Delayed breaker for viscoelastic surfactant-based fluids

A working medium and heat cycle technology, applied in irreversible cycle compression machines, heat exchange materials, lighting and heating equipment, etc., can solve problems such as GWP increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

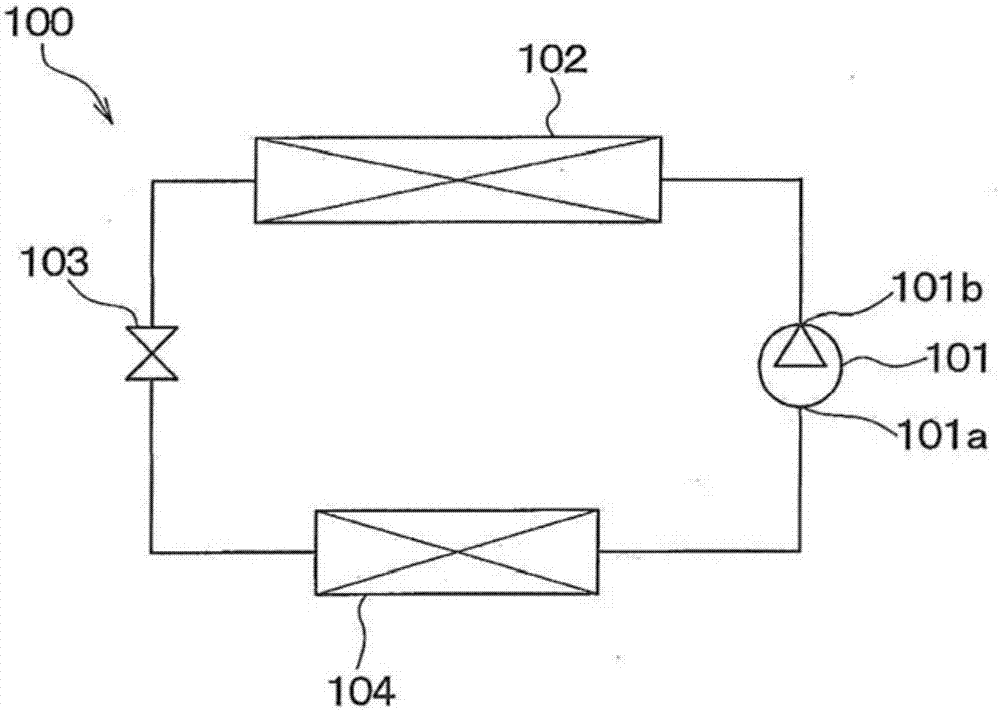

[0032] In this embodiment, an example in which the working medium of the present invention is applied to a refrigerant of a vapor compression refrigeration cycle device used in a vehicle air conditioner will be described.

[0033] Such as figure 1 As shown, the refrigeration cycle apparatus 100 of this embodiment includes a compressor 101, a condenser 102, an expansion valve 103, an evaporator 104, and the like. The compressor 101, the condenser 102, the expansion valve 103, and the evaporator 104 are sequentially connected via piping.

[0034] The compressor 101 is a device having a refrigerant suction port 101a and a refrigerant discharge port 101b, compresses the refrigerant sucked from the refrigerant suction port 101a, and discharges the compressed refrigerant from the refrigerant discharge port 101b. The condenser 102 is a radiator that radiates heat and condenses the gas-phase refrigerant discharged from the compressor 101 by exchanging heat with the air outside the ve...

Embodiment 1

[0108] The GWP of the refrigerant of Example 1 is about 150, and satisfies GWP150 or less.

