Single-motor-driven multi-gripper mechanism suitable for any gripper position

A single-motor-driven, hand-positioned technology, used in manipulators, chucks, manufacturing tools, etc., can solve the problems of restricting the overall mechanism performance, high cost, large volume and weight, etc., to improve material grasping performance, improve performance, reduce The effect of volumetric weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

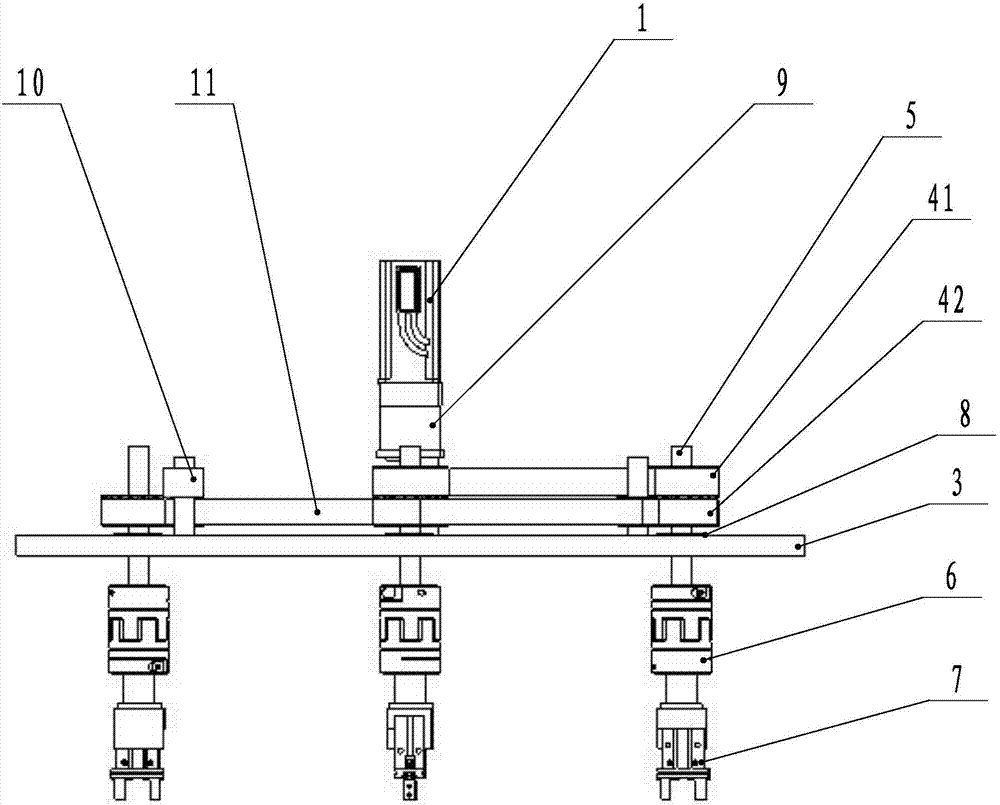

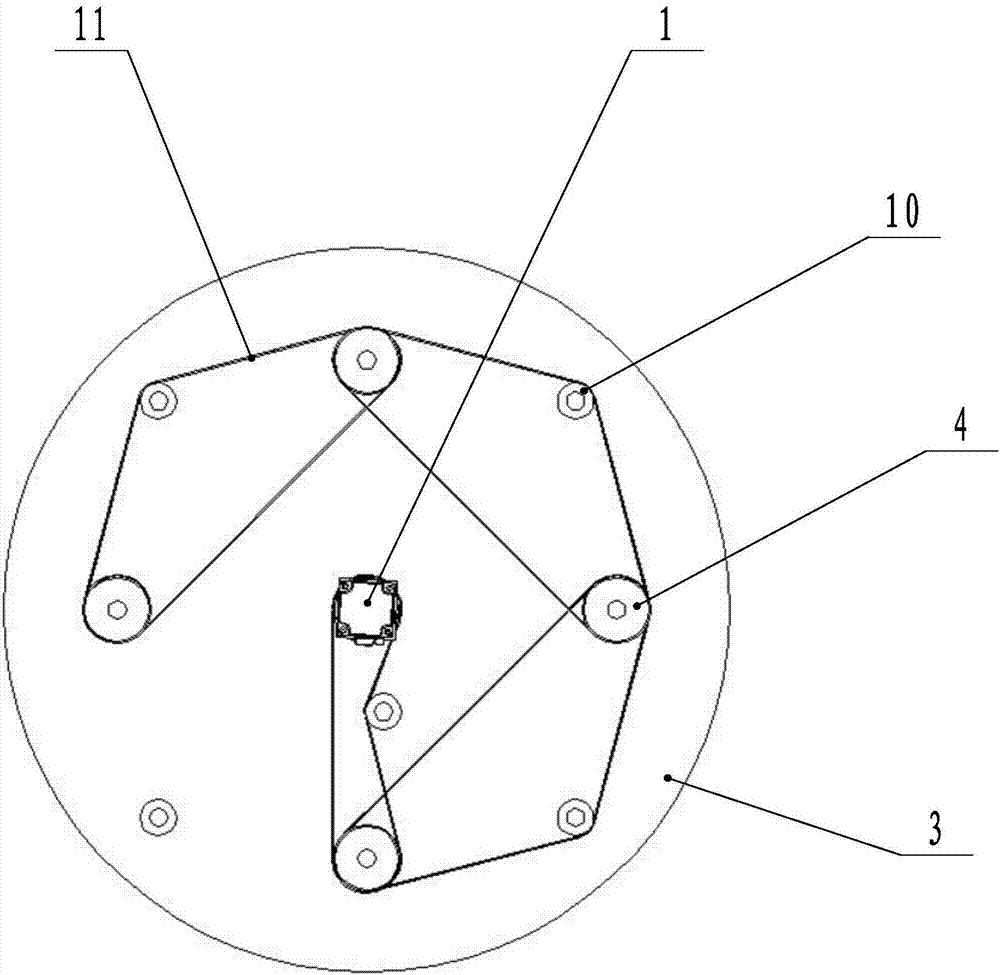

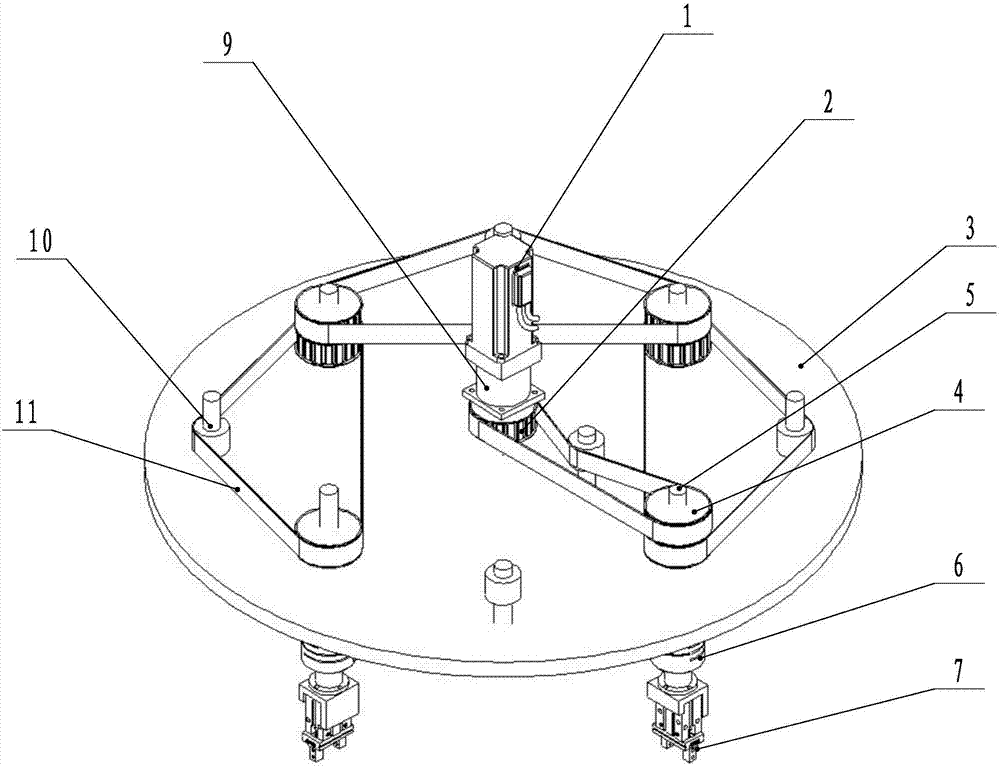

[0018] refer to Figure 1 to Figure 4 , a single-motor-driven multi-grip mechanism adapted to any gripper position of the present invention is installed on the XY plane motion mechanism, so that its motion in the XY position can be realized through the XY plane motion mechanism. Specifically, this The invention includes a fixed frame and a plurality of gripper mechanisms 7. The present invention can be installed on the XY plane motion mechanism through the fixed frame, and can also be installed in other ways. The drive motor 1 for teaching the rotational position of the mechanism 7, the output shaft of the drive motor 1 is drivingly connected with the driving pulley 2, and the driving pulley 2 is connected with the driven pulley 4 through the synchronous belt 11, and the driven belt The pulley 4 can be connected to the driven pulley 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com