Oil-lubrication high-temperature air-cooling pile nuclear power plant main cooling fan motor

A technology for high-temperature gas-cooled reactors and cooling fans, applied in cooling/ventilation devices, asynchronous induction motors, electromechanical devices, etc., can solve the problem that the power of the helium compressor fan motor is small, it cannot be applied to high-power commercial reactor types, and it is not suitable for batch production Production and other problems, to achieve the effect of eliminating air seal design, eliminating oil leakage and oil atomization in the bearing chamber, and improving operation safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

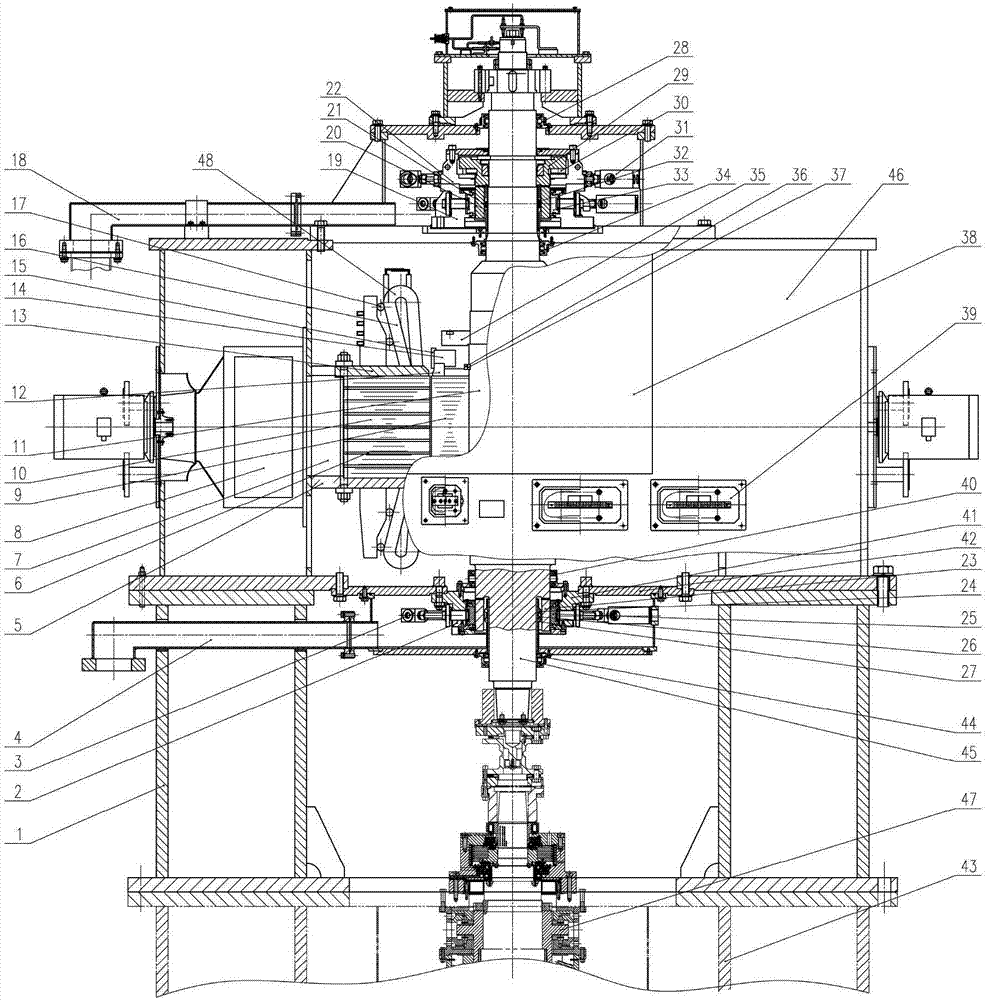

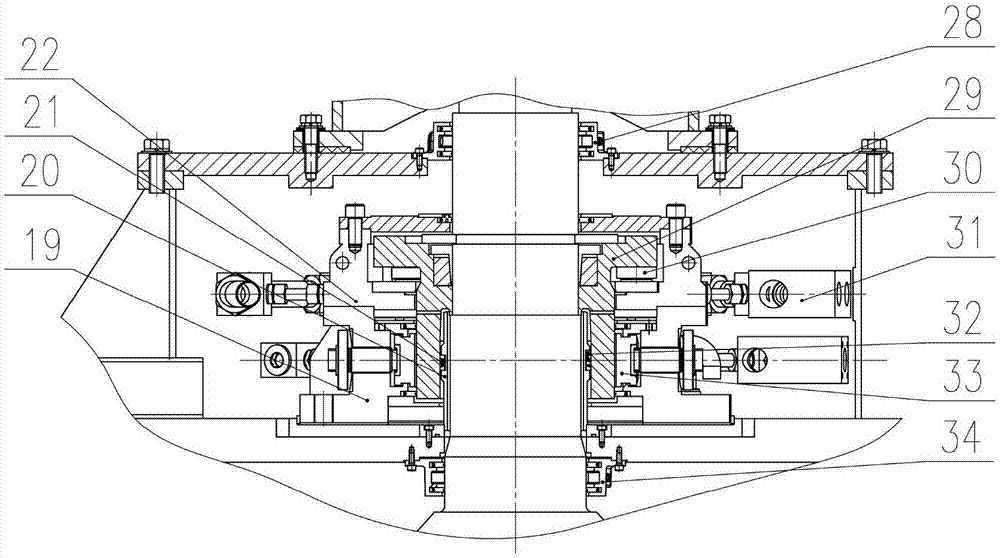

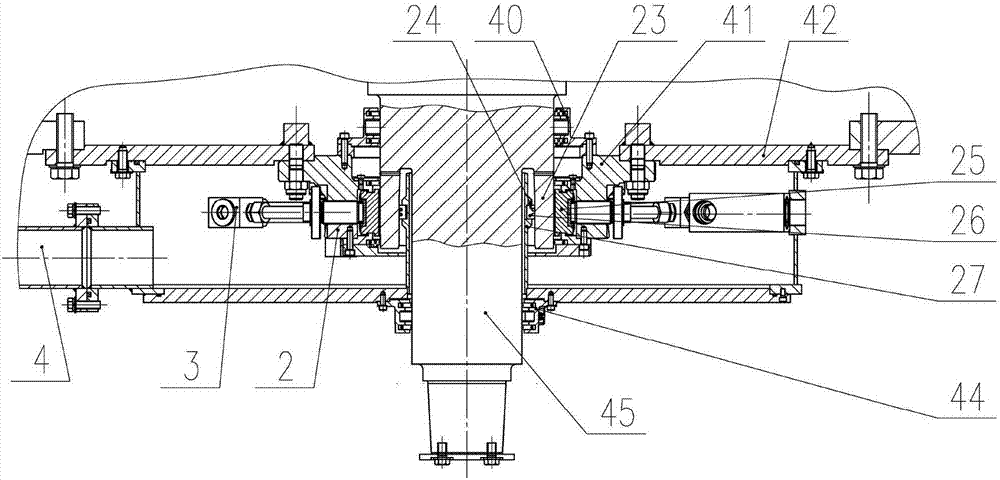

[0018] like figure 1Shown is an oil-lubricated high-temperature gas-cooled reactor nuclear power plant main cooling fan motor, which consists of a stator 5, a rotor 11, an upper guide thrust combined bearing 19, a lower guide bearing 43, a cooler 8, a motor support 1, and a stator outlet box 38 And main components such as auxiliary outlet box 39 are formed. The motor model is YLH4500-2, rated power 4500kW, rated voltage 6.0kV, rated current 515A, rated speed 4000r / min, working speed range 800-4200r / min, 3-phase, insulation class H.

[0019] The motor stator 5 includes a stator base 46, a stator core 10 and a stator winding 16. The stator core 10 is located inside the stator base 46, the stator winding 15 is embedded in the slot of the stator core 10, and the stator base 46 is mainly welded by steel plates. , the stator base 46 is provided with multiple ribs to improve the rigidity and strength of the base, the stator core 10 is made of stator punches coated with insulating pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com