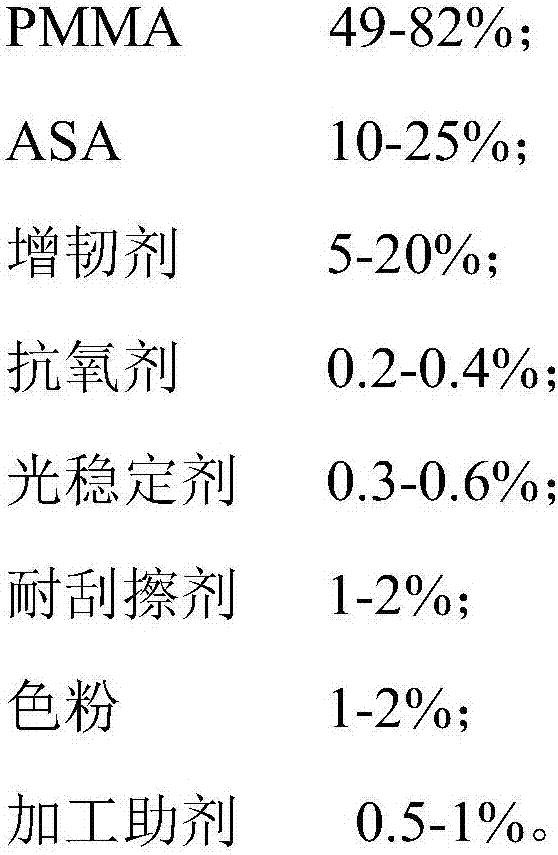

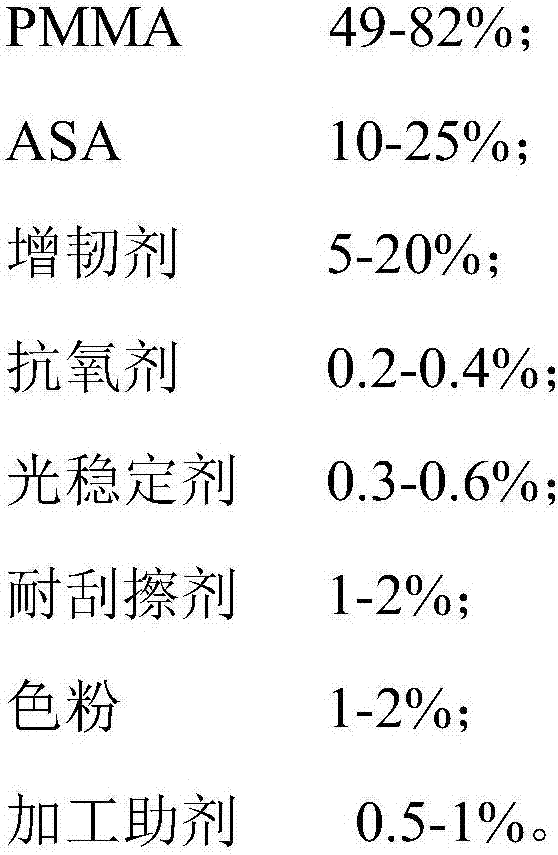

PMMA/ASA composite material and preparation method thereof

A composite material and content technology, applied in the field of PMMA/ASA composite material and its preparation, can solve the problems of poor strength, abrasion resistance and toughness, unbalanced overall performance, etc., and achieve low cost, overall rigidity and toughness balance, The effect of simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] On the other hand, an embodiment of the present invention provides a method for preparing a PMMA / ASA composite material. This preparation method comprises the steps:

[0027] S01: Weigh the raw materials of each component according to the ingredients and content contained in the above PMMA / ASA composite material, and mix them to obtain a mixed material;

[0028] S02: put the above mixed material into a twin-screw extruder, and granulate through melt extrusion.

[0029]The preparation method of the PMMA / ASA composite material has simple process and low cost, and the overall performance of the finally obtained PMMA / ASA composite material is rigid and tough, with high strength, scratch resistance, toughness, and beautiful appearance, which is very suitable for use In the automotive industry, electronic and electrical industries and other outdoor products and other fields.

[0030] Preferably, in the above step S02, the process parameters of the twin-screw extruder are: t...

Embodiment 1

[0033] A kind of PMMA / ASA composite material, its formula sees embodiment 1 in table 1. The preparation method of this PMMA / ASA composite material comprises the steps:

[0034] S11: According to the ingredients and contents contained in the PMMA / ASA composite material of Example 1 in Table 1, the raw materials of each ingredient were weighed and mixed to obtain a mixed material.

[0035] S12: put the above mixed material into a twin-screw extruder, melt and blend, extrude and granulate to form a composite material. The process parameters of the twin-screw extruder are: the temperature of the first zone is 160°C, the temperature of the second zone is 180°C, the temperature of the third zone is 180°C, the temperature of the fourth zone is 170°C, the temperature of the head is 190°C, and the residence time is 3min -4min, the pressure is 15MPa.

Embodiment 2

[0037] A kind of PMMA / ASA composite material, its formula sees embodiment 2 in table 1. The preparation method of this PMMA / ASA composite material comprises the steps:

[0038] S21: According to the ingredients and contents contained in the PMMA / ASA composite material of Example 2 in Table 1, the raw materials of each ingredient were weighed and mixed to obtain a mixed material.

[0039] S22: put the above mixed material into a twin-screw extruder, melt and blend, extrude and granulate to form a composite material. The process parameters of the twin-screw extruder are: the temperature of the first zone is 170°C, the temperature of the second zone is 190°C, the temperature of the third zone is 190°C, the temperature of the fourth zone is 180°C, the temperature of the head is 200°C, and the residence time is 3min -4min, the pressure is 15MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com