A kind of three-dimensional layered niznal semiconductor multi-metal oxide composite material and its preparation method and application

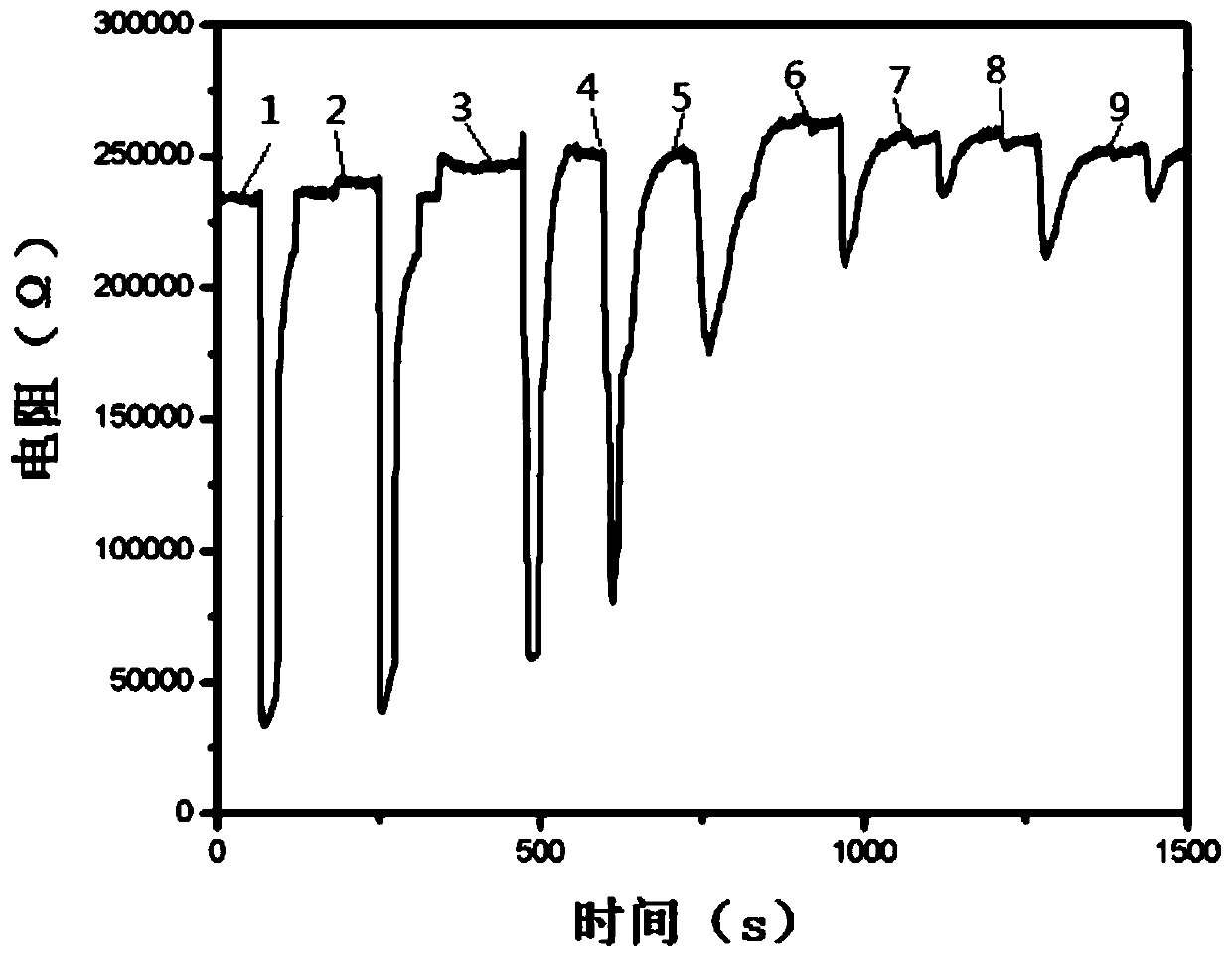

A multi-metal oxide and composite material technology, which is applied in the field of three-dimensional layered NiZnAl semiconductor multi-metal oxide composite materials and its preparation and application, can solve the problems of poor selectivity, high cost, low sensitivity, etc. The preparation method is simple and the effect of improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

