Method for increasing air-coupled ultrasonic detection signal strength of composite material

An air-coupling and ultrasonic testing technology, which is applied in the analysis of materials, the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, and the use of sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., to improve engineering practicability and improve detection sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described below in conjunction with accompanying drawing.

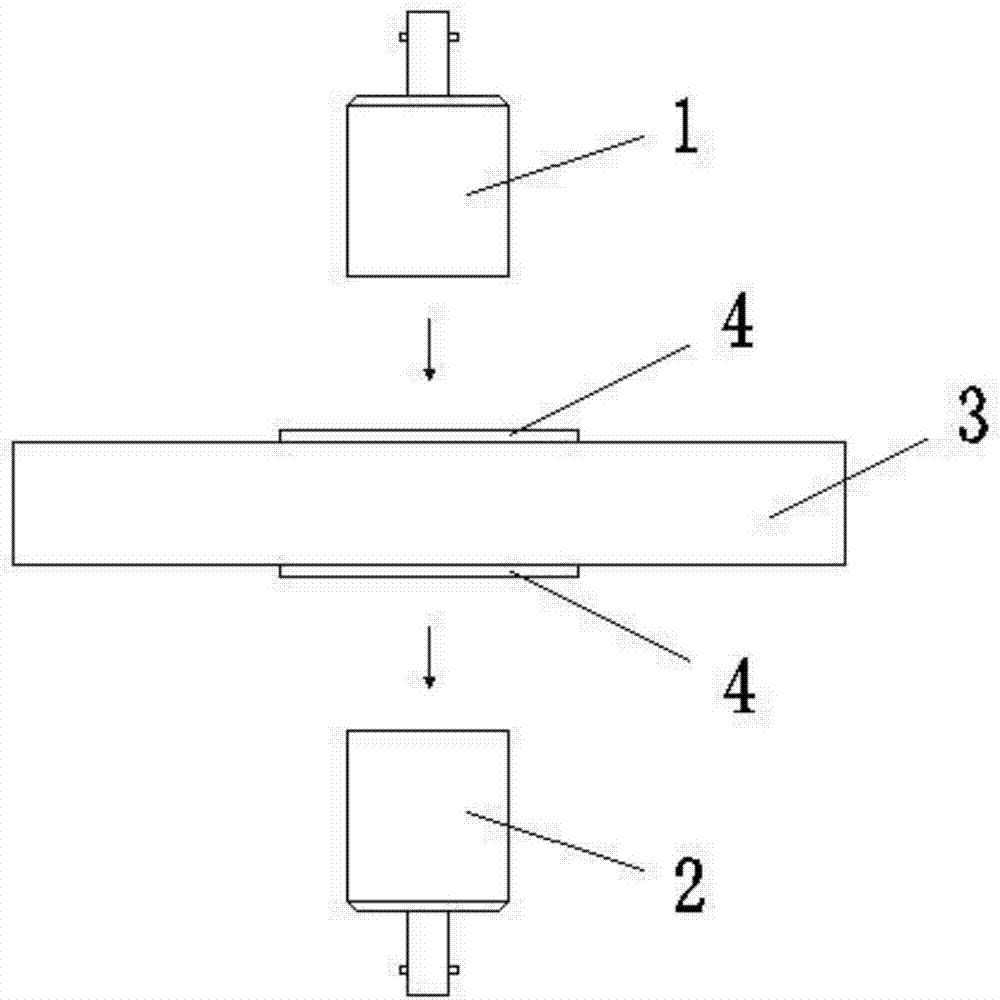

[0028] as attached figure 1 As shown, a method for increasing the air-coupled ultrasonic detection signal strength of a composite material according to the present invention comprises the following steps:

[0029] In the first step, the workpiece 3 is placed between the first air-coupled transducer 1 and the second air-coupled transducer 2;

[0030] In the second step, the film layer 4 is pasted on the upper and lower surfaces of the workpiece 3;

[0031] The third step is to excite the first air-coupled transducer 1, so that the ultrasonic waves emitted by it pass through the upper air, the upper film layer 4, the workpiece 3, the lower film layer 4 and the lower air in sequence, and reach the first Two air-coupled transducers 2;

[0032] In the fourth step, the signal received by the second air-coupled transducer 2 is fed back to the computer to generate images and data.

[0033] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com