High-power-to-weight-ratio integrated electromechanical servo actuation device

An electromechanical servo and actuating device technology, applied in the direction of electromechanical devices, transmission devices, electric components, etc., can solve the problems of low carrying capacity, low integration, small power-to-weight ratio, etc., achieve high space utilization and improve control Accuracy and the effect of improving the power-to-weight ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

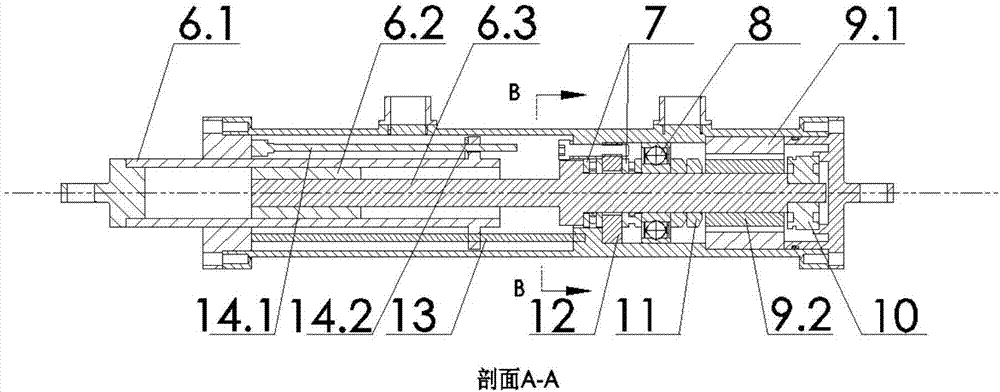

[0027] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0028] The purpose of the present invention is to overcome the deficiencies in the prior art and provide a high power-to-weight ratio integrated electromechanical servo actuator with high power-to-weight ratio, strong bearing capacity and small installation space.

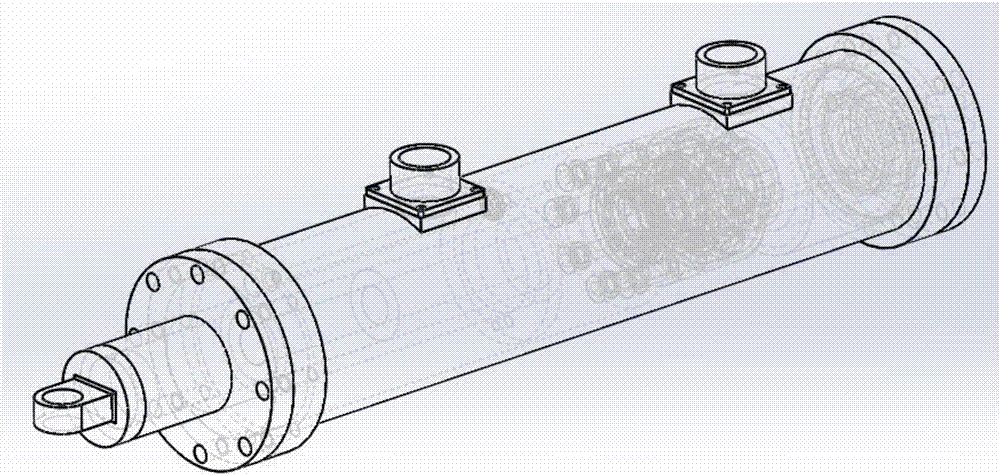

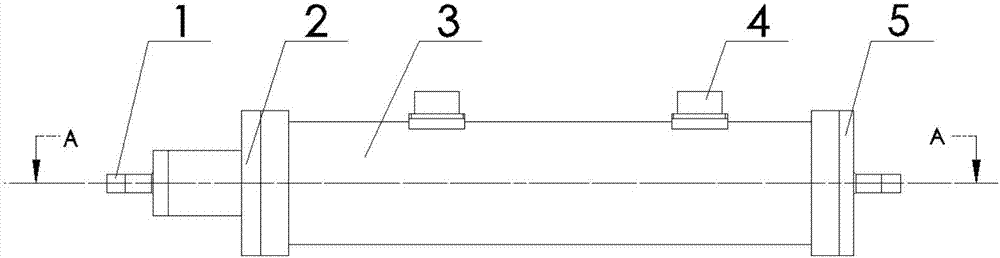

[0029] refer to figure 1 , 2 , 3, a high power-to-weight ratio integrated electromechanical servo actuator, comprising: front cover (1); front shell (2); main shell (3); aviation plug (4); rear shell (5 ); Nut (6.1); Roller assembly (6.2); Lead screw (6.3); Thrust roller bearing (7); Cylindrical roller bearing (8); Motor stator (9.1); Magnetic patch (9.2); Rotation type encoder (10); loosening nut (11); flange (12); guide rod (13); linear displacement sensor body (14.1); magnetic ring (14.2); connecting screw (15).

[0030] The joint bearing on the rear housing (5) is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com