Marker positioning method and system of calibration plate image

A positioning method and positioning system technology, applied in the field of marker positioning, can solve the problems of weak robustness, low algorithm efficiency, long running time, etc., and achieve the effect of improving positioning efficiency, reducing debugging difficulty, and ensuring positioning accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0049] Definitions of terms used in the present invention:

[0050] An image pyramid is a structure for explaining images at multiple resolutions. An image pyramid is a collection of progressively lower resolution images arranged in a pyramid shape. The bottom image of the pyramid is a high-resolution representation, while the top is a low-resolution representation.

[0051] Region of interest (ROI, region of interest), in machine vision, image processing, outlines the area that needs processing from the processed image with the mode such as box, circle, ellipse, irregular polygon, adopts rectangular square in the present embodiment frame.

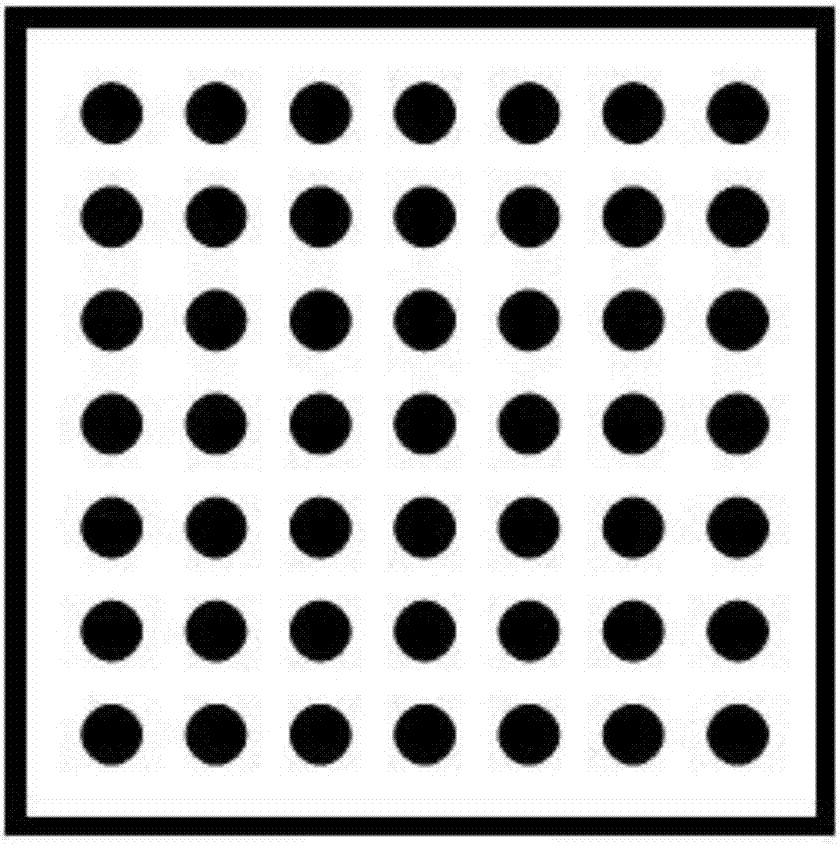

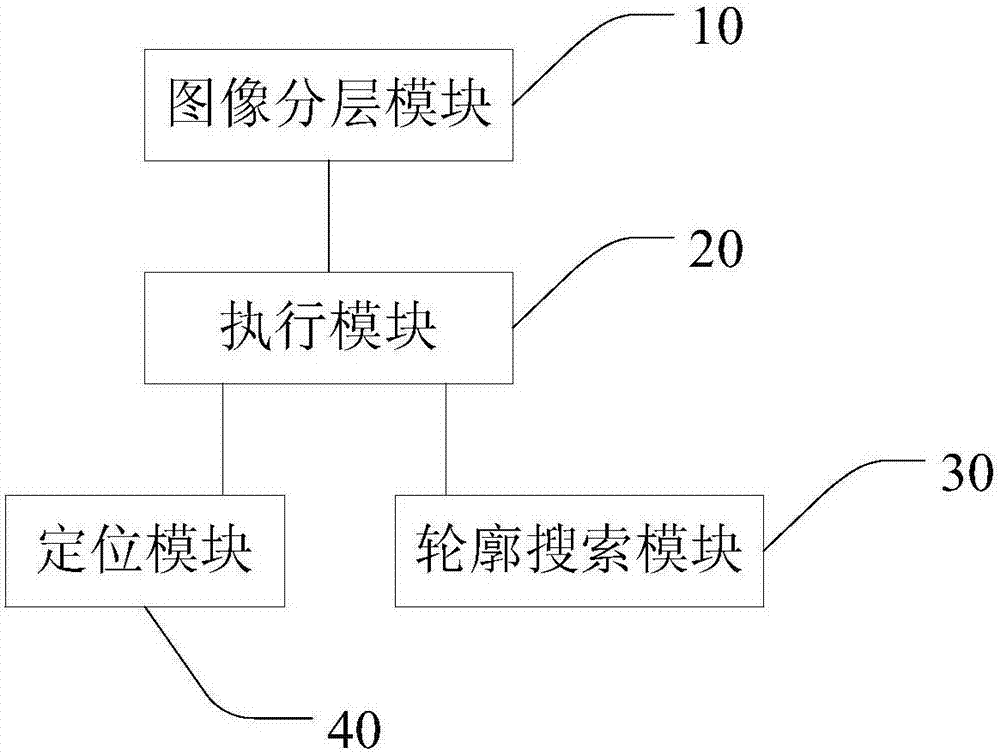

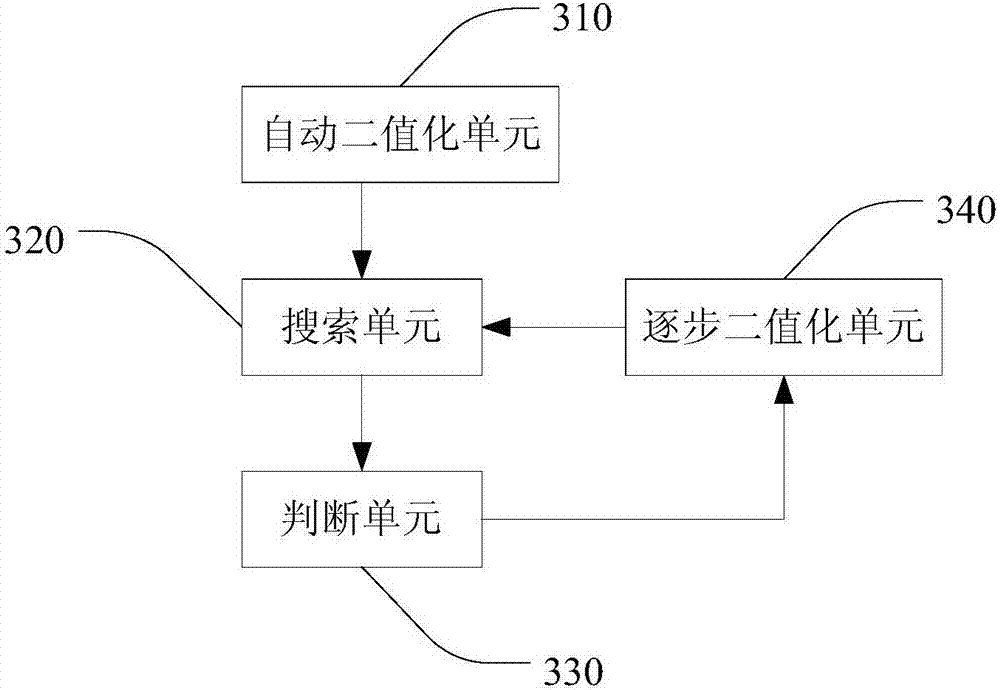

[0052] The present invention calculates the resolution size of the calibration board image (target image) to determine the required number of image pyramid layers; performs down-sampling of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com