Integrated brush and integrated brush injection mold

An injection mold, integrated technology, applied in coating and other directions, can solve the problems of increasing material input cost, difficult to unify product specifications, loose and lint, etc., to reduce material cost investment, firm and reliable bonding, and avoid loosening and falling off. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

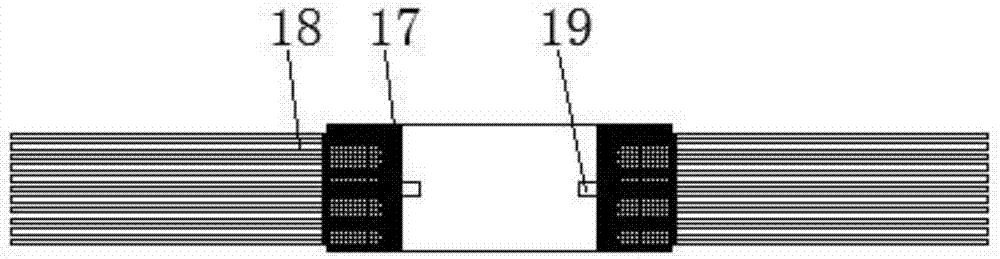

[0017] An integrated brush, including a brush handle 17 and a brush wire 18, the brush handle 17 and the brush wire 18 are made of composite plastic materials of PP, PVC, PBT, PET or any combination thereof, and the brush handle 17 is Straight column ring structure or wavy ring structure, the brush filaments 18 are evenly distributed along the circumference of the brush handle 17, the brush handle 17 is formed by injection molding, and is integrally formed with the brush filaments 18 by injection molding, and the inner wall of the brush handle 17 is provided with two There are three connecting columns 19, and two connecting columns 19 are symmetrically distributed.

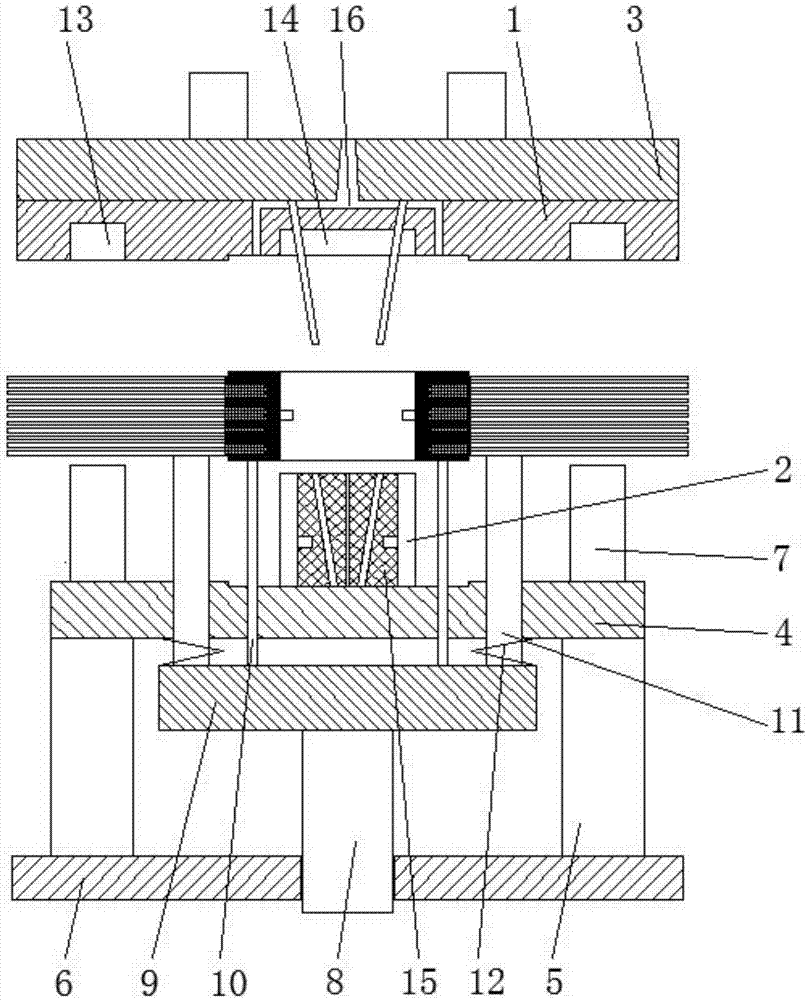

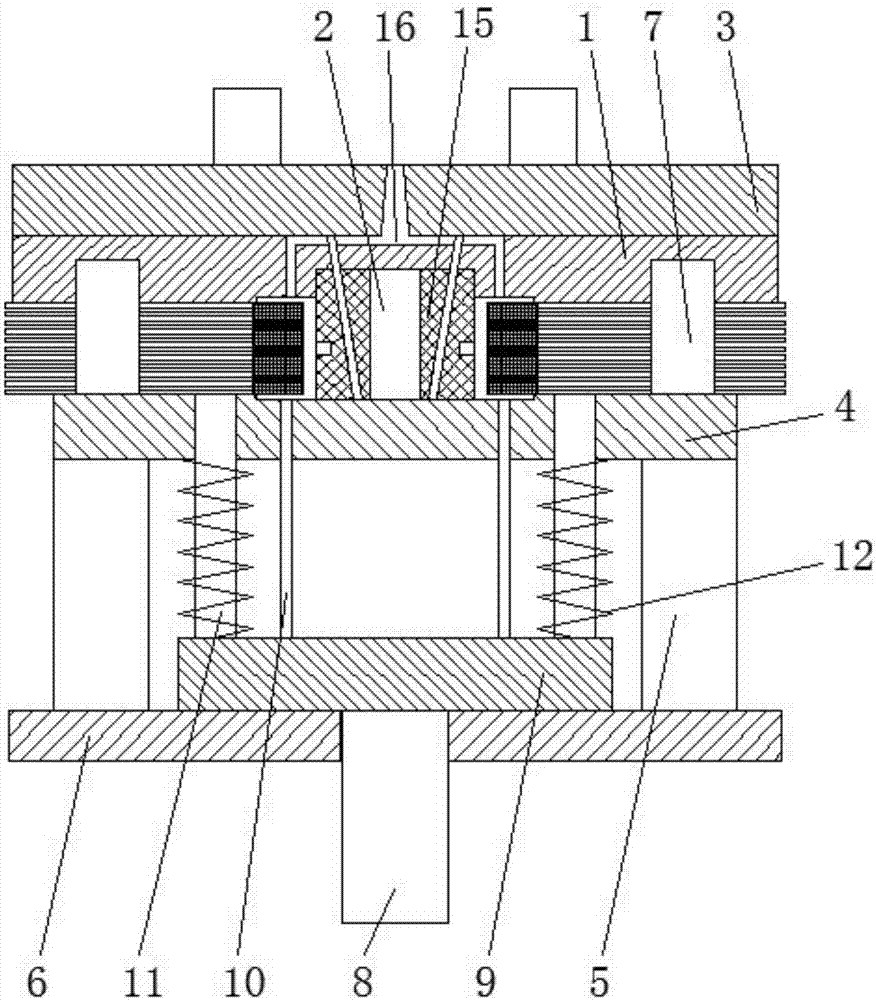

[0018] An injection mold for an integrated brush, including a fixed mold 1 and a movable mold 2, the movable mold 2 is located below the fixed mold 1, the fixed mold 1 is installed at the bottom of the fixed template 3 of the injection molding machine, and the movable mold 2 is installed on the injection molding ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com