Biomass gasification system

A gasification system and biomass technology, applied in the field of biomass gasification system, can solve the problems of gas leakage and uneven feeding, and achieve the effects of uniform airflow, improving efficiency and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

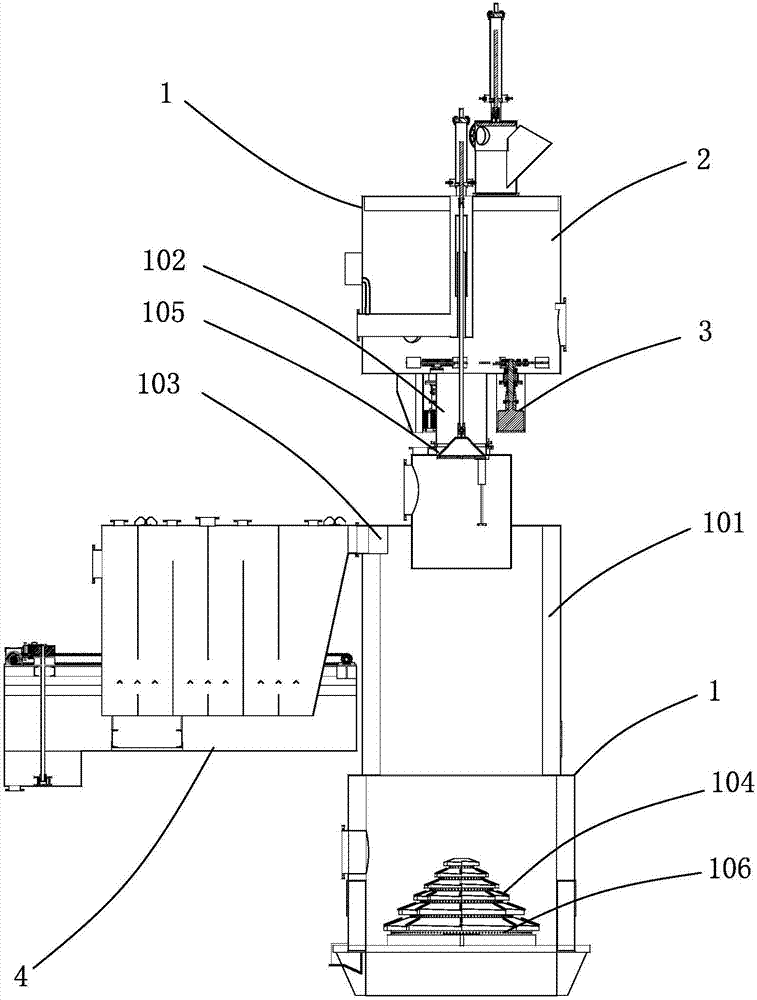

[0041] This embodiment provides a biomass gasification system, such as figure 1 As shown, it includes: a gasifier 1 , a feeding device 2 , a feeding mechanism 3 , and a gas purification device 4 .

[0042] Wherein, the gasification furnace 1 comprises a furnace body 101, a blanking pipeline 102, the furnace body 101 comprises a gas outlet 103, a fire grate 104, and a feed inlet 105, and the gas outlet 103 is arranged on the side wall of the furnace body 101 near the top part, and the furnace body The row 104 is arranged at the bottom of the furnace body 101, and an air inlet 106 is arranged on it, and the blanking pipe 102 is arranged on the top of the furnace body 101 corresponding to the feed inlet 105, and the top can be provided with a trumpet-shaped opening.

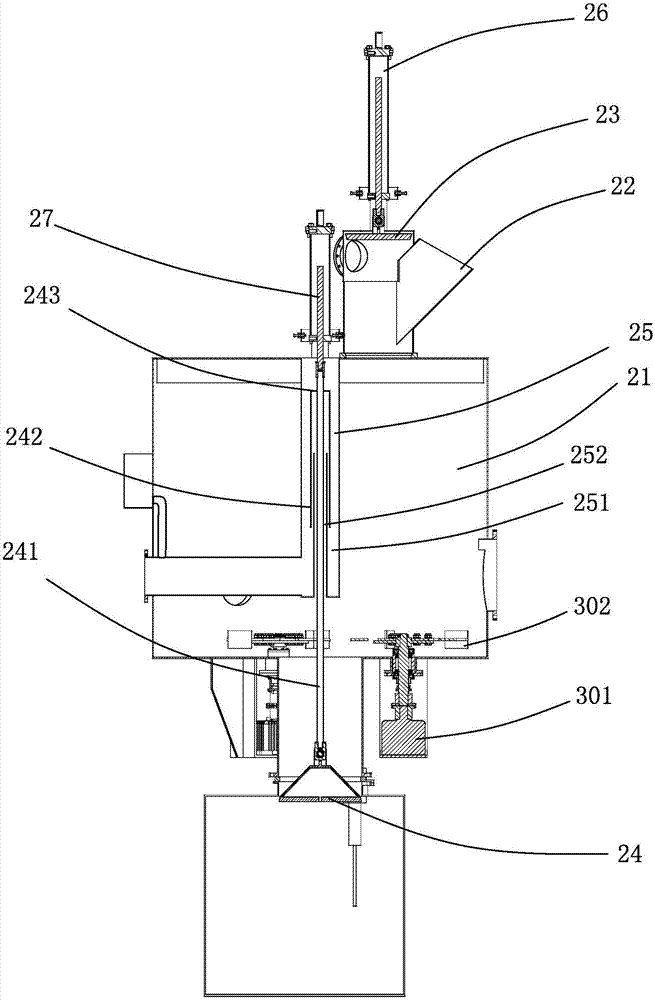

[0043] Such as figure 2 As shown, the feeding device 2 includes a storage bin 21, a feed pipeline 22, a first airtight door 23, a second airtight door 24, a sealing assembly 25, a first cylinder 26 for driving the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com