A high temperature abrasive jet drilling system and drilling method

A kind of abrasive jet, high temperature technology, applied in abrasives, application of thermal energy drilling, sputtering coating and other directions, to achieve the effect of intensifying thermal cracking, increasing ROP, and improving oil and gas recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

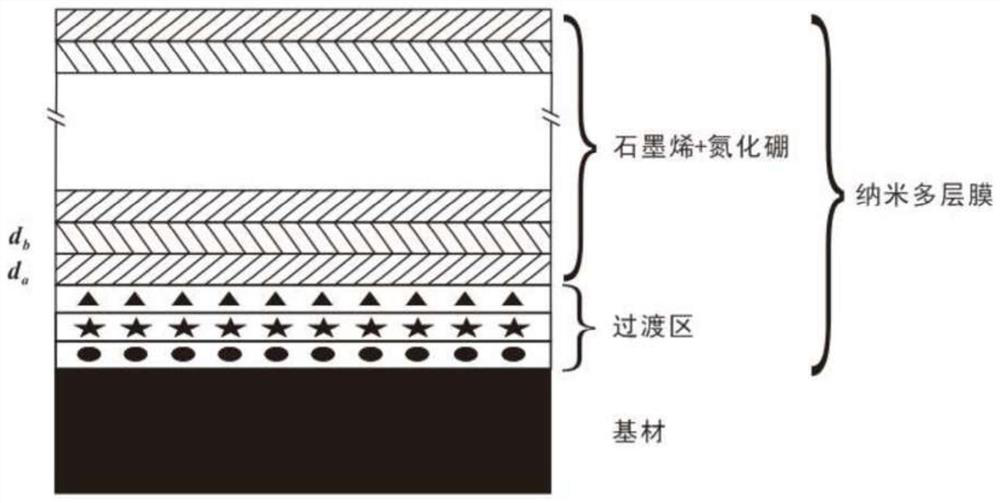

[0103] 1. Preparation of transition layer

[0104] (1) Nozzle base material cleaning: Use ion beam to bombard the nozzle (the material is hard alloy). The furnace pressure is 0.1Pa, the Ar gas flow rate is 100sccm, the ion source is 0.5Kw, the magnetron frequency is 1Kw, and the negative bias voltage is 35V for 40min.

[0105] (2) Preparation of Ti metal transition layer: double Ti targets are used. The pressure in the furnace is 0.1Pa, the Ar gas flow rate is 100sccm, the ion source is 0.5Kw, the magnetron frequency is 1Kw, the target power is 1Kw, the negative bias voltage is 35V, and the time is 5min.

[0106] (3) Preparation of TiC transition layer: double Ti targets are used. The pressure in the furnace is 0.1Pa, the flow rate of Ar gas is 100sccm, CH 4 The gas flow is 10sccm, the ion source is 0.5Kw, the magnetron frequency is 1Kw, the target power is 1Kw, the negative bias voltage is 35V, and the time is 5min.

[0107] (4) Preparation of TiCN transition layer: doubl...

