Remote configurable large data collector in manufacturing environment and operation method thereof

A manufacturing environment and big data technology, applied in the direction of instruments, signal transmission systems, etc., can solve the problems of complex distribution of sensors, loss of internal configuration data, and inability to meet remote configuration, etc., to meet the real-time configuration requirements, easy to expand and modify , easily extendable and modifiable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with specific embodiments.

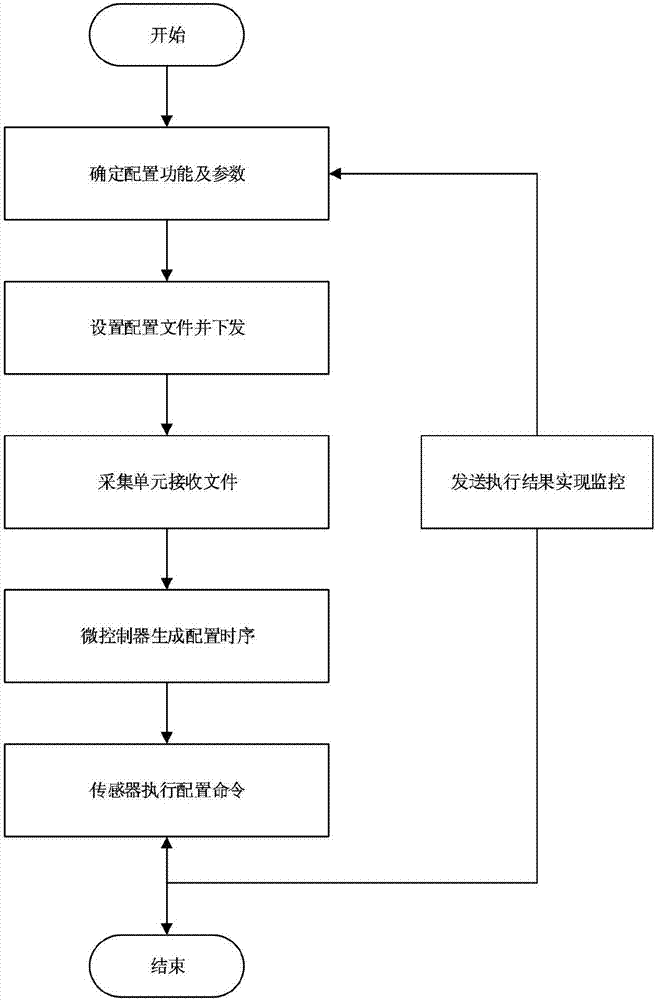

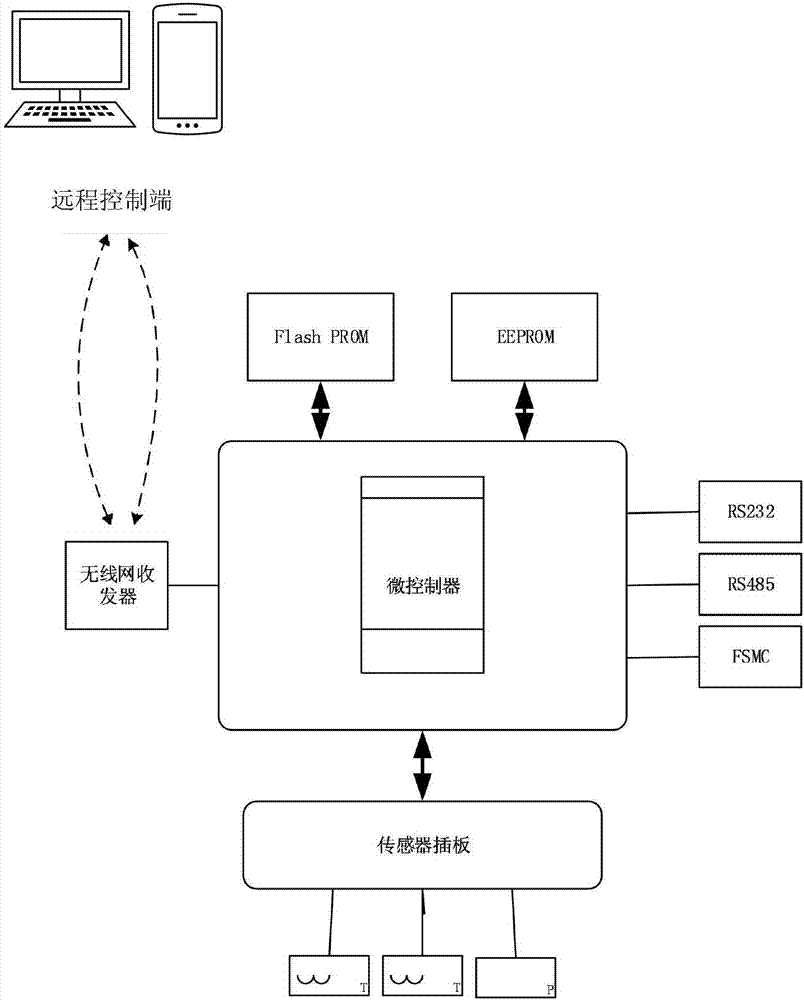

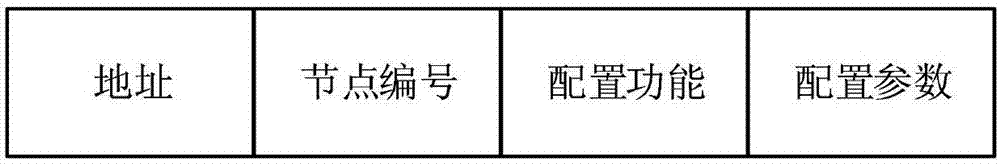

[0033] Figure 1 to Figure 3 ; It is the overall composition of the present invention: comprising an intelligent acquisition unit and a remote operation terminal deployed on the manufacturing site; the intelligent acquisition unit (embedded) transmits the collected data to the server through the data interaction module, and the server is the core component of data processing. On the top layer of the industrial manufacturing system, data can be exchanged with the acquisition unit through a wireless network or industrial Ethernet.

[0034] After the collected data is analyzed and processed in the server, the results and information will be transmitted to the human-computer interaction interface, and the user will make decisions and define some data that needs to be reconfigured based on these results, whether it is important, variable data or ordinary data.

[0035...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com