A high-speed percussion drilling tool

A drilling tool and high-speed impact technology, which is applied to drilling equipment, driving devices for drilling in boreholes, earthwork drilling and production, etc., can solve the problems of low efficiency in hard formations and increased drilling costs, and achieve favorable crushing, reliable performance, and high speed high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

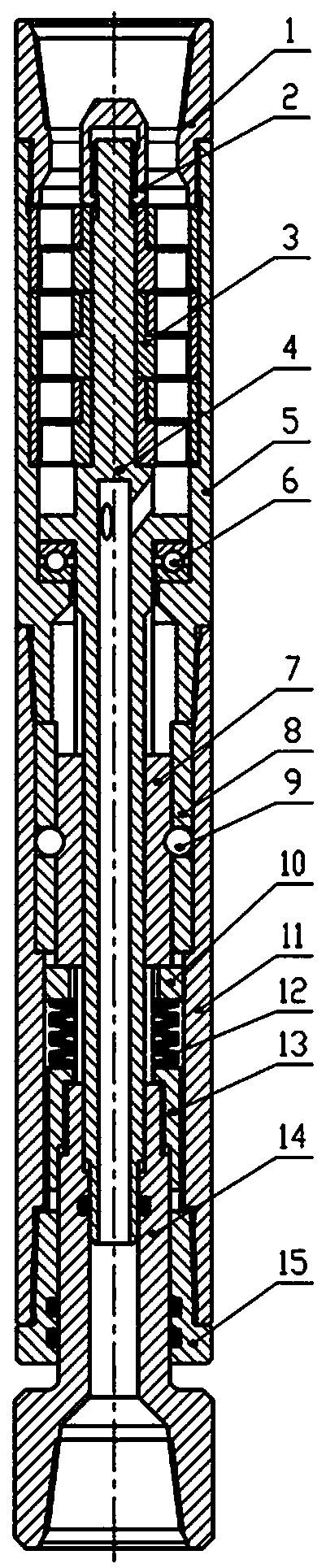

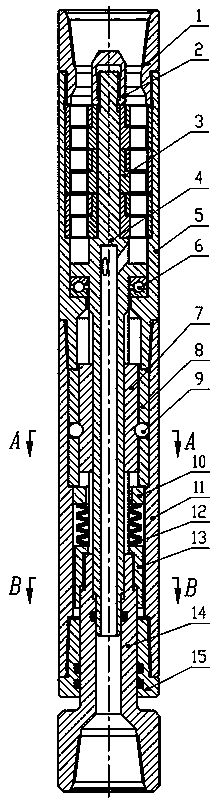

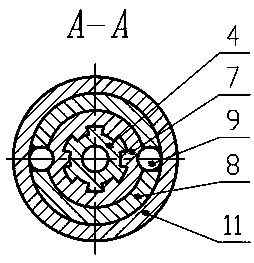

[0014] Such as figure 1 and figure 2 As shown, a high-speed impact drilling tool is composed of an upper joint 1, a locking cap 2, a turbine assembly 3, a rotating shaft 4, a power housing 5, a thrust bearing 6, a hammer body 7, a sleeve 8, a steel ball 9, Hammer and anvil cylinder 10, outer cylinder 11, disc spring 12, disc spring seat 13, drive shaft 14 and anti-drop cap 15 constitute; Drill bit screw connection; a stepped surface is set in the middle of the inner cavity of the power housing 5, and a circle of raised steps is set at the lower part of the inner cavity of the power housing 5; the turbine assembly 3 is assembled from turbine stator blades and turbine rotor blades, and the turbine assembly 3 Put it into the inner cavity of the power housing 5; the lower end of the upper joint 1 is connected with the upper end of the power housing 5 with screws, and the lower end surface of the upper joint 1 and the step surface in the middle of the inner cavity of the power ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com