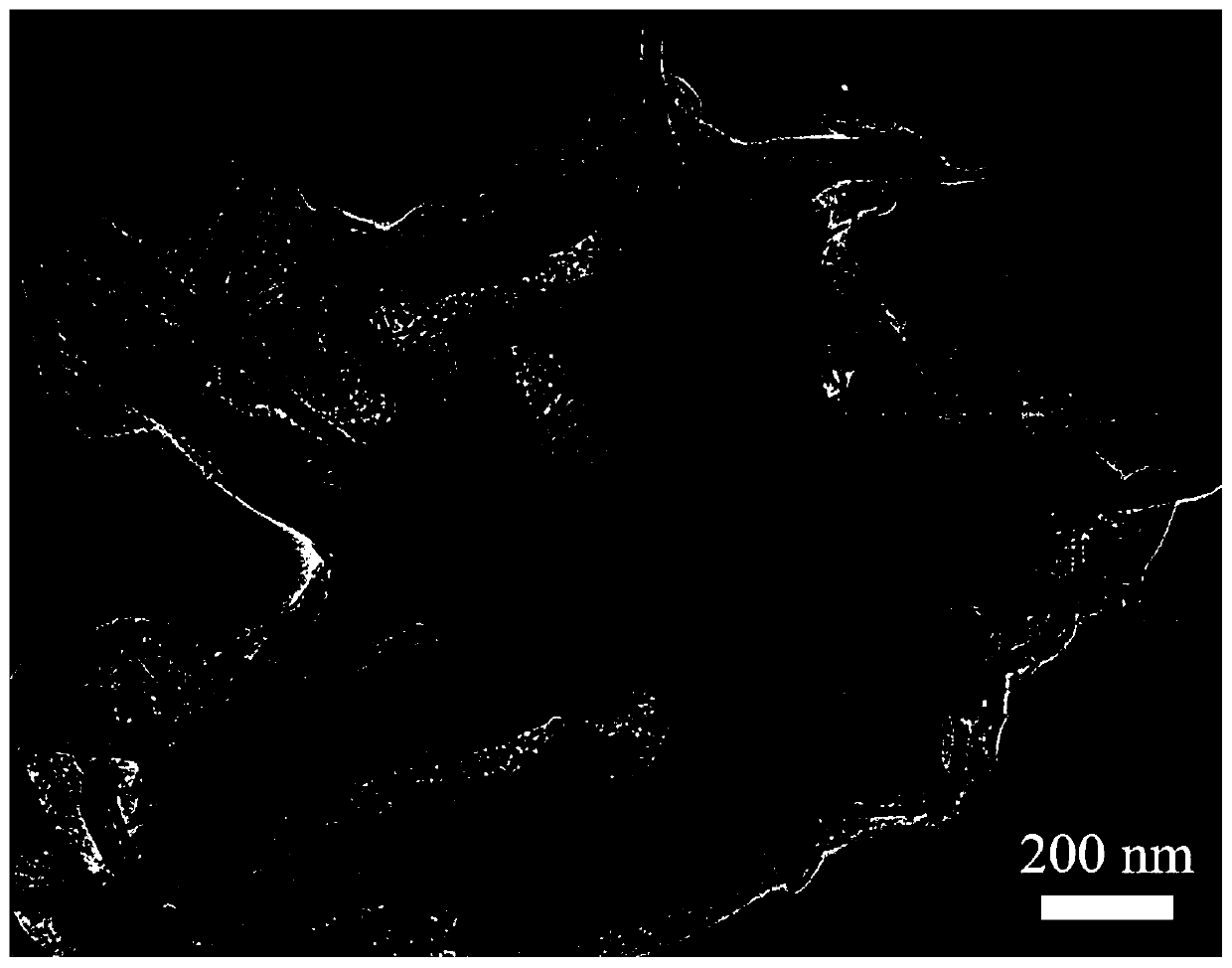

[0033] Embodiment 1: In this embodiment, the three-dimensional layered NiZnAl semiconductor multi-metal oxide composite material is made of nickel nitrate, aluminum nitrate, zinc nitrate, surfactant and precipitant;

[0034] The surfactant is sodium lauryl sulfate; the precipitant is an aqueous urea solution, and the concentration of the aqueous urea solution is 0.001 to 1mol / L;

[0035] The mol ratio of described nickel nitrate, zinc nitrate and aluminum nitrate is 2:(3~5):(2~4); The mol ratio of described aluminum nitrate and surfactant is 2:(2~4); The molar ratio of aluminum nitrate to precipitation agent is 1: (8.9-9.9).

[0036] This embodiment has the following beneficial effects:

[0037] 1. In the preparation process of the three-dimensional layered NiZnAl semiconductor multi-metal oxide composite material in this embodiment, the surfactant is used as the template agent and the intercalation anion, thereby realizing the control of the sample morphology and interlayer ...

specific Embodiment approach 2

[0042] Specific embodiment two: the preparation method of the three-dimensional layered NiZnAl semiconductor multi-metal oxide composite material of the present embodiment is carried out according to the following steps:

[0043] 1. Weigh nickel nitrate, aluminum nitrate, zinc nitrate, surfactant and precipitant as raw materials, add the weighed raw materials into a beaker filled with deionized water, perform ultrasonic treatment for 5-10 minutes, and then stir for 20-30 minutes , to obtain a mixed solution; the mass of the raw material taken by weighing and the volume ratio of deionized water are 0.8g:(35~45)mL;

[0044] 2. Pour the mixed solution obtained in step 1 into a stainless steel autoclave, heat the stainless steel autoclave in a water bath at 120 to 200 ° C for 4 to 20 hours, and then cool the stainless steel autoclave to room temperature;

[0045] 3. Filter the solution obtained in the stainless steel autoclave in step 2 to obtain a precipitate, remove impurities a...

specific Embodiment approach 3

[0053] Specific embodiment three: this embodiment is different from specific embodiment two in that: the mol ratio of nickel nitrate, zinc nitrate and aluminum nitrate described in step one is 2:(3~5):(2~4); The molar ratio of aluminum to the surfactant is 2: (2-4); the molar ratio of the aluminum nitrate to the precipitation agent is 1: (8.9-9.9). Other steps and parameters are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com