A method for judging the deterioration of tobacco spices

A technology of tobacco flavor and methanol solution, which is applied in material separation, analysis materials, instruments, etc., can solve problems such as loss of production enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

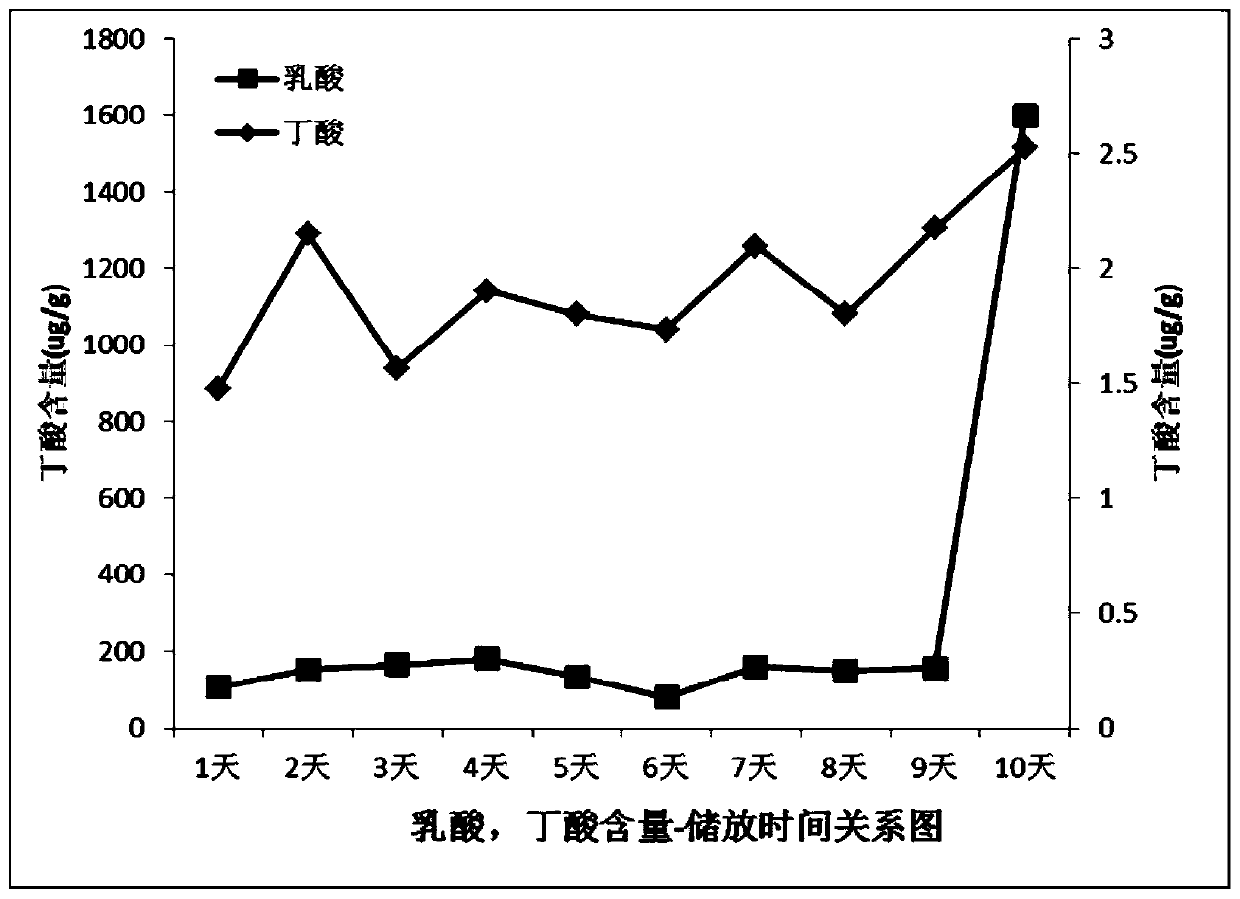

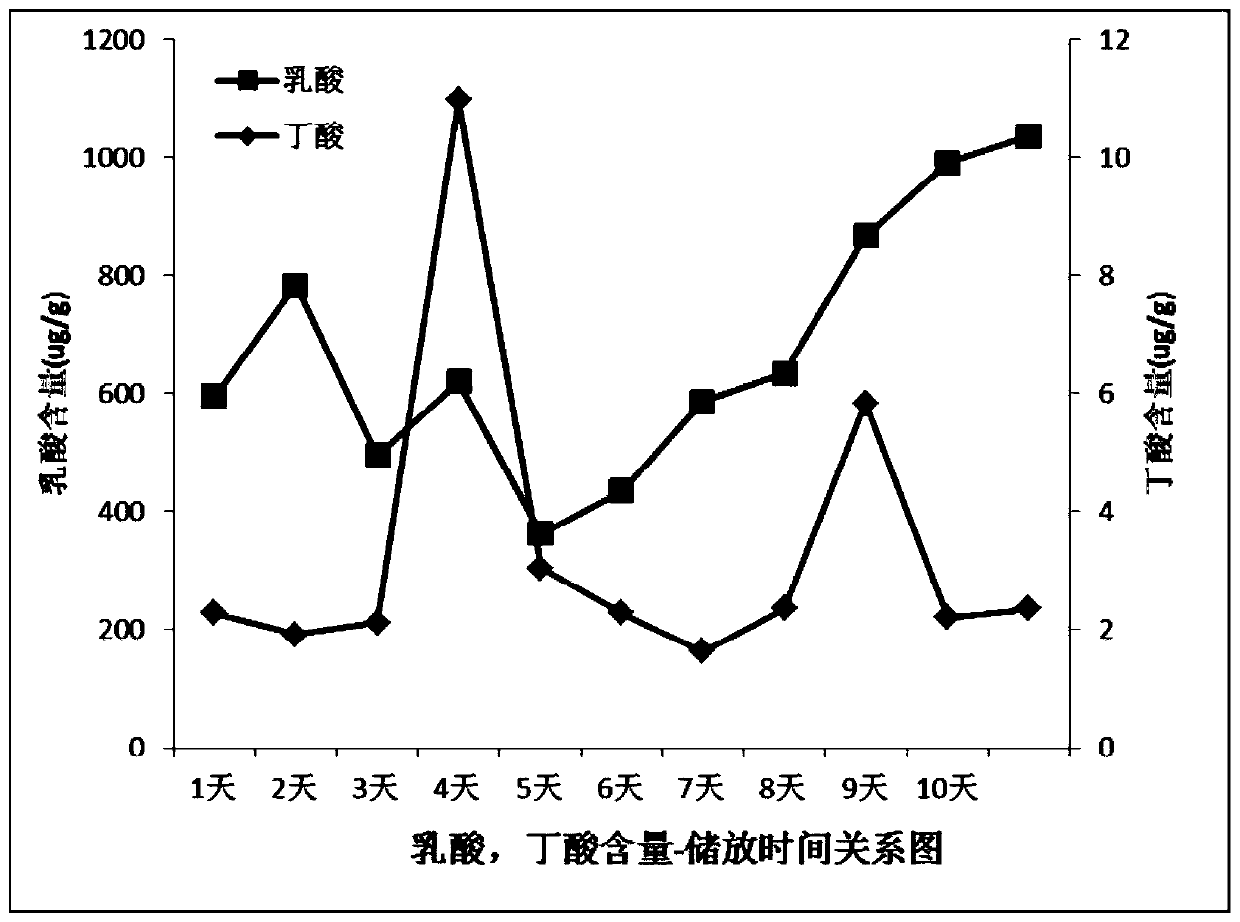

[0021] 1. Determination of tobacco flavors before and after storage

[0022] The contents of lactic acid and butyric acid in 6 tobacco flavor samples before and after storage were investigated, and determined by comparing the contents.

[0023] 1) Sample pretreatment

