Preparation method of phosphatized sol flame retardant polyurethane powder coating

A polyurethane powder and sol technology, which is applied in powder coatings, fireproof coatings, coatings, etc., can solve the problems of poor surface stability, poor compatibility, and poor flame retardancy of coating films, and achieve good safety and environmental protection. Capacitance, the effect of improving stability and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

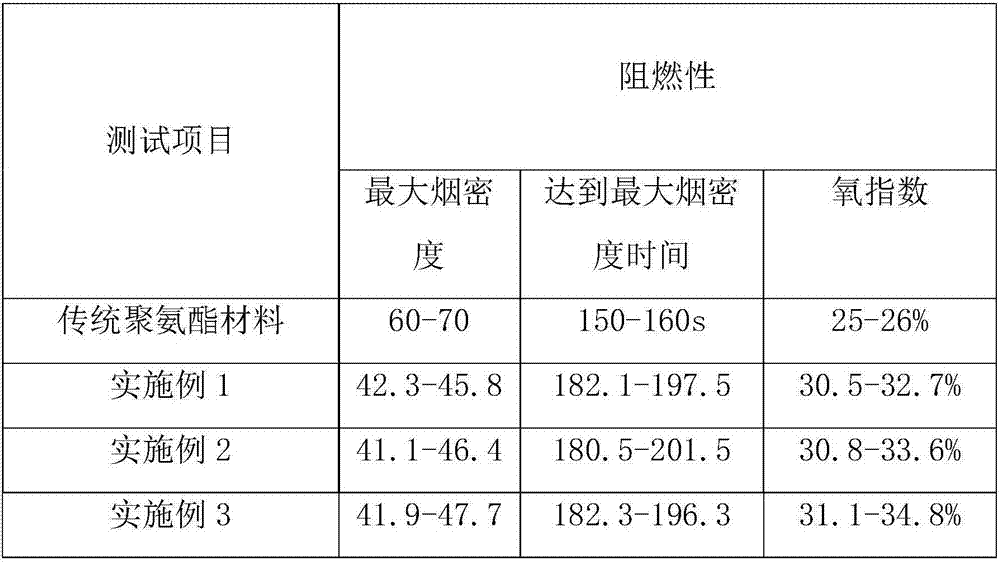

Examples

Embodiment 1

[0022] A preparation method of phosphating sol flame-retardant polyurethane powder coating, comprising the following steps:

[0023] (1) Mix 0.3 parts by weight of urotropine and 16 parts by weight of zirconium oxychloride, add to deionized water 80 times the weight of the mixture, raise the temperature to 50°C, heat and stir for 20 minutes to obtain water dispersion liquid;

[0024] (2) Take 5 parts by weight of zinc acetate and 6 parts by weight of stannous chloride and mix them, add them to deionized water 200 times the weight of the mixture, stir evenly, send them into a constant temperature water bath at 85°C, add the above water to disperse solution, keep stirring for 100 minutes, add 1 mol / l ammonia water dropwise, adjust the pH to 12, keep stirring for 6 hours, discharge, centrifuge, wash the precipitate with water, and dry at 50°C for 1 hour in vacuum to obtain a hydroxyl filler;

[0025] (3) get the calcium ricinoleate of 0.7 weight part, join in the ethanol solutio...

Embodiment 2

[0034] A preparation method of phosphating sol flame-retardant polyurethane powder coating, comprising the following steps:

[0035] (1) Mix 0.5 parts by weight of urotropine and 20 parts by weight of zirconium oxychloride, add to deionized water 100 times the weight of the mixture, raise the temperature to 68 ° C, keep stirring for 20 minutes, and obtain water dispersion liquid;

[0036] (2) Take 7 parts by weight of zinc acetate and 8 parts by weight of stannous chloride and mix them, add them to deionized water 200 times the weight of the mixture, stir evenly, send them into a constant temperature water bath at 85°C, add the above water to disperse solution, keep stirring for 100 minutes, add 2 mol / l ammonia water dropwise, adjust the pH to 12, keep stirring for 6 hours, discharge, centrifuge, wash the precipitate with water, and dry at 50°C for 2 hours in a vacuum to obtain a hydroxyl filler;

[0037] (3) get the calcium ricinoleate of 2 weight parts, join in the ethanol ...

Embodiment 3

[0046] A preparation method of phosphating sol flame-retardant polyurethane powder coating, comprising the following steps:

[0047] (1) Mix 0.3 parts by weight of urotropine and 16 parts by weight of zirconium oxychloride, add to deionized water 80 times the weight of the mixture, raise the temperature to 50°C, keep stirring for 10 minutes, and obtain water dispersion liquid;

[0048] (2) Take 5 parts by weight of zinc acetate and 6 parts by weight of stannous chloride and mix them, add them to deionized water 170 times the weight of the mixture, stir evenly, send them into a constant temperature water bath at 80°C, add the above water to disperse solution, kept stirring for 70 minutes, added dropwise 1mol / l ammonia water, adjusted the pH to 11, kept stirring for 5 hours, discharged, centrifuged, washed the precipitate with water, and dried at 40°C for 1 hour in vacuum to obtain a hydroxyl filler;

[0049] (3) get the calcium ricinoleate of 0.7 weight part, join in its weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com