Real-time controllable microdrop arraying device and method based on lithium niobate sandwich structure chip

A sandwich structure and micro-droplet technology, applied in the field of real-time controllable micro-droplet array devices, can solve the problems of high device cost, inability to combine micro-droplets, complex chip structure, etc., and achieve low cost and real-time controllable process , The effect of simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

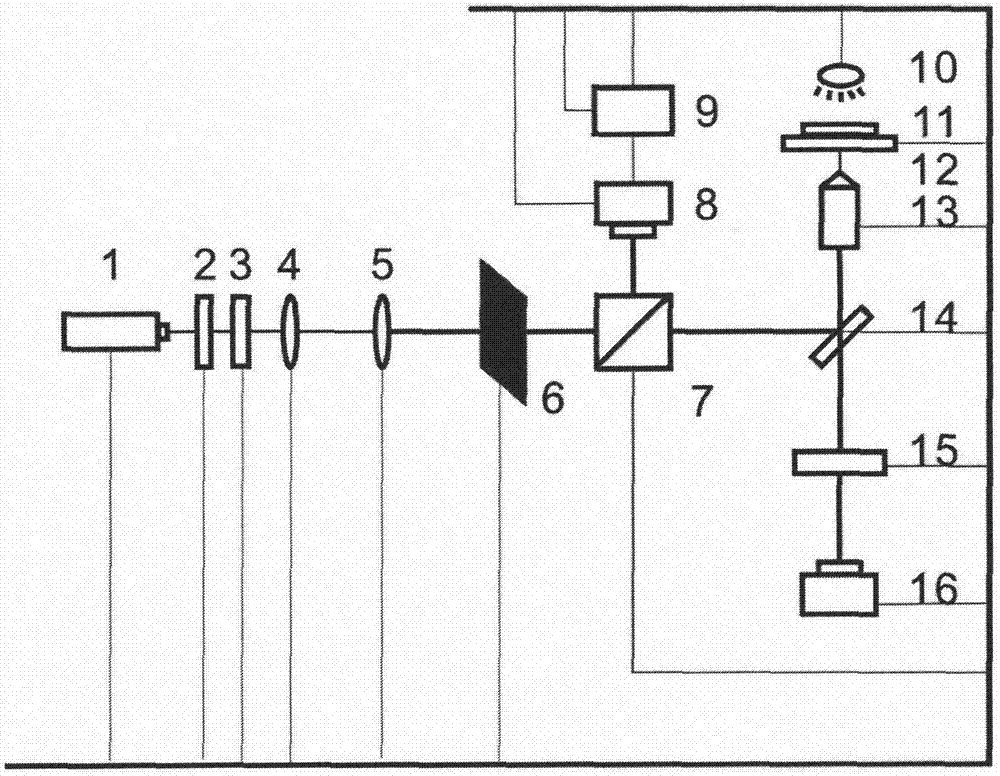

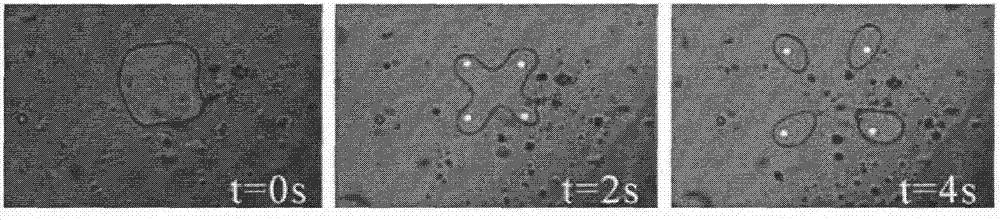

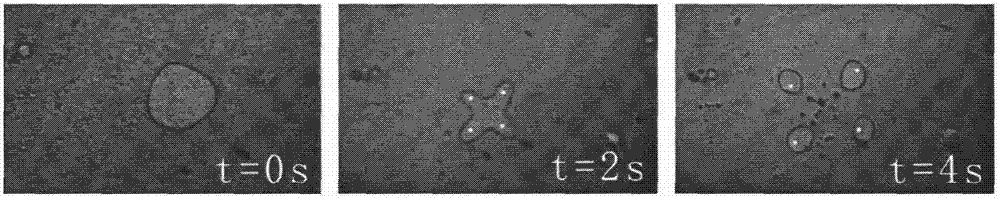

[0027] Using a 532nm laser, the laser power is 7.9mW, the focal length of the lens (1) is 15mm, and the focal length of the lens (2) is 250mm, the lithium niobate sandwich structure chip is selected from the lithium niobate wafer + C face -C face, and the focusing objective lens is enlarged The multiplier is 10 times. The micro-droplets with a volume of 0.407nL to be arrayed are introduced into the lithium niobate sandwich structure chip. The expanded laser beam passes through the mask with four centrally symmetrical holes. The transparent micro-movement chip translation stage moves the interlayer droplet so that the droplet is located in the center of the square formed by the four focused laser spots, and the volume of the small droplet obtained after arraying is 101.75pL.

Embodiment 2

[0029] Use a 405nm laser, the laser power is 8.1mW, the focal length of the lens (1) is 15mm, and the focal length of the lens (2) is 250mm. The lithium niobate sandwich structure chip is made of a lithium niobate chip + a piece of quartz on the C surface, and the focusing objective lens is enlarged The multiple is 10 times, and the micro-droplets with a volume of 0.308nL to be arrayed are introduced into the lithium niobate sandwich structure chip, and the expanded laser beam passes through the mask with four centrally symmetrical holes, forming a four-dimensional A spot array composed of four laser spots, through the comprehensive adjustment of the transparent micro-movement chip translation stage to move the interlayer droplets, makes the droplets located in the center of the square formed by the four focused laser spots, and the volume of the small droplets obtained after arraying is 77pL.

Embodiment 3

[0031] Using a 532nm laser, the laser power is 4.5mW, the focal length of the lens (1) is 15mm, and the focal length of the lens (2) is 250mm, the lithium niobate sandwich structure chip is selected from the lithium niobate wafer + C face -C face, and the focusing objective lens is enlarged The multiple is 10 times, and the micro-droplets with a volume of 0.348nL to be arrayed are introduced into the lithium niobate sandwich structure chip, and the expanded laser beam passes through the mask with four centrally symmetrical holes, forming a four-dimensional A spot array composed of four laser spots, through the comprehensive adjustment of the transparent micro-movement chip translation platform to move the interlayer droplets, makes the droplets located in the center of the square formed by the four focused laser spots, and the volume of the small droplets obtained after arraying is 87pL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com