Microwave-based moving blade tip clearance and vibration parameter fusion measurement device

A technology of blade tip clearance and vibration parameters, applied in measuring devices, measuring ultrasonic/sonic/infrasonic waves, using wave/particle radiation, etc., can solve the problems that the capacitive method cannot be satisfied, and the measurement accuracy of the optical method is easily affected by oil pollution and other problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

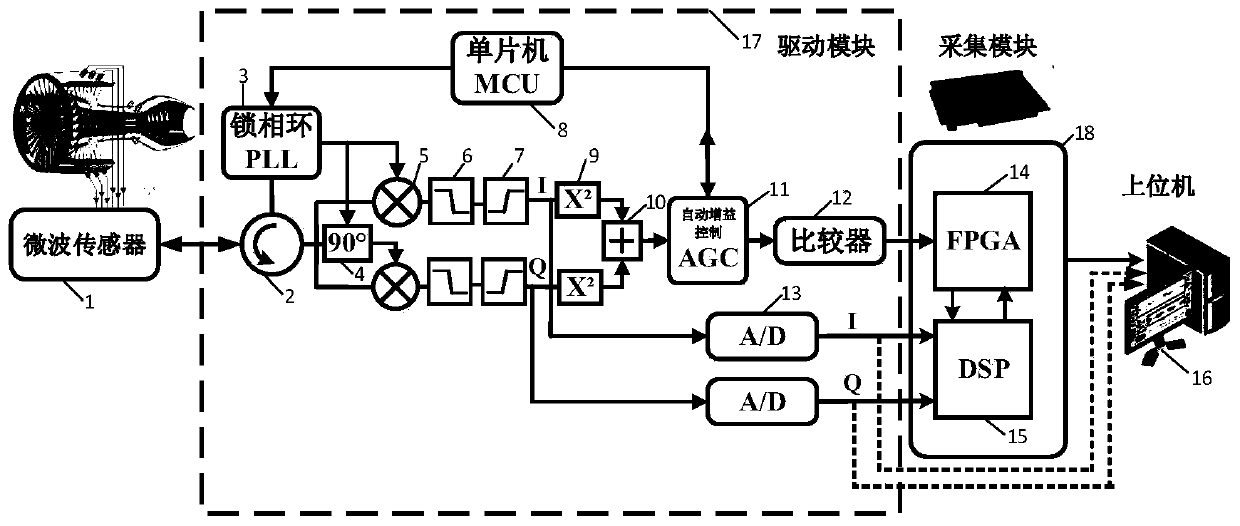

[0080] (1) In the present invention, the sensor adopts a microwave sensor to utilize the advantages of microwave sensor high temperature resistance, good reliability, wide dynamic range, insensitivity to medium, ability to measure non-metallic blades, and ability to measure in a multi-pollutant environment to realize High-speed fusion measurement of moving blade tip clearance and timing parameters under high temperature and severe working conditions.

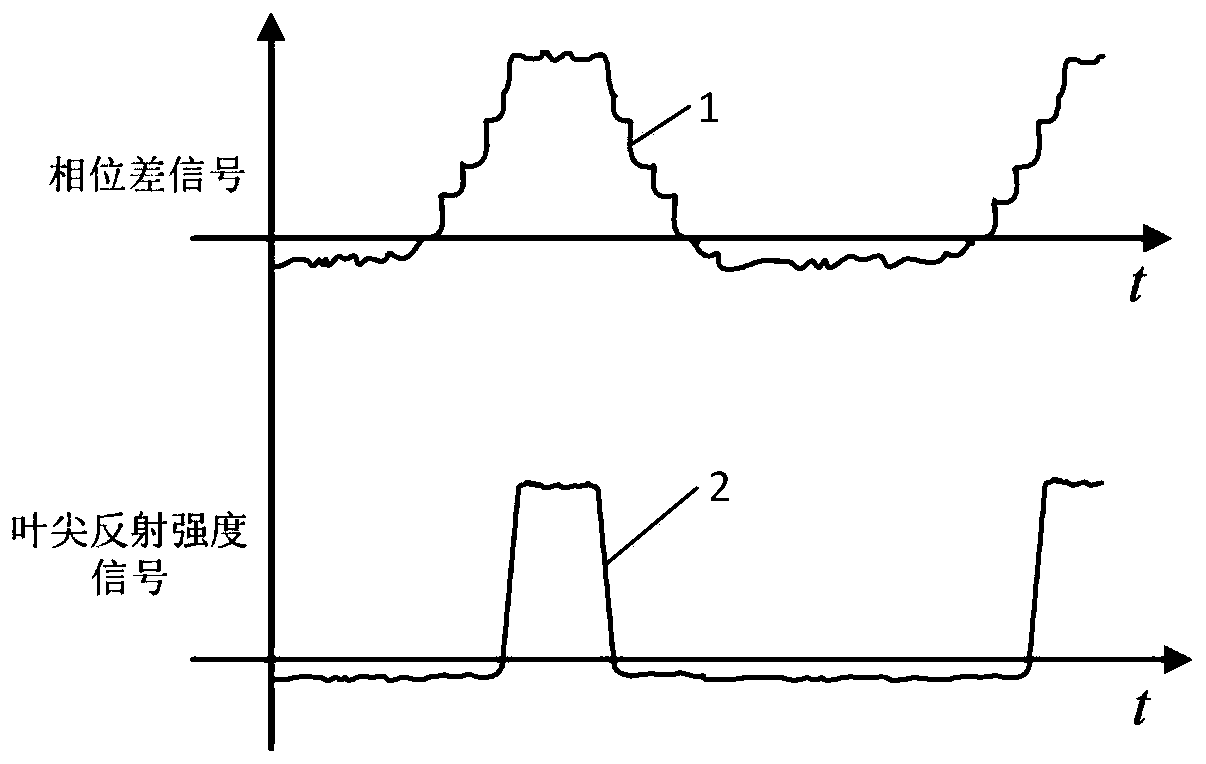

[0081] (2) The present invention provides a general displacement measurement method based on the principle of microwave phase ranging to realize the measurement of the tip clearance of the moving blade, and the displacement measurement method can be generally used for transients within the half-wavelength range of the microwave near-field region Measurement of displacement value; the method for measuring transient displacement value proposed by the present invention can realize high-precision measurement of blade tip clearance. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com