[0024] Accurately weigh 1g of tobacco flavoring respectively, adjust the pH of the flavoring with 0.1mol / L sodium hydroxide-methanol solution, and adjust the pH value to 8-9, and then put the moisture and Evaporate the solvent to dryness; redissolve the residue of the evaporated solvent and water with 5% sulfuric acid-methanol solution (V / V), take 1mL of the redissolved sample solution and place it in a glass bottle, and seal it in a water bath at 70°C. reaction, the reaction time is 30min; after the reaction is completed, the reaction solution is cooled to room temperature, and 5mL of n-hexane is added for vibration extraction. spectrum analysis.

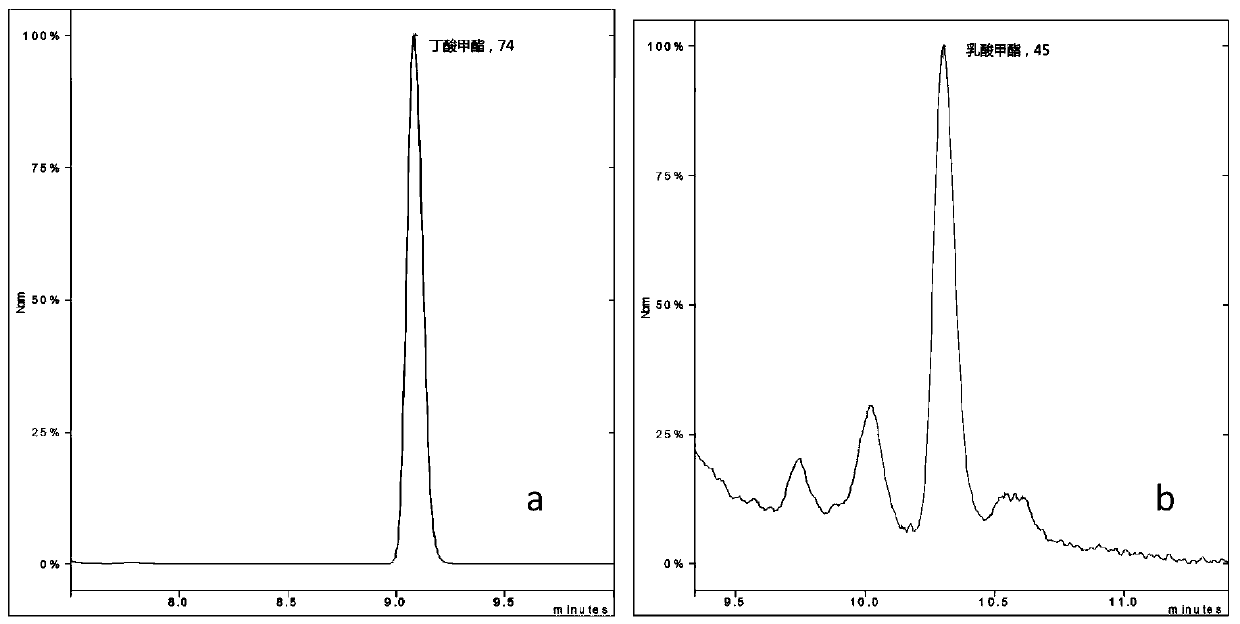

[0025] 2) Analysis by gas chromatography-mass spectrometry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com