Ice melting device for gate of hydropower station

A technology for hydropower stations and gates, applied in water conservancy engineering, hydraulic engineering equipment, marine engineering, etc., can solve the problems of unsatisfactory ice breaking effect, high failure rate of mechanical structure, high energy consumption, etc., to ensure safety and reliable operation and maintenance of gates. Convenient, safe and effective operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

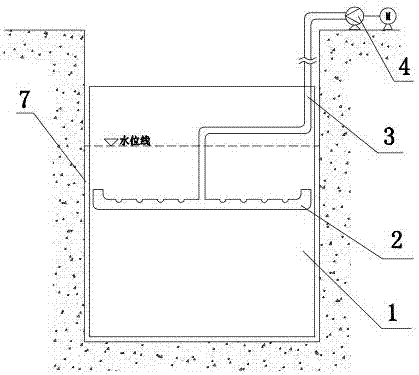

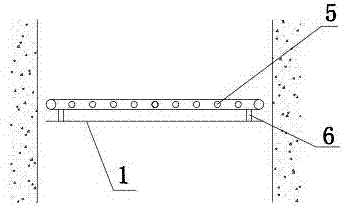

[0020] A hydropower station gate ice melting device, such as figure 1 , figure 2 As shown, the dam body of the hydropower station is provided with a water (flood discharge) door slot 7, and the door slot 7 is provided with a gate 1 that can be opened or closed. The ice-melting device includes a spray pipe 2, an air delivery pipe 3 and an air compressor 4. The spray pipe 2 is arranged on the water facing surface of the gate 1. The spray pipe 2 is arranged at the lower part of the gate 1 and is located below the water level line. The spray pipe 2 Installation method: use the hoist to operate the gate to a reasonable position, install the injection pipe 2, and the injection pipe 2 is provided with an air injection hole 5. The injection pipe 2 is connected with the air compressor 4 through the air delivery pipe, and the air compressor 4 is connected with the motor.

[0021] The air delivery pipe 3 is a flexible pipe, and the jet holes 5 are evenly distributed on the jet pipe 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com