An exhaust muffler for a screw unit

An exhaust muffler, screw-type technology, applied in the components of pumping devices for elastic fluids, machines/engines, rotary piston/oscillating piston pump components, etc., can solve the pressure loss, affect the size of the unit, The muffler has problems such as narrow muffling bandwidth, and achieves the effect of reducing local pressure loss, reducing pressure loss along the way, and small pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

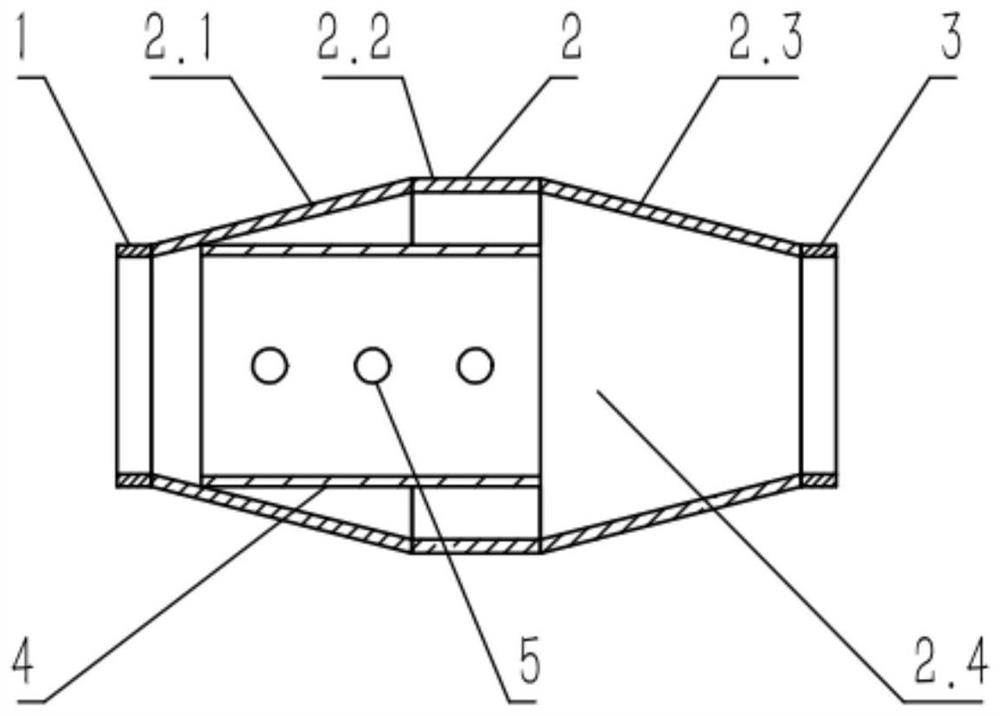

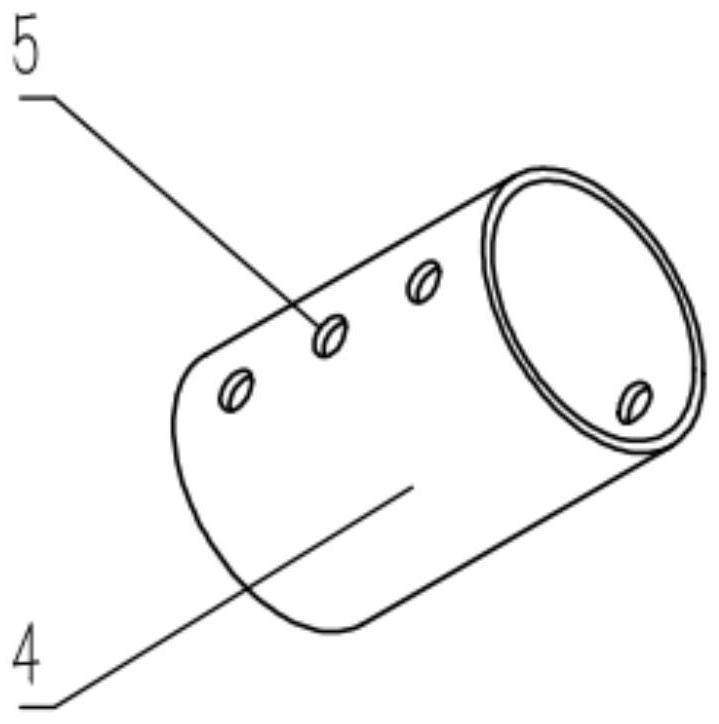

[0036] like Figure 1-3The exhaust muffler shown for the screw type unit is composed of an air intake pipe 1, a muffler shell 2, an air outlet pipe 3, an air intake inner tube 4, and an air intake inner tube air hole 5. The air inlet pipe 1 and the air outlet pipe 3 are opposite to each other from both ends and communicate with the two ends of the muffler housing 2 respectively. and the outlet pipe 3 are fixedly connected to the muffler housing 2 respectively, and the connection is sealed. The muffler shell 2 is composed of an expander tube 2.1, a straight tube 2.2, and a reducer tube 2.3 according to the flow direction of the refrigerant; the muffler shell 2 is arranged with an air inlet insert pipe 4, and the air inlet insert pipe 4 is fixed on the gradually On the expander 2.1, the intake inner insert 4 is inserted into the muffler cavity 2.4 from the junction with the gradual expander 2.1; the intake insert 4 is provided with an air intake inner insert pore 5 .

