A catamaran model towing test device

A test device, catamaran technology, applied in the field of catamaran model towing test device, can solve the problems of complex hull structure, sensitive weight distribution, etc., and achieve the effects of high test accuracy, simple debugging, and convenient use and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

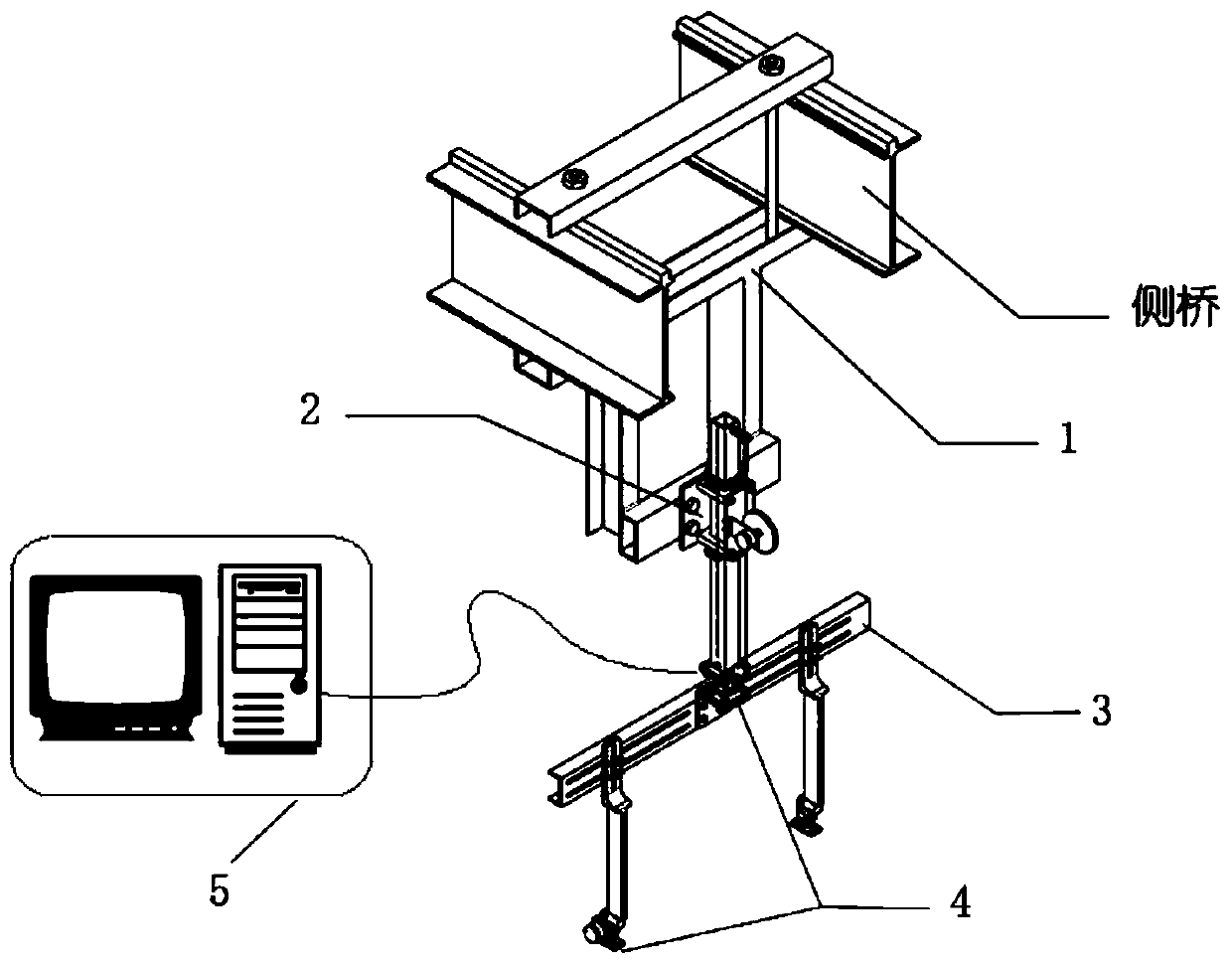

[0049] Such as figure 1 As shown, the present invention includes a fixed connection mechanism body 1, a heave transmission system 2, a sheet positioning mechanism 3, a signal measurement system 4, and a data acquisition and recording system 5.

