A processing device for a solid conductor heat sink

A processing device and solid conductor technology, which is applied to the attachment of shearing machines, shearing devices, metal processing equipment, etc., can solve the problems of high difficulty in clamping, positioning, slow processing speed, and low processing efficiency, and achieve stable processing. , The effect of high processing efficiency and high processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

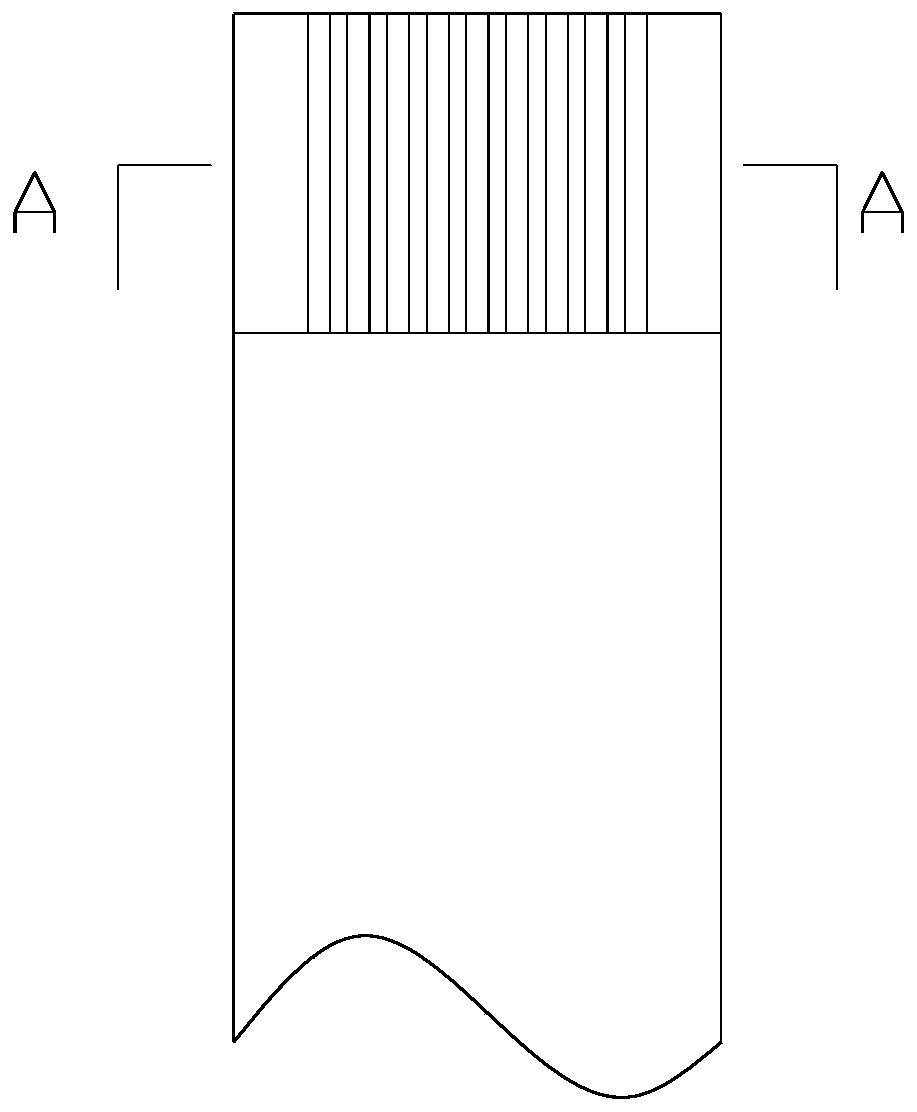

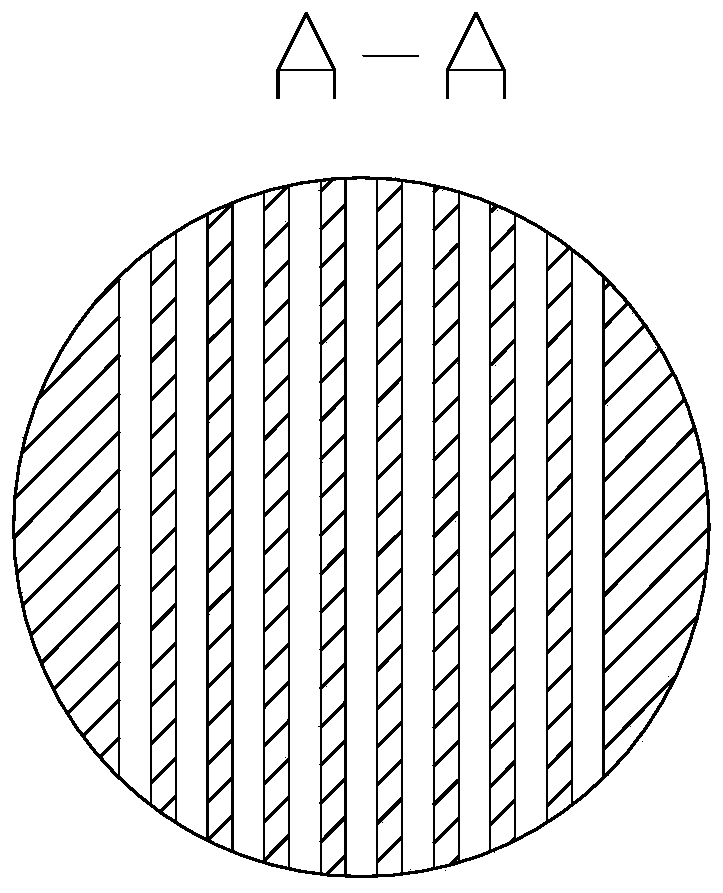

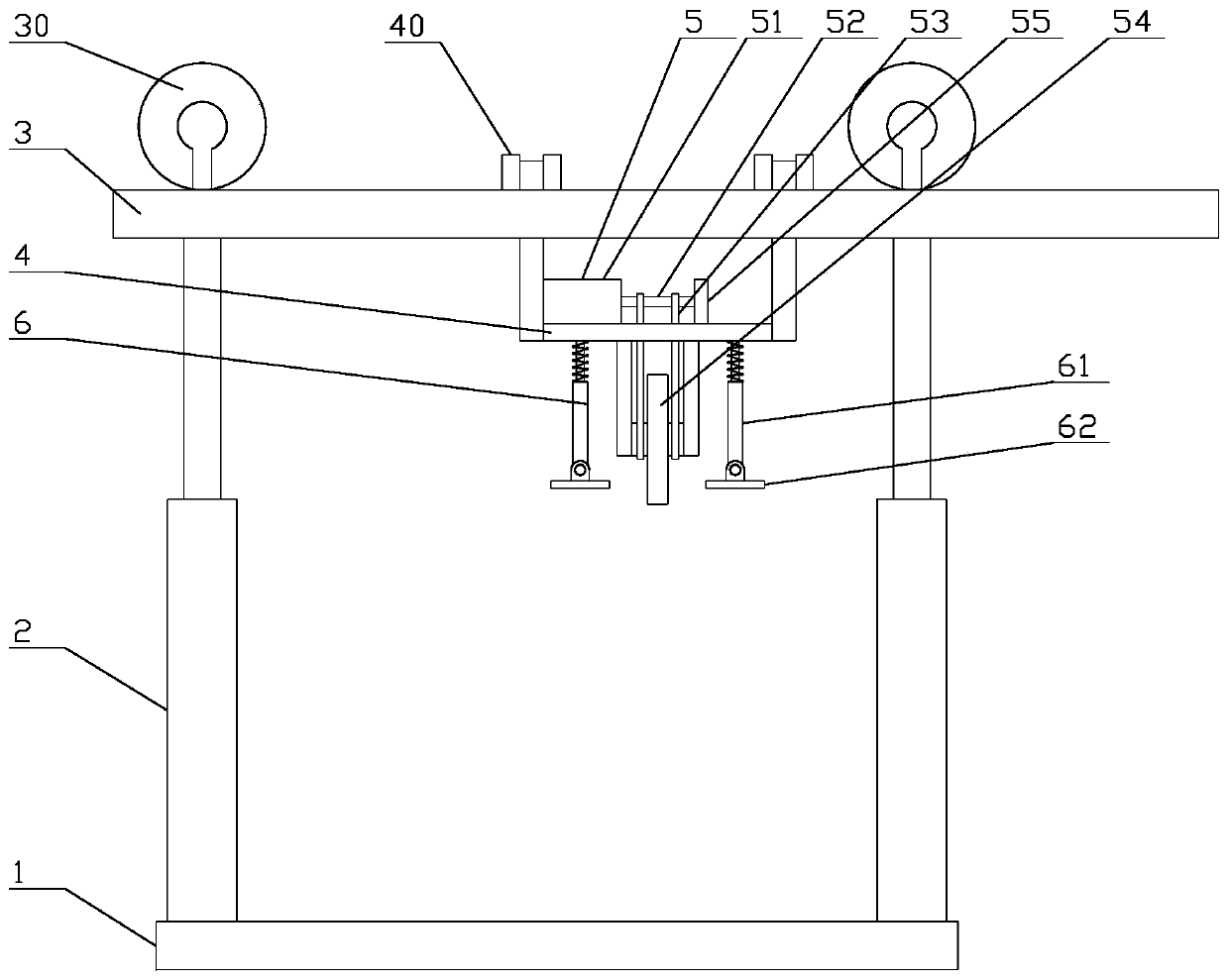

[0024] The invention is like Figure 1-5 As shown, it includes a base 1, a lifting column 2, a top plate 3, a top plate driving mechanism, a hanging plate 4, a pair of booms, a hanging plate driving mechanism, a cutting mechanism 5 and an auxiliary mechanism 6;

[0025] The top plate 3 is connected to the top of the base 1 through the lifting column 2, so that the top plate 3 reciprocates up and down under the driving of the lifting column 2;

[0026] The top of the lifting column 2 is in the shape of a stepped shaft with a small top and a large bottom. The top plate 3 is provided with a long sliding hole 1 that is adapted to the small shaft of the stepped shaft. The top plate driving mechanism includes a power source 1 And a pair of driving wheels 30, a pair of said driving wheels 30 are respectively hinged to the tops of the two lifting columns 2 and rotate under the drive of the power source 1, thereby driving the top plate 3 along the elongated sliding hole. Linear reciprocati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com