various structures on semiconductor substrates. Conventional plasma etching processes typically involve continuous etching of materials, but are particularly prone to transport limitations and resulting roughness and damage to etched surfaces. During etching, conventional plasma etching processes combined with pulsing of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com