Nanoparticle latex and nanoparticle enhanced and toughened vinyl chloride composite resin and preparation method thereof

A nanoparticle and composite resin technology is applied in the field of preparation of nanoparticle reinforced and toughened vinyl chloride composite resin, which can solve the problems of poor product tensile strength, complicated reaction process, poor processing fluidity, etc. Simple, impact-resistant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

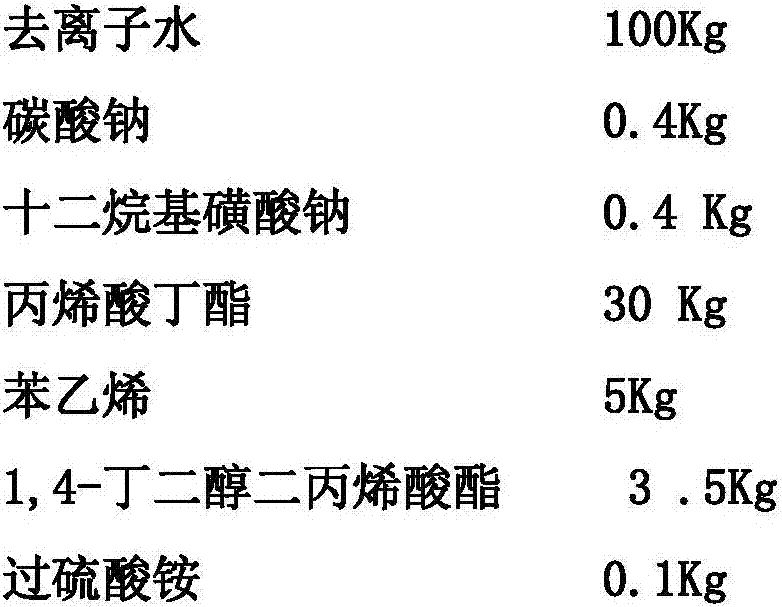

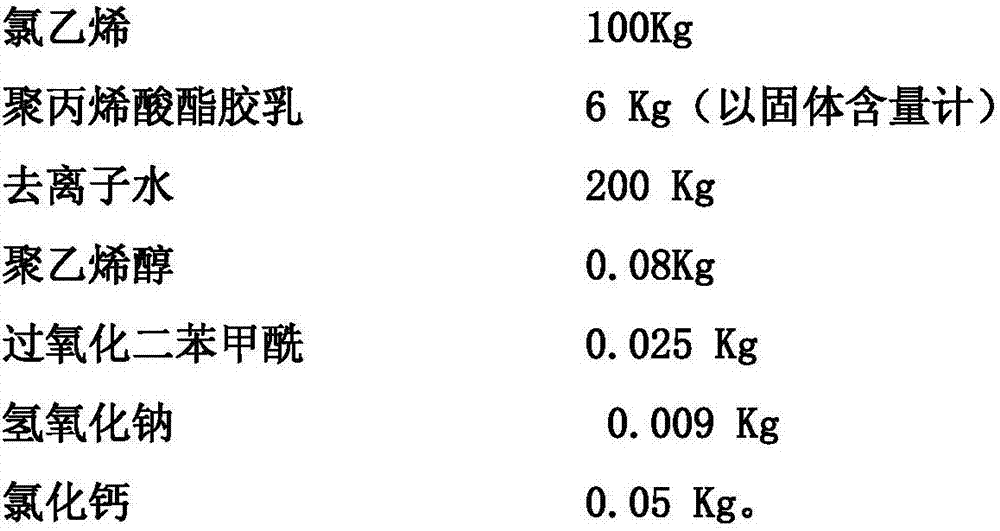

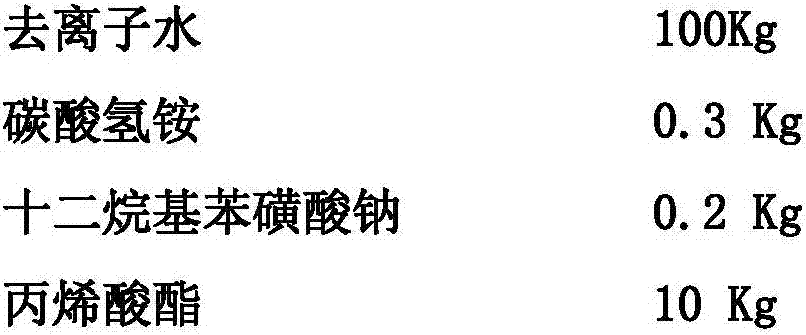

[0024] Example 1, the nanoparticle latex is obtained according to the following preparation method: the first step, the raw materials include by weight parts: 100 to 200 parts of deionized water, 0.2 to 0.5 parts of pH regulator, active nanoparticle components 1 to 60 parts of nucleating agent, 0.05 to 0.8 parts of emulsifier, 6 to 60 parts of acrylate, 0.06 to 0.6 parts of crosslinking agent, 0.0006 to 0.3 parts of initiator I; in the second step, the acrylate Dissolve in the cross-linking agent to form a mixed solution of acrylate and cross-linking agent; in the third step, in an inert gas atmosphere, use deionized water as a solvent, add active nanoparticle nucleating agent, emulsifier, initiator agent I, a pH regulator, and then dropwise add a mixture of acrylate and crosslinking agent therein, and finally carry out a polymerization reaction at a temperature of 65° C. to 95° C. for 2 hours to 3 hours to obtain nanoparticle latex.

Embodiment 2

[0025] Example 2, the nanoparticle latex is obtained according to the following preparation method: the first step, the raw materials include by weight: 100 parts or 200 parts of deionized water, 0.2 part or 0.5 part of pH regulator, active nanoparticle components 1 or 60 parts of nucleating agent, 0.05 or 0.8 parts of emulsifier, 6 or 60 parts of acrylate, 0.06 or 0.6 part of crosslinking agent, 0.0006 or 0.3 part of initiator I; in the second step, the acrylate Dissolve in the cross-linking agent to form a mixed solution of acrylate and cross-linking agent; in the third step, in an inert gas atmosphere, use deionized water as a solvent, add active nanoparticle nucleating agent, emulsifier, initiator Agent I, pH adjuster, and then drop the mixed solution of acrylate and crosslinking agent therein, and finally carry out polymerization reaction at 65°C or 95°C for 2 hours or 3 hours to obtain nanoparticle latex.

[0026] The nano particle latex that the present invention obtain...

Embodiment 3

[0027] Embodiment 3, as an optimization of the above embodiment, the active nanoparticle nucleating agent is an active inorganic nano seed nucleating agent, which is an inorganic rigid particle with a nanometer size of 20nm to 50nm. The cost of the present invention is lower by selecting inorganic nanoparticles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com