A kind of pet/pbe composite material and preparation method thereof

A composite material and polymer material technology, applied in the field of polymer material preparation, can solve the problem of unfavorable mutual diffusion and penetration of polymer molecules, reduce the fragmentation and dispersion effect of dispersed phase particles, and poor plasticizing and mixing effects of blends, etc. The problem is to achieve the effect of simple preparation method, small particle size and improved material toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This example provides 12 kinds of PET / PBE composite materials and their preparation methods, and provides 8 groups of corresponding comparison examples.

[0034] According to the formulas of Comparative Examples 1-8 and Examples 1-12 shown in Table 1, the ingredients were mixed, mixed in a high-speed mixer for 10 minutes, and then melted and blended using polymer material plasticizing and transporting equipment based on extensional rheology , the temperature of each section is 230-250-260-265-265 ℃, the rotor speed is 30 rpm, extruded, cooled, air-dried, pelletized, and dried to obtain 4 kinds of PET / PBE without compatibilizer Composite materials, 4 kinds of PET materials without PBE and 12 kinds of PET / PBE composite materials with compatibilizer added.

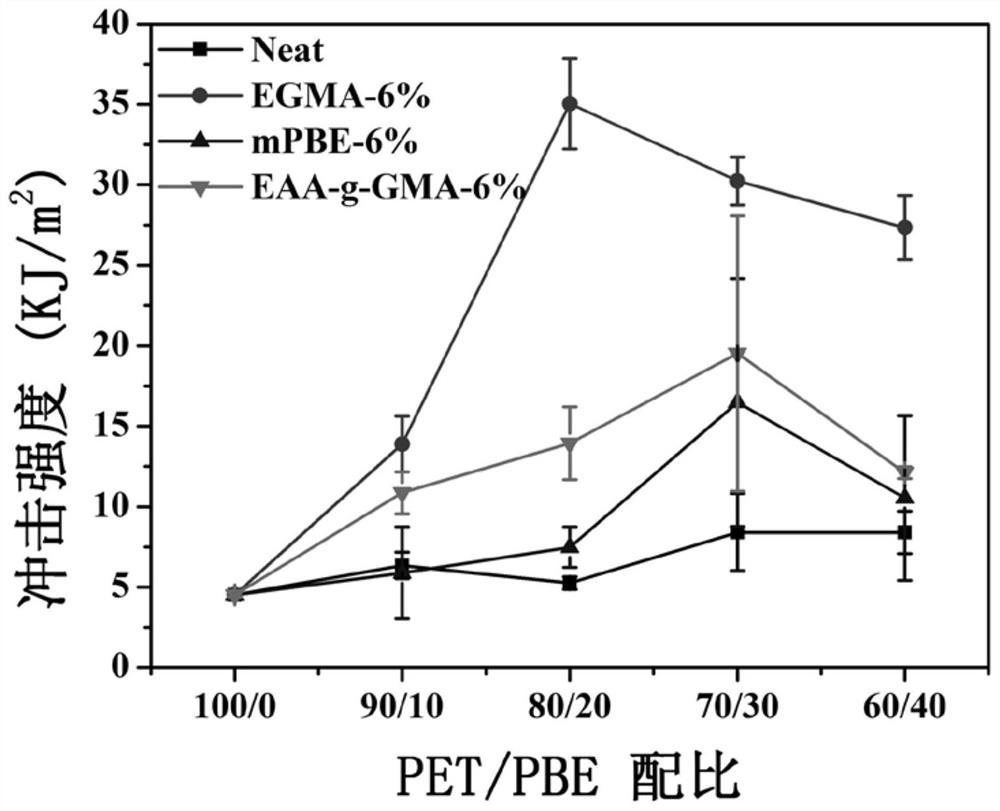

