Self-propelled leaf vegetable harvester

A self-propelled, harvester technology, applied in the field of harvesters, can solve the problems of large machine body, poor cutting adaptability, uneven cutting, etc., and achieve the effect of ensuring harvest quality, avoiding cutting loss, and avoiding damage and damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

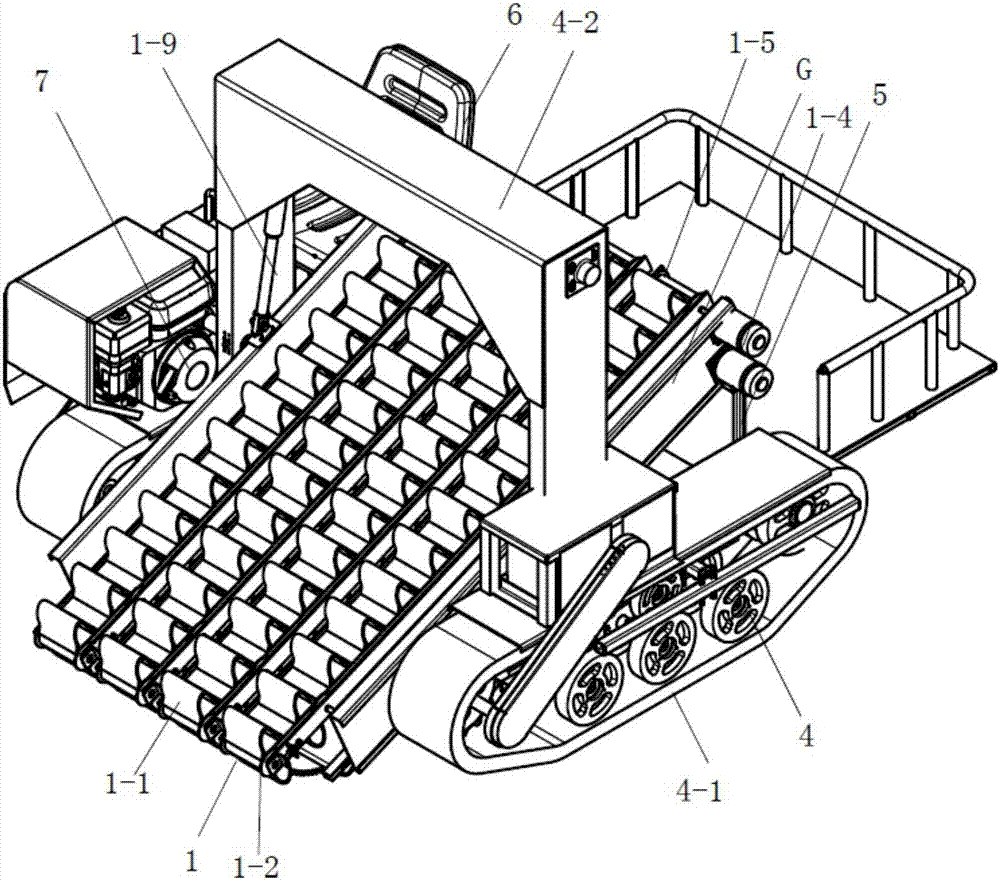

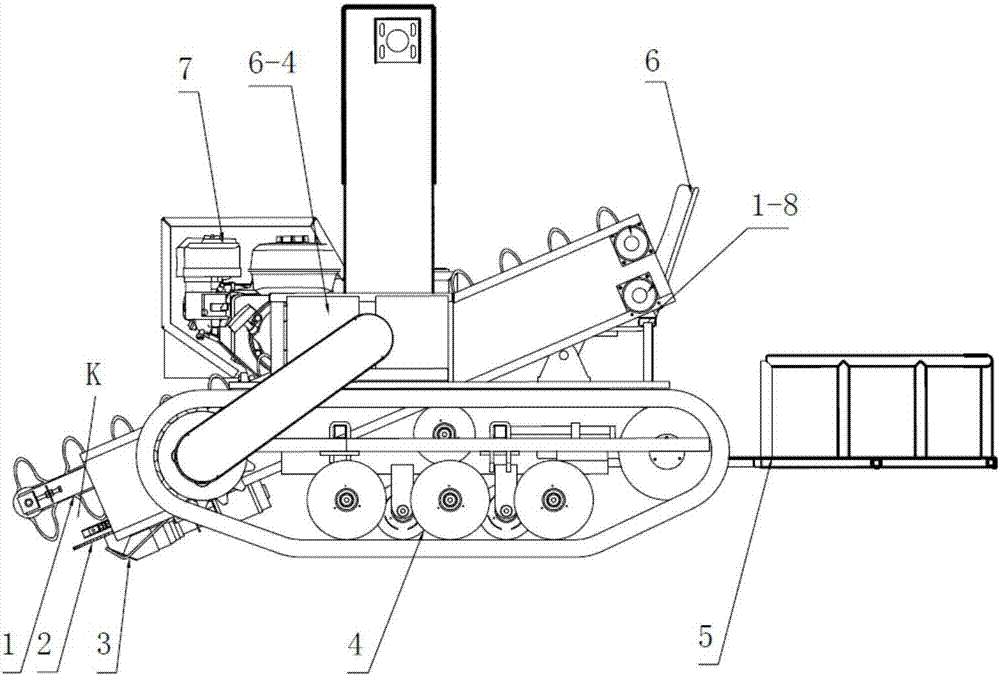

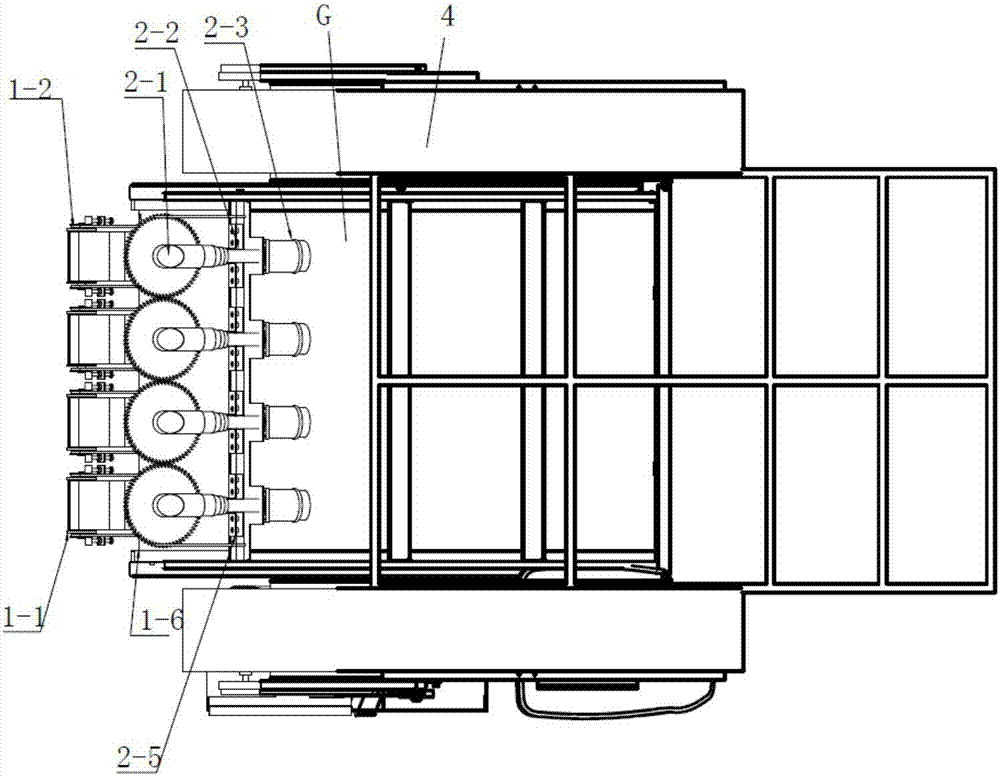

[0018] The basic structure of the self-propelled leaf vegetable harvester of the present embodiment is as follows: figure 1 and figure 2 As shown, it includes a gantry 4-2 straddling the crawler chassis 4 (for the specific structure of the gantry 4-2, please refer to the Chinese patent document with application number 200910026164.0) and a driving system 6 located on one side of the crawler chassis. The profiling conveying device 1 positioned on the header frame G is mounted on the crawler chassis 4 .

[0019] The front end of the profiling conveying device 1 is positioned at the front and bottom of the crawler chassis 4 , and the rear end extends through the gantry 4 - 2 and is positioned at the rear top of the crawler chassis 4 . The profiling conveying device 1 is made up of four pairs of vertically encircling lower lifting conveyer belts 1-6 and vertically encircling upper corrugated conveyer belts 1-1 which are paired to form a spaced profiling space K. The entry end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com