Vertical photoelectric detector based on independent tin disulfide nanosheets and manufacturing method

A technology of photodetectors and tin disulfide, applied in the field of photodetectors, can solve the problems of serious reflection of incident light, complex electrical contact problems, limited light absorption capacity, etc., to achieve increased light absorption, good electrical contact, and good repeatability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

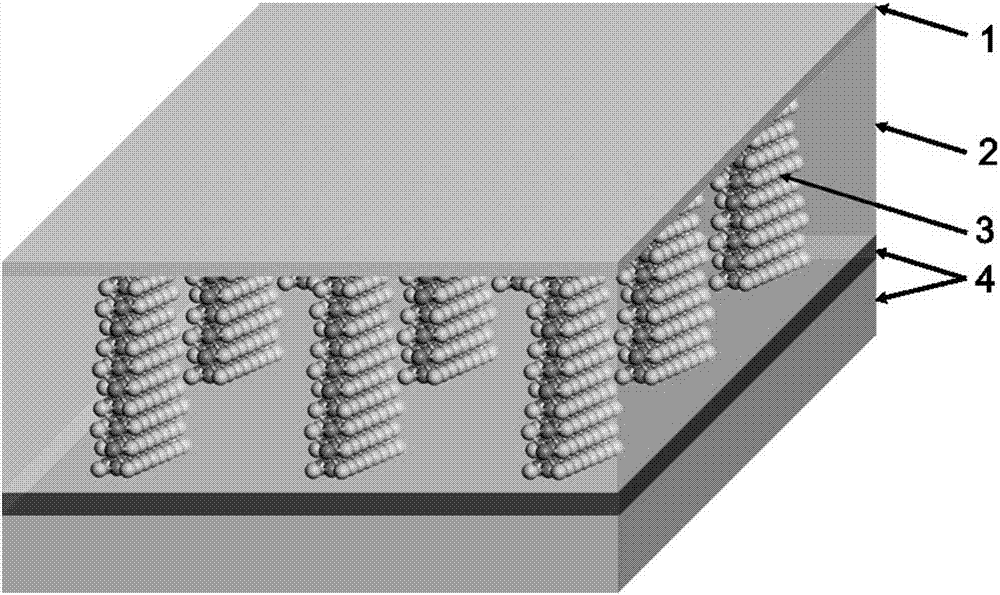

[0036] Such as figure 1 Shown, this specific embodiment adopts following technical scheme: it comprises gold electrode 1, PMMA insulation layer 2, vertical tin disulfide nanosheet 3 and conductive substrate FTO glass 4; figure 1 The middle gold electrode is the positive electrode, the FTO glass 4 is the negative electrode, the vertical tin disulfide nanosheet 3 is the photoelectric conversion core unit, and the PMMA insulating layer 2 covers the middle tin disulfide nanosheet, and isolates the upper and lower electrodes to prevent short circuit.

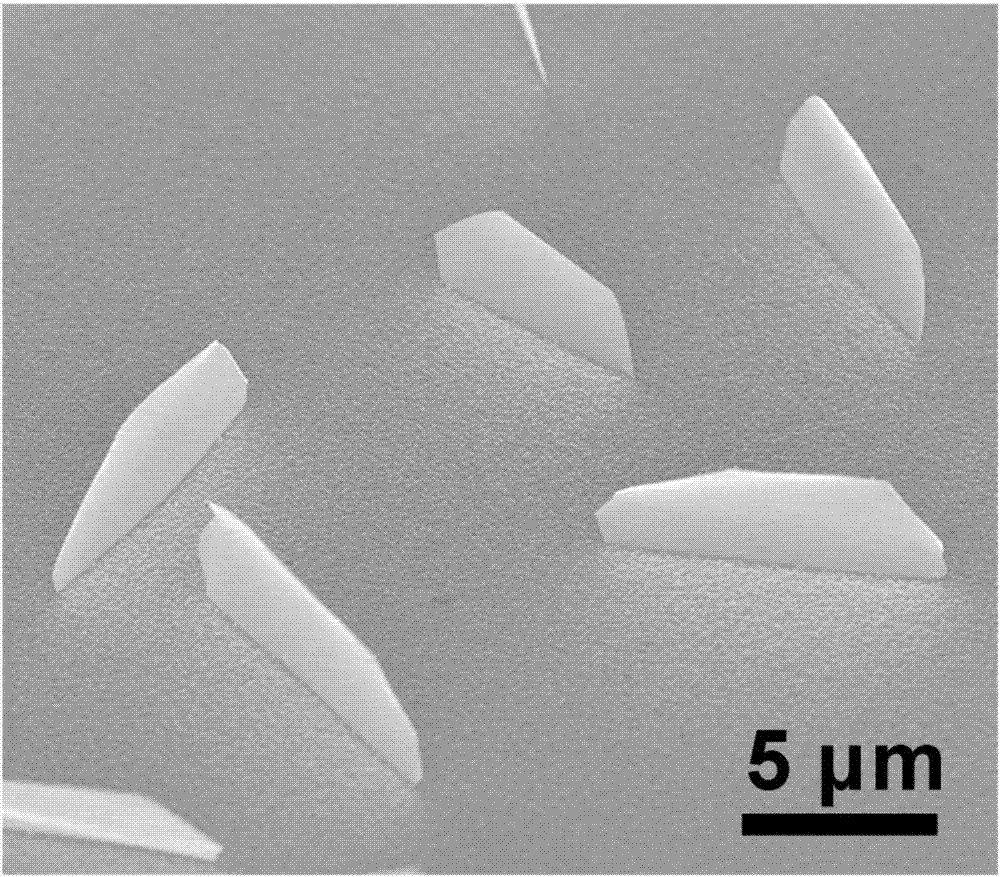

[0037] Such as figure 2 As shown, using the chemical vapor deposition process, when the growth temperature is ~450 ° C and the growth time is 5 min, free-standing vertical tin disulfide nanosheets can be grown on the FTO substrate.

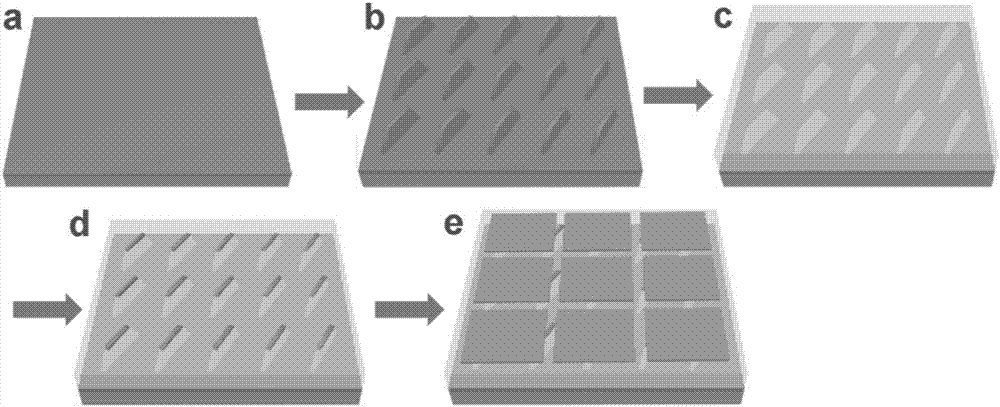

[0038] Such as image 3 As shown, the grown FTO substrate ( image 3 b) Spin-coat a layer of PMMA on the top to completely coat the vertical tin disulfide nanosheets, wherein the spin-coating paramet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com