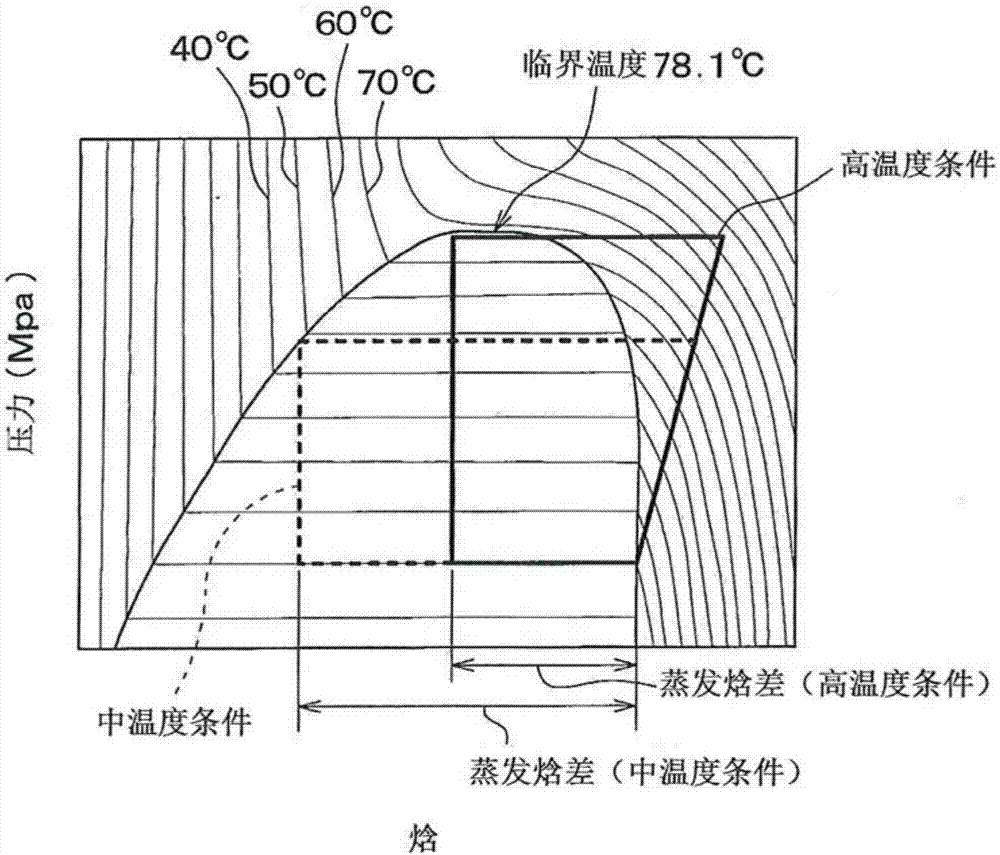

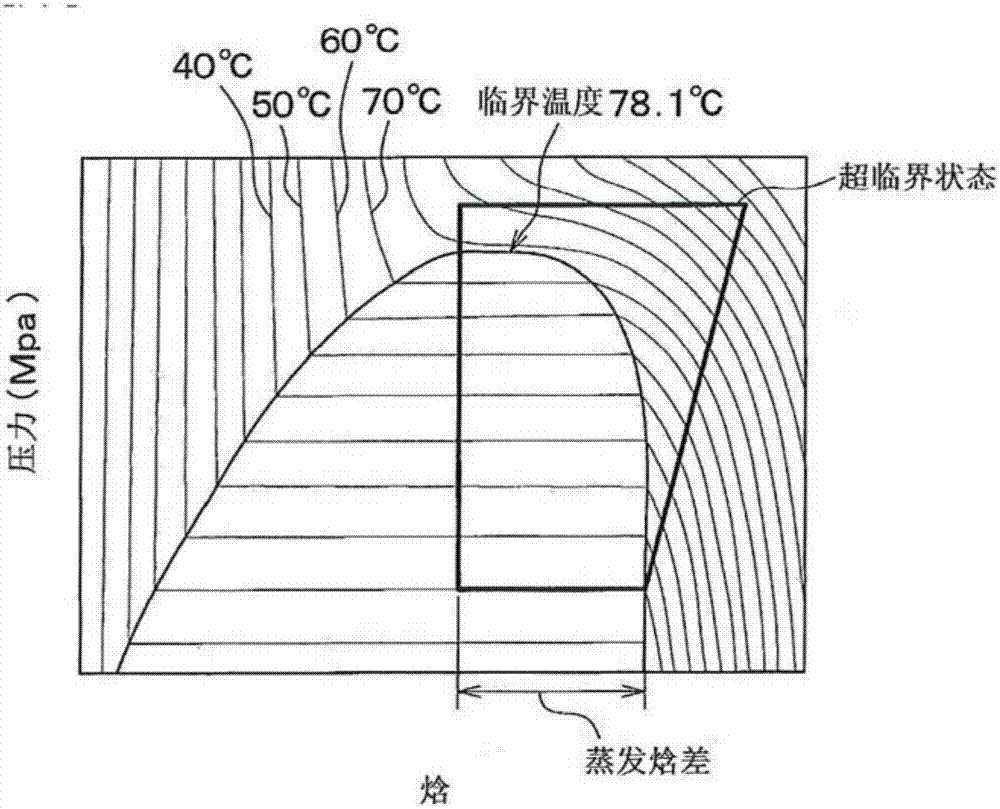

[0109] (2) Critical temperature

[0110] As described above, it is preferable that the refrigerant for vehicles can keep the condensation temperature of the refrigerant below the critical temperature even in regions where the temperature is extremely high, such as the Middle East and the Near East. When the outside air temperature is 50°C, the condensation temperature is 75 to 85°C. Therefore, the critical temperature of the refrigerant is preferably 85° C. or higher.

[0111] The critical temperature value of the refrigerant in Example 1 is about 86°C, which satisfies the target of 85°C or higher.

[0112] (3) Flammability

[0113] The refrigerant of Example 1 is compared with the mixed refrigerant of HFO-1123 and HFC-32 whose mass ratio of HFO-1123 and HFC-32 is HFO-1123:HFC-32=6:4, HFC- Less 32, more HFO-1234ze(E). Therefore, the combustibility of the refrigerant of Example 1 w...

no. 2 approach

[0124] The refrigerant of this embodiment contains HFO-1234yf (2,3,3,3-tetrafluoro-1-propene) in addition to the three components of the refrigerant of the first embodiment. That is, the refrigerant of the present embodiment is mixed with four components of HFO-1123, HFC-32, HFO-1234ze, and HFO-1234yf as main components.

[0125] As shown in Table 1, HFO-1234yf has a GWP of 1, which is very low compared to 675 of HFC-32. Furthermore, the critical temperature of HFO-1234yf is 94.7°C, which is very high compared to 59.2°C of HFO-1123 and 78.1°C of HFC-32. Also, the burning rate of HFO-1234yf is lower than that of HFC-32.

[0126] Therefore, even with the refrigerant of the present embodiment, the same effects as those of the refrigerant of the first embodiment can be obtained with respect to GWP, critical temperature, and combustibility.

[0127] Also, the GWP value of HFO-1234yf is the same as that of HFO-1234ze. Therefore, similarly to the first embodiment, in the refrigera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical temperature | aaaaa | aaaaa |

| critical temperature | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com