Adhered slag partition device for molten iron tank and preparation method

A technology for molten iron tanks and partitions is applied in the directions of manufacturing tools, casting equipment, metal processing equipment, etc., which can solve the problems of reducing the preparation cost of castables, being easily damaged, and being difficult to popularize and apply, so as to avoid the floating and loosening of the slag breaker. Ensuring continuous stability, optimized structure and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

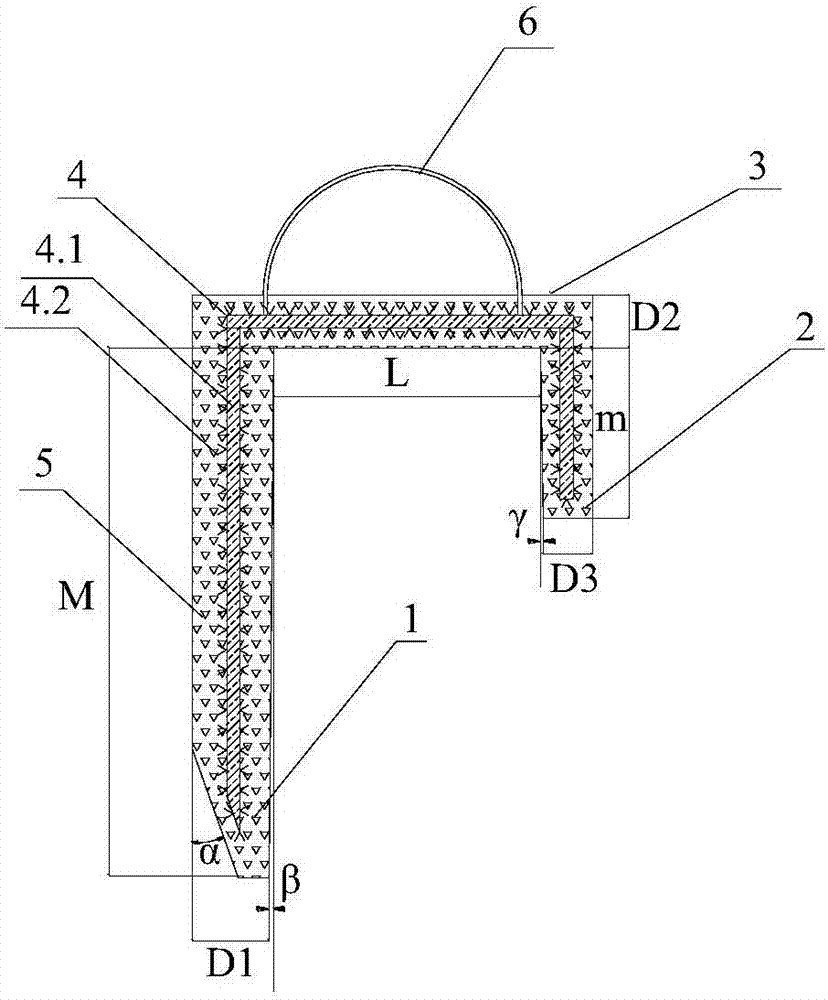

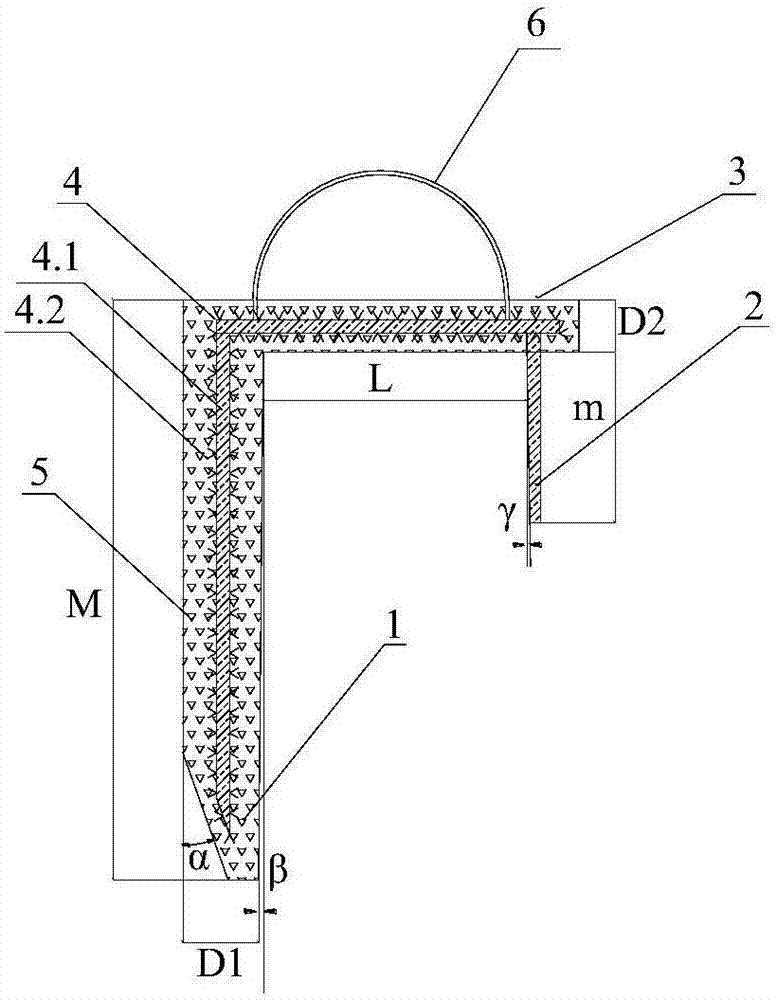

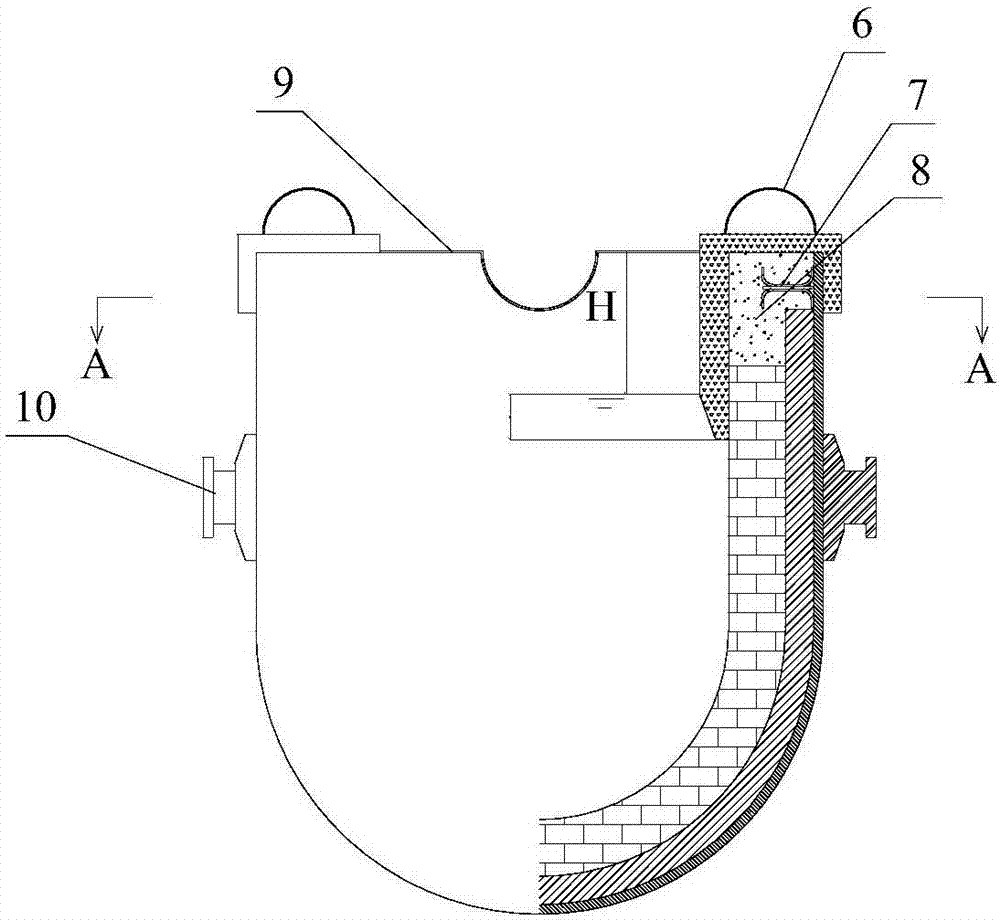

[0036] like figure 1 The sticky slag breaker for the ladle includes a beam 3, a long leg 1 vertically connected to one end of the beam 3, and a short leg 2 vertically connected to the other end of the beam 3, forming a π-shaped breaker. The beam 3, the long leg 1 and the short leg 2 are all composed of a steel core component 4 wrapped by a refractory castable lining 5, and the steel core component 4 is composed of threaded steel bars or steel pipes or flat steel 4.1 welded with a V-shaped metal anchor 4.2; of course, The long leg 1, the crossbeam 3 and the short leg 2 can all be directly formed by the steel core assembly 4. When the short leg 2 is directly formed by the steel core assembly 4, the steel core assembly 4 of the short leg 2 is not welded with the V-shaped metal anchor piece 5, like figure 2 shown. Through the structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com