Staged hard rock breaking hob drill bit

A graded, drill bit technology, applied in drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems of low drilling efficiency and long construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

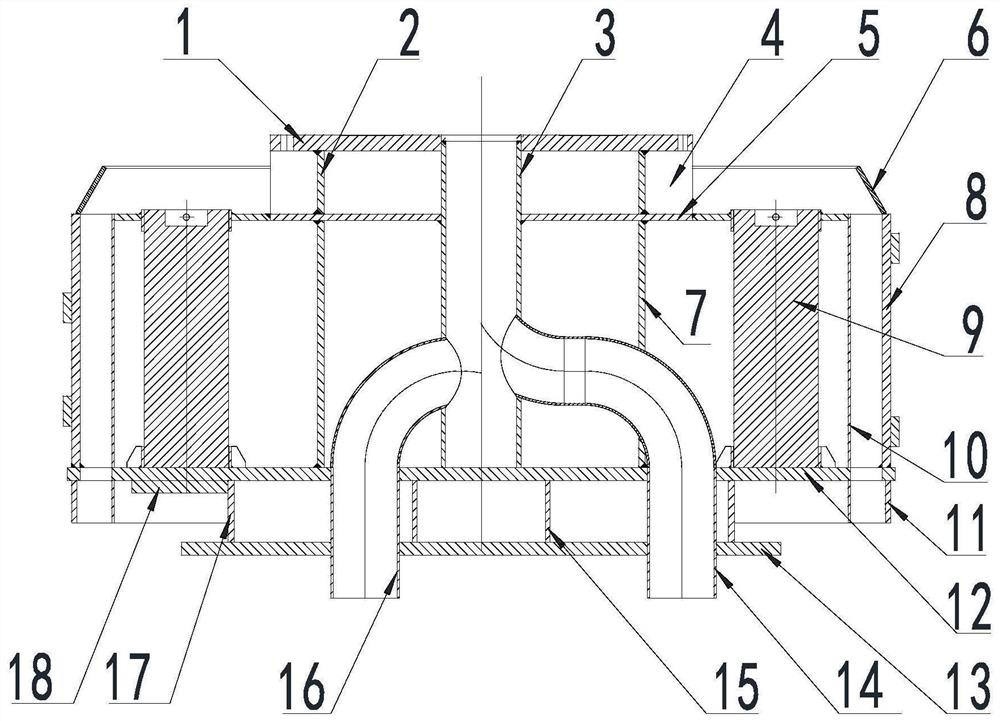

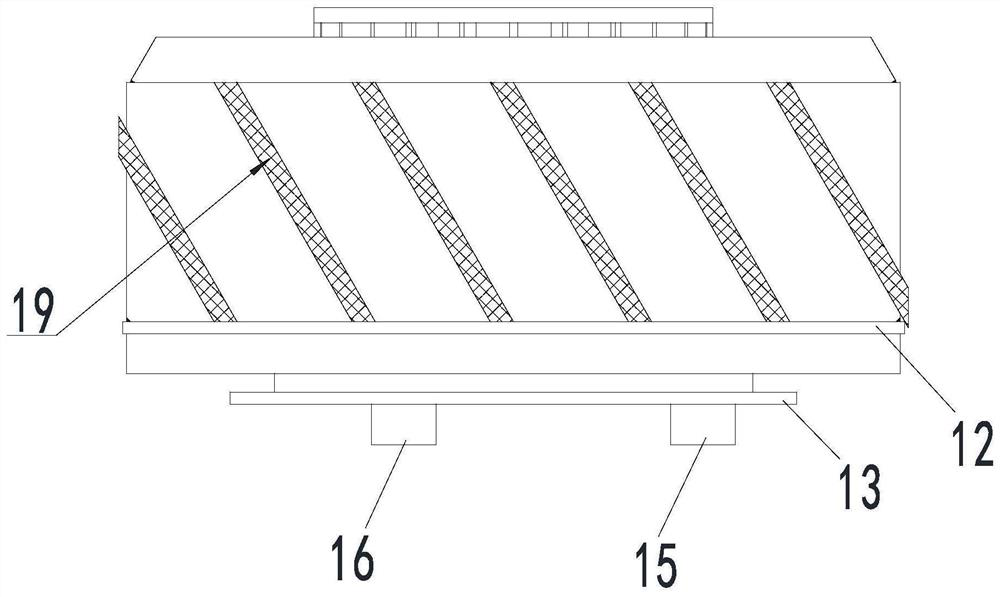

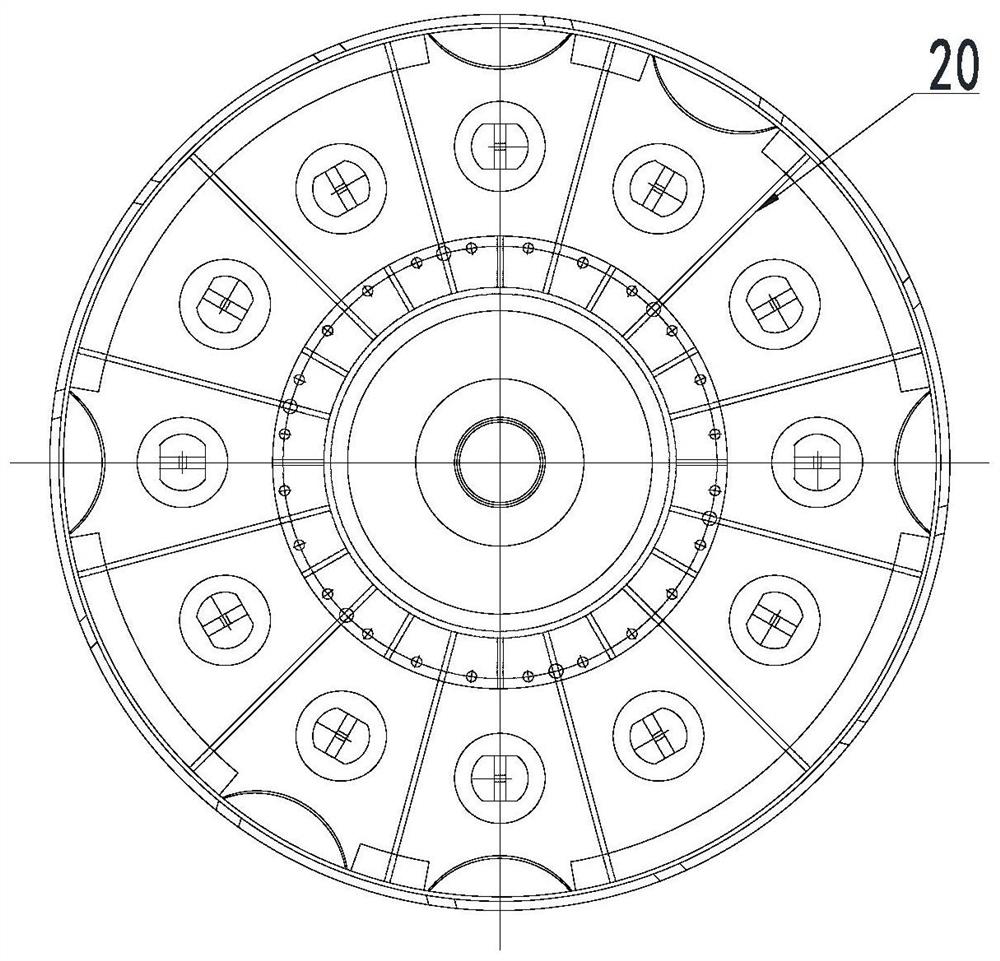

[0030] see Figure 1-7 : a graded rock-breaking hard rock hob drill bit, comprising a drill body, the working end of the drill body is provided with a secondary cutterhead 12 and a primary cutterhead 13 with a height difference from the inside to the outside, the primary cutterhead 13 The rear ends of the cutterhead 13 and the secondary cutterhead 12 are respectively connected to drilling tool systems of different frequencies to realize frequency division drilling, and the front ends of the first-stage cutterhead 13 and the second-stage cutterhead 12 are respectively used to connect the cutter holder and the hob 26. A slurry replenishing device is provided on the outer periphery of the working end of the drill body, and a slurry suction device is provided on the primary cutter head 13 .

[0031] The primary cutterhead of this embodiment is ahead of the secondary cutterhead, so that during the drilling process, large and small holes with a height difference of 115mm will be for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com