[0037] ...

Embodiment 2

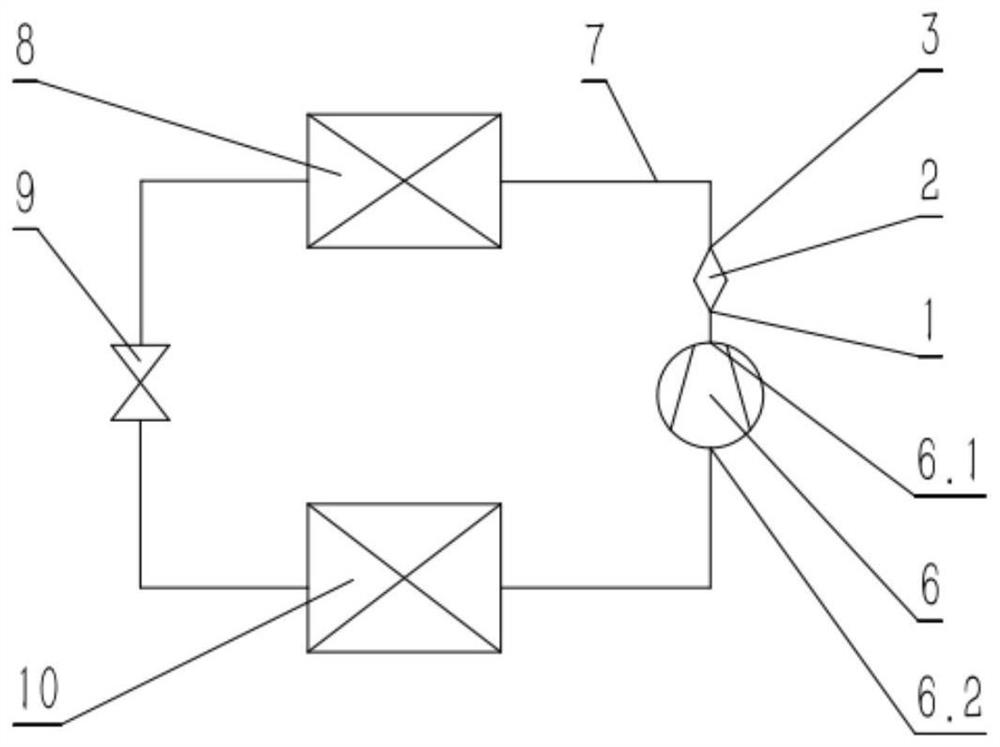

[0050] like Figure 2-4 The exhaust muffler shown for the screw unit has the same structure as that of Embodiment 1, the difference is that an inner insert is set in the reducer 2.3 at the air outlet. After adopting the structure of this embodiment, only the Helmholtz resonant cavity structure is retained, and various partition structures are omitted to obtain the same noise reduction effect as that of Patent No. 201520276726.8. The pressure loss trend of this example is also consistent with Figure 8 And Table 1, the content corresponding to the pressure loss in the chart is: the inner diameter of the inner intubation tube is the same as the inner diameter of the outlet pipe or larger than the inner diameter of the outlet pipe.

Embodiment 3

[0052] like figure 2 , 3 The exhaust muffler used for the screw type unit shown in .5, on the basis of embodiment 1, an air outlet inner tube 14 is added, and a hole is correspondingly added between the air inlet inner tube 4 and the air outlet inner tube 14 Plate 11. All the other are the same with embodiment 1.

[0053] In detail, such as figure 2 , 3 , 5. The exhaust muffler for the screw unit is composed of an air inlet pipe 1, a muffler shell 2, an air outlet pipe 3, an air inlet inner pipe 4, an orifice plate 11, and an air outlet inner pipe 14. The air inlet pipe 1 and the air outlet pipe 3 are opposite to each other from both ends and communicate with the two ends of the muffler housing 2 respectively. and the outlet pipe 3 are fixedly connected to the muffler housing 2 respectively, and the connection is sealed. The muffler shell 2 is composed of an expander tube 2.1, a straight tube 2.2, and a reducer tube 2.3 according to the flow direction of the refrigeran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com