Oil-containing sludge self-heat-supply anaerobic pyrolysis equipment, and pyrolysis method thereof

A self-heating and pyrolysis technology, used in pyrolysis treatment of sludge, petroleum industry, special forms of dry distillation, etc., can solve the problem of oily sludge treatment equipment not being energy-efficient, and can solve the problem of sticking to the wall and reduce the moisture content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

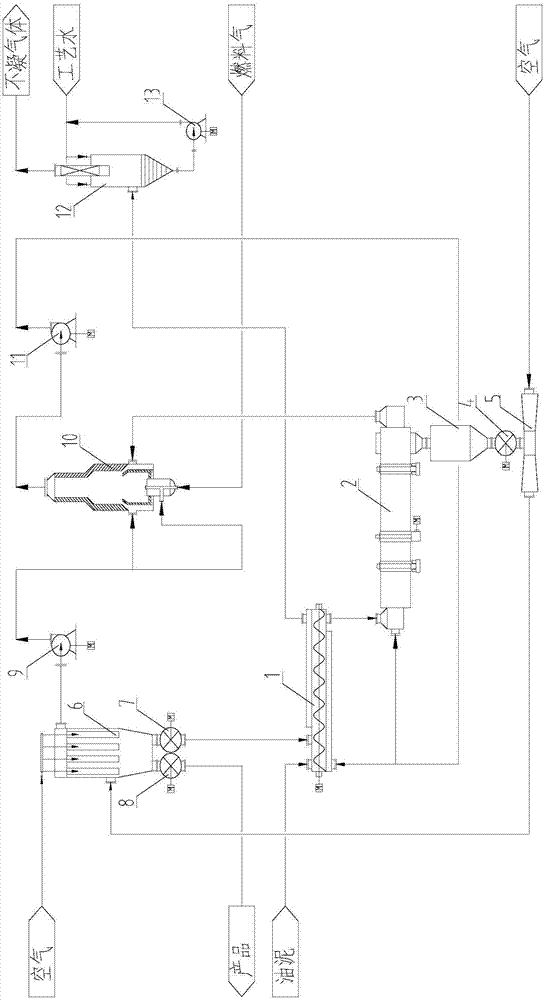

[0031] A self-heating anaerobic pyrolysis equipment for oily sludge, including a mixing conveyor 1 for inputting oily wet sludge and oil residue, the outlet below the mixing conveyor 1 is connected to a rotary pyrolysis furnace 2, and the rotary The outlet above the rotary pyrolysis furnace 2 is connected to a direct-fired incinerator 10, the fuel gas pipeline is connected to the bottom of the direct-fired incinerator 10, the outlet below the rotary pyrolysis furnace 2 is connected to a sealed buffer bin 3, and the outlets of the sealed buffer bin 3 are in turn The rotary unloader 4 and the Venturi conveyor 5 are connected, the outlet of the Venturi conveyor 5 is connected to the bag filter 6, the Venturi conveyor 5 is connected to the air intake channel, and the first rotary is connected under the bag filter 6. The unloader 8 and the second rotary unloader 7, the air intake channel is connected above the bag filter 6, the first rotary unloader 8 is connected to the product out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com