Novel intelligent environment-friendly automatic garbage recovery system

An automatic recycling and garbage technology, applied in garbage collection, trash cans, garbage receptacles, etc., can solve the problems of complex operation, unfavorable garbage recycling processing, low degree of automation, etc., to enhance safety, reduce manual operation, and facilitate operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

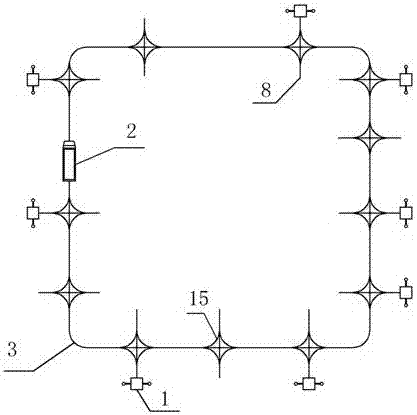

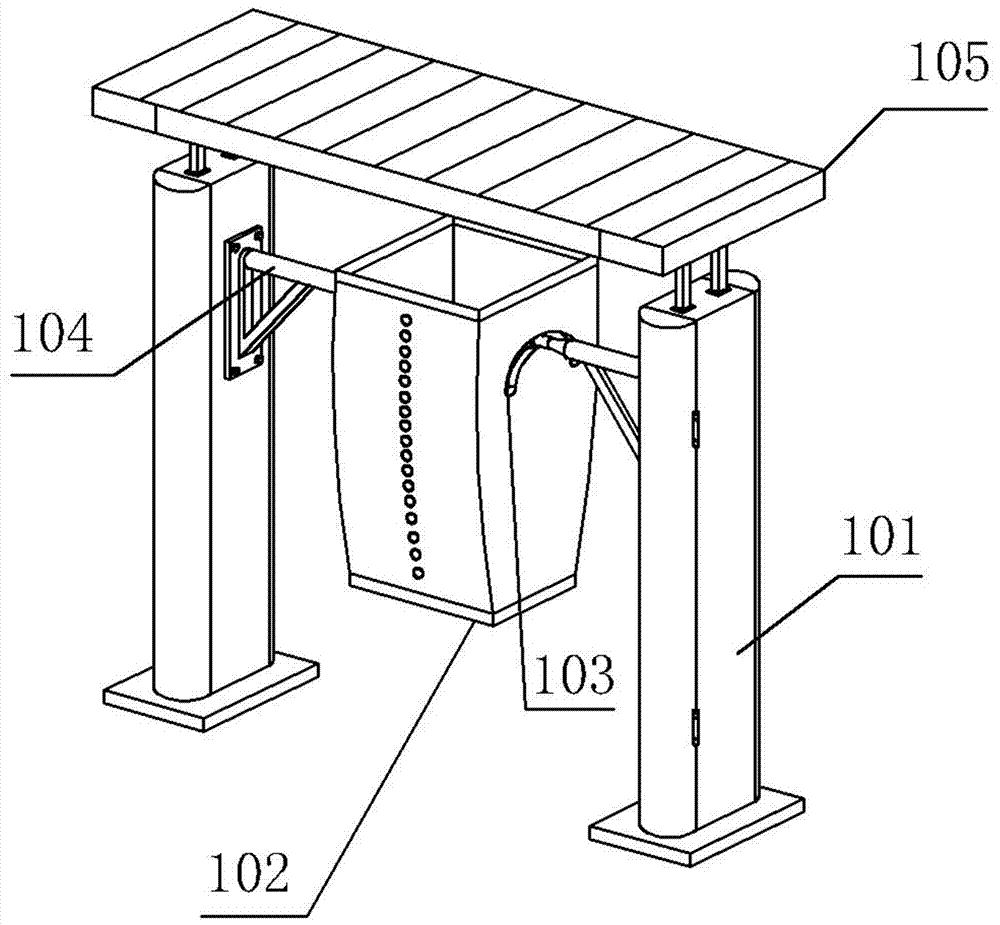

[0037] A kind of novel intelligent environment-friendly garbage automatic recycling system of the present embodiment, such as figure 1 with Figure 8 As shown, it mainly includes a single-line loop connection track 3 arranged in a certain area and a trash can 1 arranged along the track 3. The track 3 is black and has a width of 20 cm; and the trash cans 1 are evenly arranged on the track 3 on both sides. The whole system also includes a garbage truck 2 that automatically travels around the track 3, the bottom of the garbage truck 2 is provided with a line-finding sensor 9 corresponding to the track 3 to identify the track 3, and the garbage truck 2 is provided with interconnected processing processor and A wireless communication module 6, A processor 4 adopts stm32 single-chip microcomputer, and A wireless communication module 6 adopts ZigBee communication technology. The A processor 4 identifies the track 3 through the line-finding sensor 9, thereby controlling the garbage ...

Embodiment 2

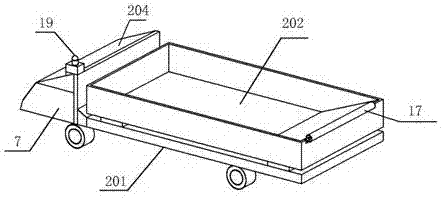

[0043]This embodiment is further defined on the basis of the above-mentioned embodiment 1, as figure 2 with Figure 5 As shown, the garbage truck 2 is now limited, and the garbage truck 2 includes a chassis 201 and a fence 202 arranged on the chassis 201; Steering gear 205, described line-finding sensor 9 is arranged on the middle part of steering wheel group 203; The other side of chassis 201 is provided with driving wheel 206 groups, and described driving wheel 206 groups comprise two driving wheels 206 driven by independent motors; A storage battery 7 box is provided on the chassis 201 close to the fence 202, and a control box 204 for placing the A processor 4, the memory 12, the positioning chip 13 and the A wireless communication module 6 is arranged on the storage battery 7 box. The steering gear 205 is a servo motor, and its steering angle is controlled by the A processor 4, because the value calculated by the PID algorithm in the A processor 4 is directly used as the...

Embodiment 3

[0046] This embodiment is further defined on the basis of the above-mentioned embodiment 2. The front and rear ends of the garbage truck 2 are provided with ultrasonic obstacle detectors 14, and the A processor 4 receives the signals from the two ultrasonic obstacle detectors 14. Feedback to judge whether there are obstacles blocking the garbage truck 2. The multi-beam ultrasonic obstacle detector 14 is an ultrasonic distance measuring device, that is, an existing vehicle body radar, which is used to monitor obstacles in front of and behind the car. Once an obstacle is detected within a certain distance in front of or behind the vehicle, the entire garbage truck 2 will brake, and at the same time send an alarm signal to the cloud server through the A wireless communication module 6, and the manager can receive the alarm signal and take timely action. Action; when the ultrasonic obstacle detector 14 does not detect an obstacle, it resumes traveling. Other parts of this embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com