Steel plate for bottle cap, manufacturing method thereof, and bottle cap

A manufacturing method and bottle cap technology, which are applied in the directions of manufacturing tools, bottle/container caps, and tightly capping containers with caps, can solve problems such as reduced formability and poor bottle sealing, and achieve the effect of thinning walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

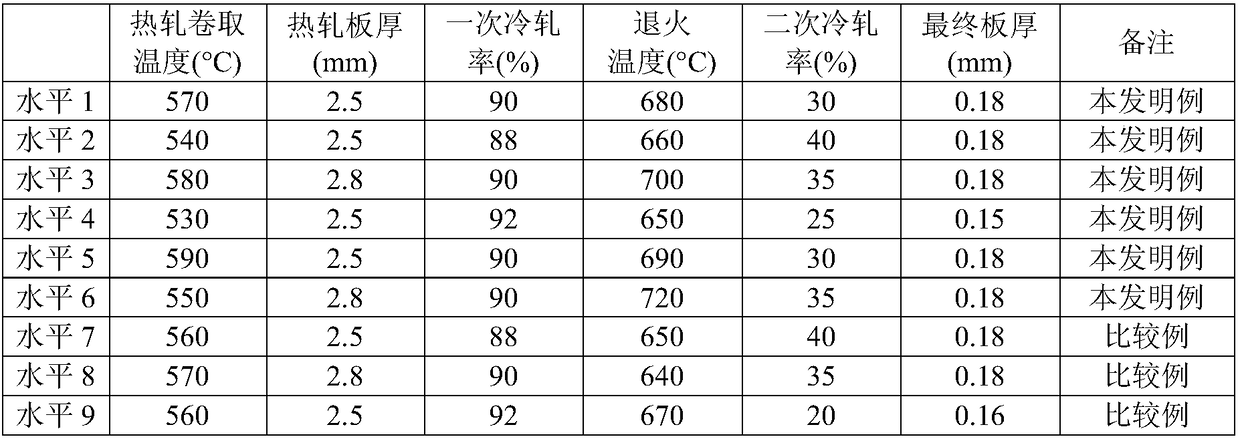

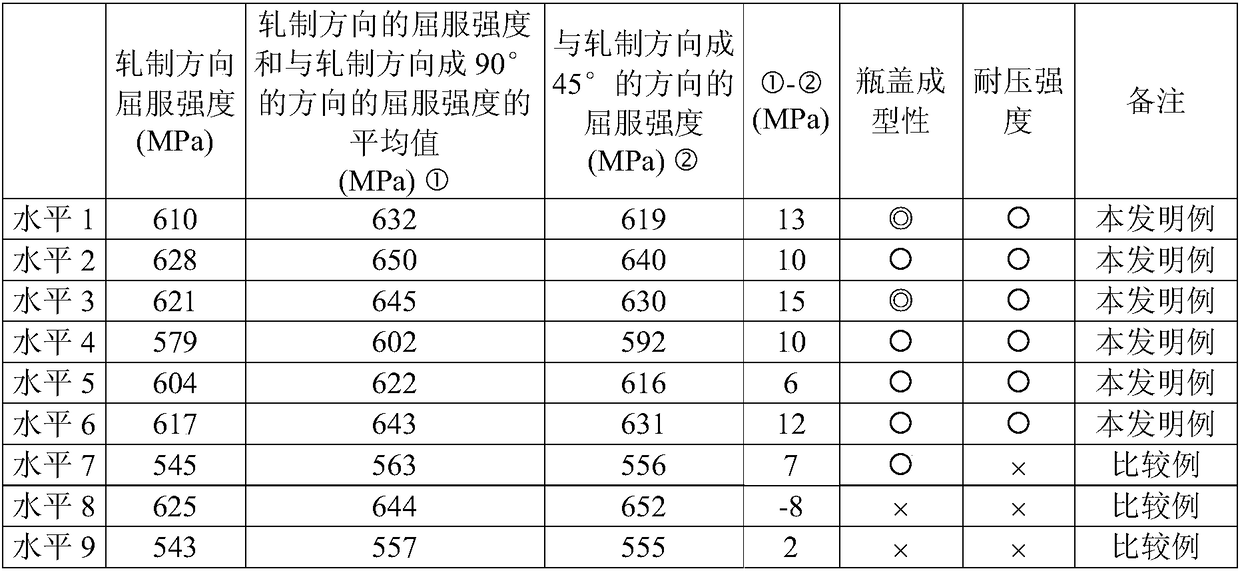

[0067] The steel was smelted in a converter and continuously cast to obtain a slab. The steel had the composition shown in Table 1, and the balance was composed of Fe and unavoidable impurities. After heating the obtained slab to 1250°C, hot rolling was performed at a rolling start temperature of 1150°C and a finish rolling temperature of 860°C, and coiling was performed at the coiling temperature shown in Table 2. Next, after removing the scale by pickling, the primary cold rolling rate shown in Table 2 was used for primary cold rolling, and the annealing temperature was carried out in a continuous annealing furnace at the annealing temperature shown in Table 2, and the secondary rolling rate shown in Table 2 was used. The cold rolling ratio performs secondary cold rolling (DR rolling) to obtain a steel plate with a plate thickness of 0.15 to 0.18 mm (levels 1 to 9). For both sides of the obtained steel plate, implement 100 mg / m on each side 2 Cr-plated to get tin-free steel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com