Embodiment 1

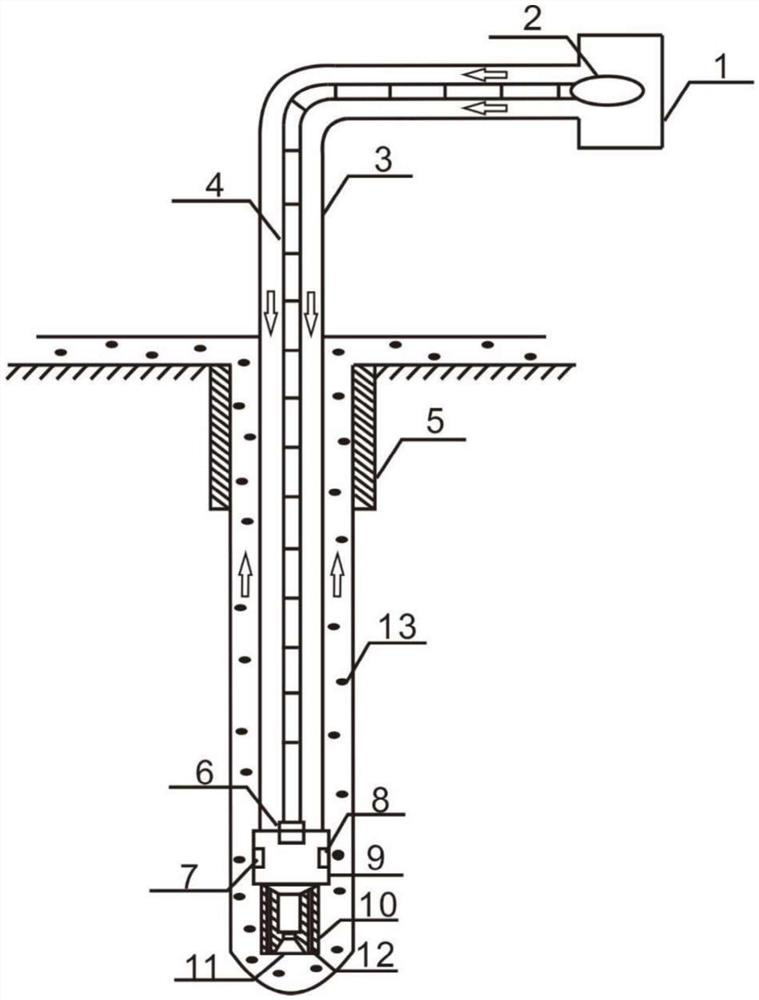

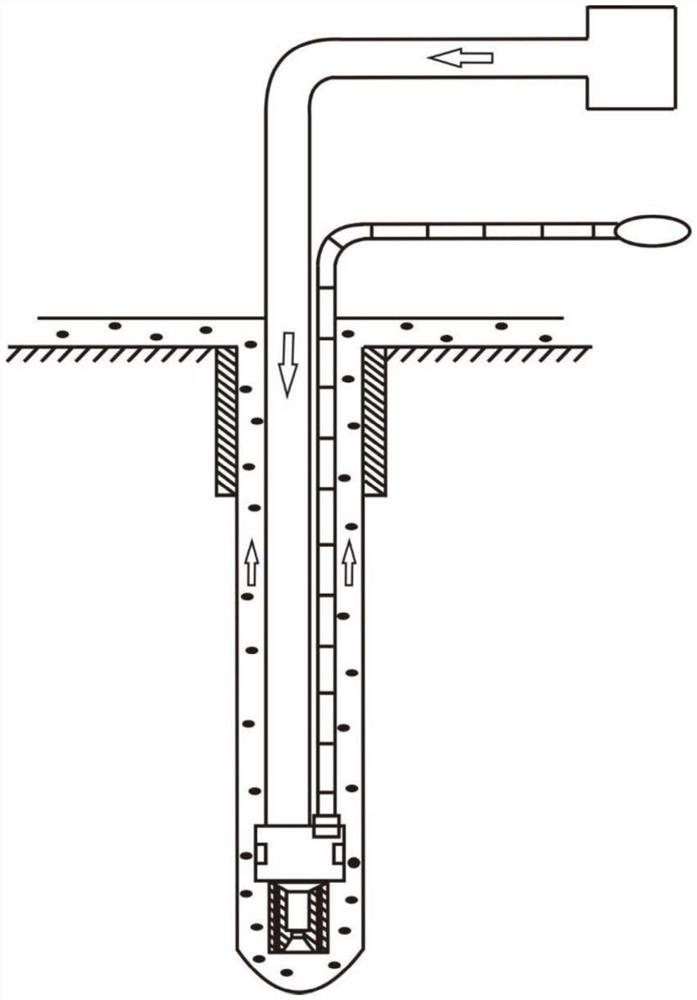

[0115] The high-temperature abrasive jet drilling system includes a surface pump unit 1, a microwave generator 2, a coiled tubing 3, a waveguide 4, a microwave antenna 6, a heating chamber 9, a temperature sensor 7, a pressure sensor 8, a high-temperature abrasive jet device 10, etc., combined with Accompanying drawing 2 further introduces the flow process of technology:

[0116] 1. Drain the well, wash the well, and prepare for the operation;

[0117] 2. Utilize the waveguide 4 to connect the microwave antenna 6 to the heating cavity 9 at the end of the coiled tubing 3;

[0118] 3. Turn on the surface pump unit 1, and use the coiled tubing 3 to pump water, microwave strong absorbent and abrasive particles into the heating chamber 9;

[0119] 4. Turn on the microwave generating device 2, and the microwave antenna 6 starts to radiate the water and microwave strong absorbent in the heating chamber 9. The internal temperature and pressure are monitored by the temperature sensor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com