[0050] The fixed connection mechanism body 1 is tightly fixed on the trailer side bridge, the heave transmission system 2 is fixed on the fixed frame 6 of the fixed connection mechanism body 2, and the upper end of the sheet positioning mechanism 3 is connected with the heave transmission system 2, The lower end is connected to the sheet body of the catamaran model through the connecting plate 32 in the signal measurement system 4, and the heave, trim angle and load cell in the signal measurement system 4 are connected to the respective measurement and sensing units through bolts, etc., and the data The acquisition and recording system 5 is mainly used for powering the sensors in front and converting the analog electrical signals trans...

Embodiment 2

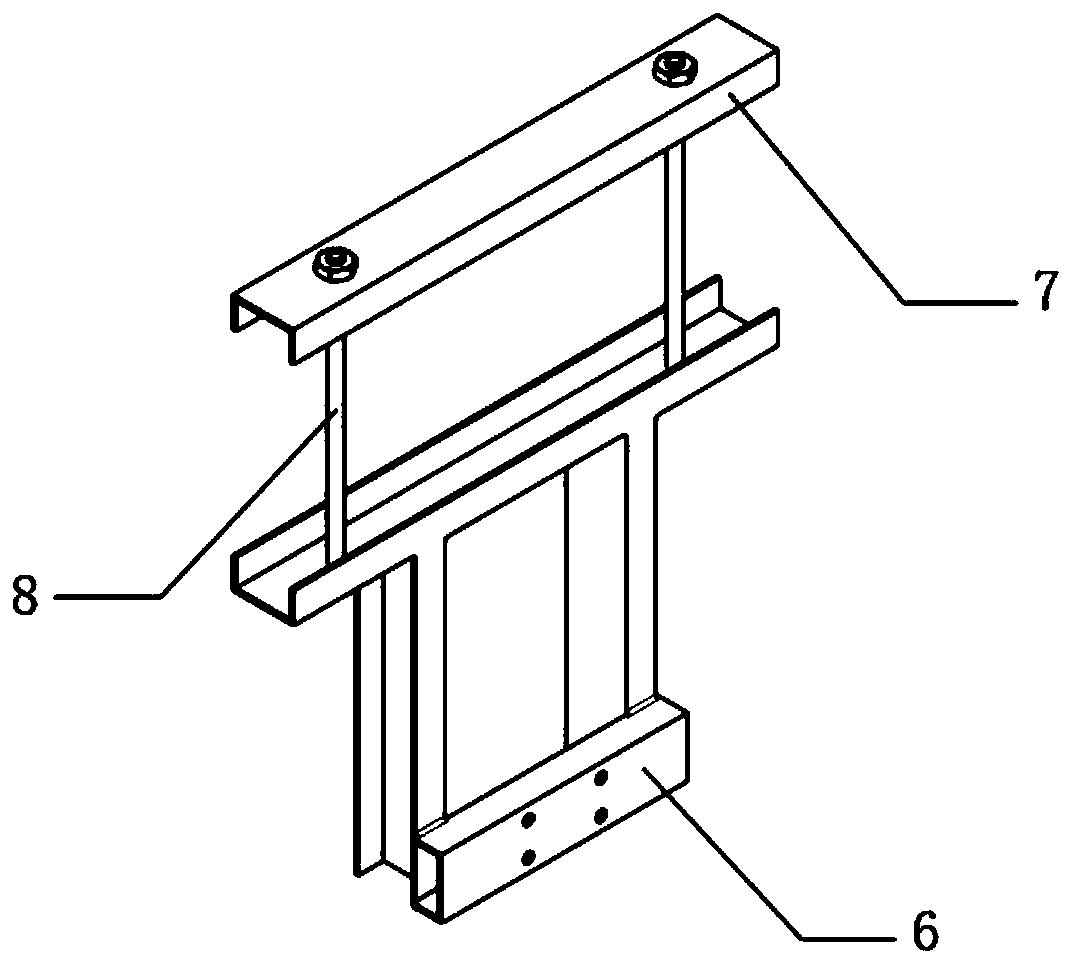

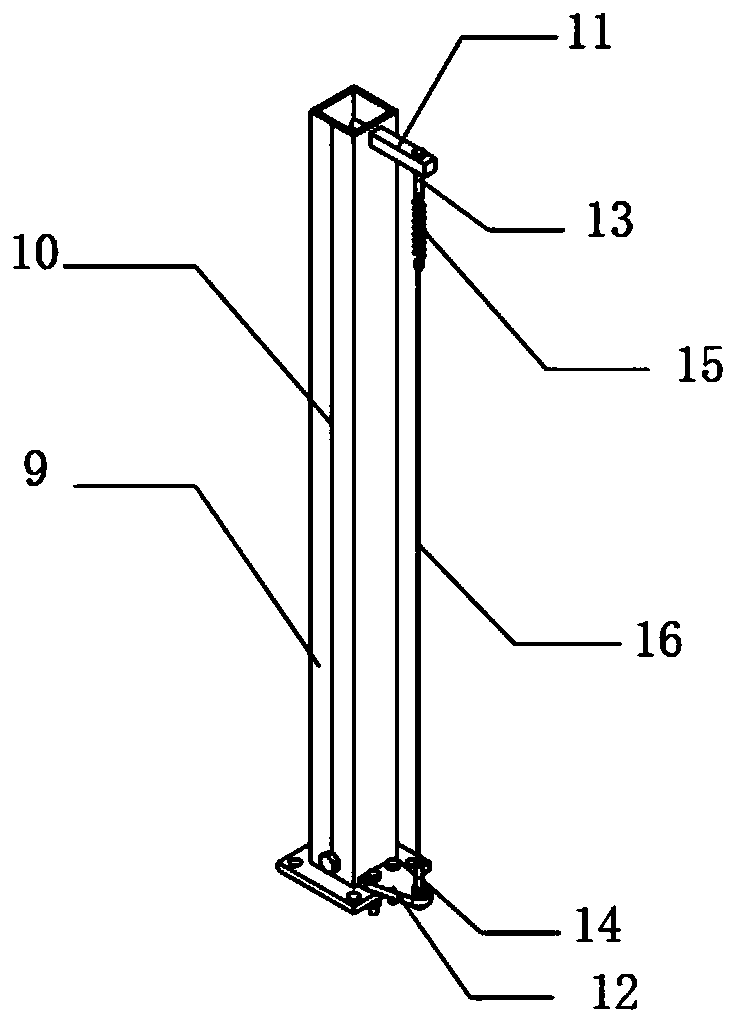

[0057] Such as Figure 9 As shown, it is a schematic diagram when the present invention is installed on an ordinary catamaran for a test. Before the test starts, firstly, the upper end of the present invention is tightly fixed on the trailer side through the connecting beam 7, the set screw 8, the nut, etc. in the fastening mechanism body 1. Above the bridge, the lower end is connected with the connecting plate on the catamaran through the fixed support 32 in the signal measurement system 4 . Then by adjusting the sheet positioning mechanism 3, the sheet spacing and height of the catamaran model are accurately regulated. During the test, the test data of the ship model such as heave, trim, and resistance are converted into electrical signals by the load cell, heave, and trim sensors in the signal measurement system 4, and then transmitted to the data acquisition and recording system 5 , the data acquisition and recording system 5 converts the analog electrical signal transmit...

Embodiment 3

[0059] Such as Figure 10 As shown, it is a schematic diagram of the present invention installed on a small waterplane catamaran for the test. Before the test starts, the upper end of the present invention is first tightly fixed by the connecting beam 7, the set screw 8, the nut, etc. in the fastening mechanism body 1. On the trailer bridge, the lower end is connected with the connecting plate on the catamaran through the fixed support 32 in the signal measurement system 4 . What is different from ordinary catamarans is that the small waterplane catamaran needs to obliquely penetrate the arm of the sheet body positioning mechanism 3 into the cabin of the small waterplane catamaran. Conditions require adjustments. During the test, the test data of the ship model such as heave, trim, and resistance are converted into electrical signals by the load cell, heave, and trim sensors in the signal measurement system 4, and then transmitted to the data acquisition and recording system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com