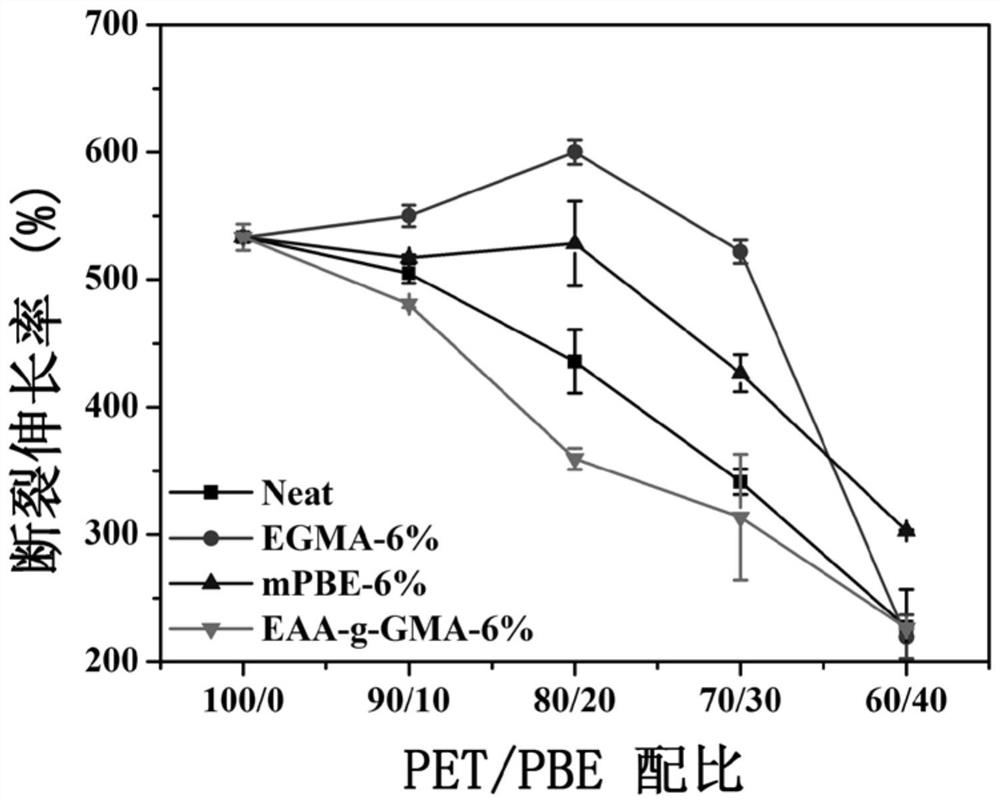

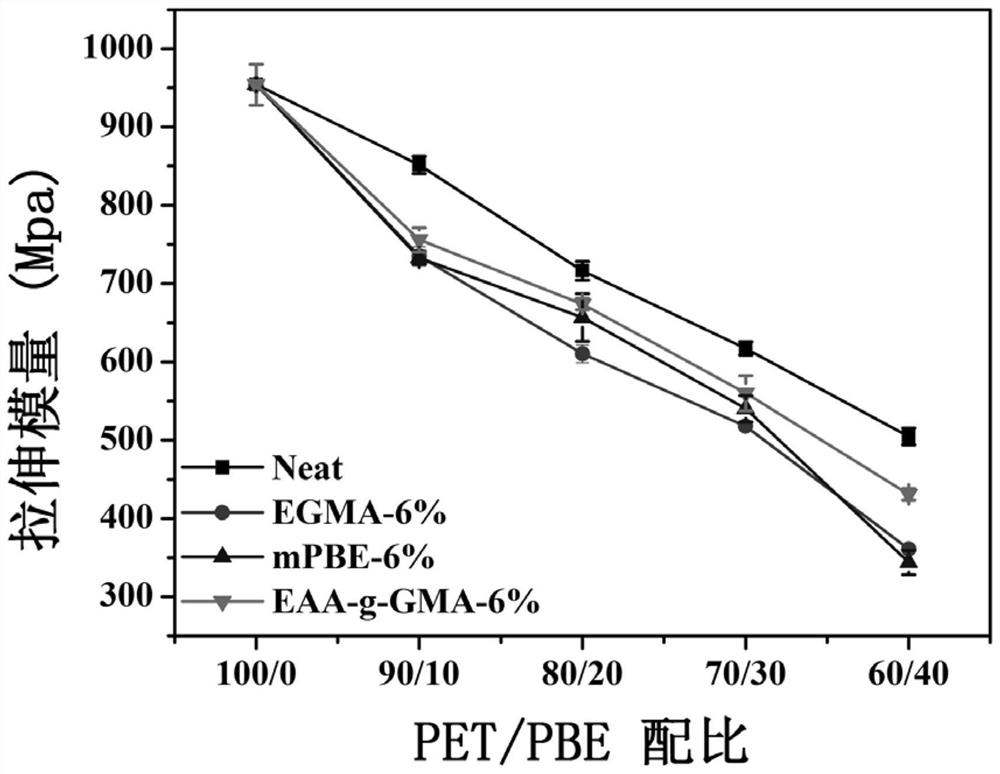

[0035] Dry the above materials in a vacuum drying oven at 105°C for 12 hours, then inject a standard sample on the injection molding machine, and perform tensile and impact performance tests according to GB / T 1040-2006...

Embodiment 2

[0040] This example provides 5 kinds of PET / PBE composite materials and their preparation methods, and provides a corresponding set of control examples.

[0041] According to Comparative Example 9 shown in Table 2, the formulas of Examples 13 to 17 were mixed and batched, mixed in a high-speed mixer for 30 minutes, and then melted and blended using polymer material plasticizing and transporting equipment based on extensional rheology. The section temperature is 230-250-260-265-265°C, the rotor speed is 30 rpm, extruded, cooled, air-dried, pelletized, and dried to obtain a PET / PBE composite material without compatibilizer , 5 PET / PBE composites with different compatibilizer content.

[0042] Dry the above materials in a vacuum drying oven at 105°C for 12 hours, then inject a standard sample on the injection molding machine, and perform tensile and impact performance tests according to GB / T 1040-2006 and GB / T 1043-2000. The results are as follows Figure 4~6 shown. Among them,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com