Translation swallow-shaped cam core shaft type smart three-claw automatic centering fixture

An automatic centering, camshaft technology, applied in the direction of clamping, positioning device, clamping device, etc., to achieve the effect of compact shape structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

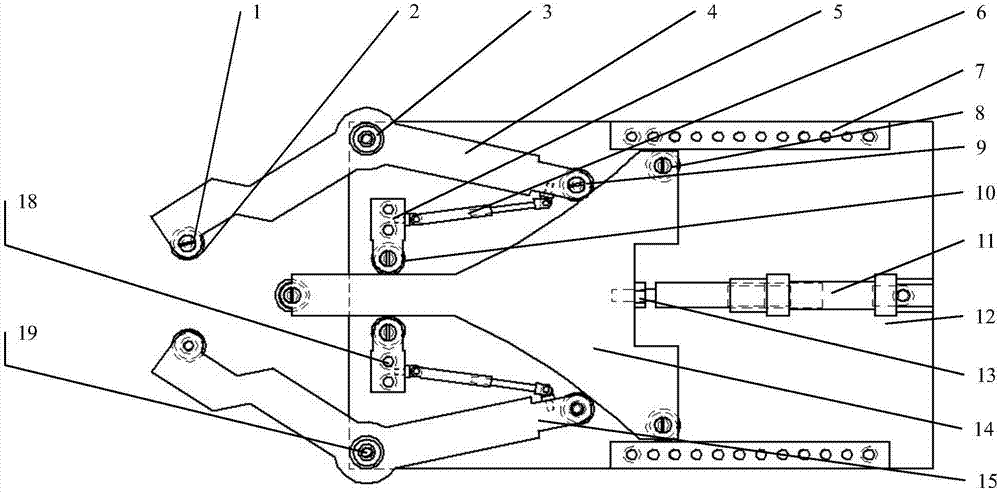

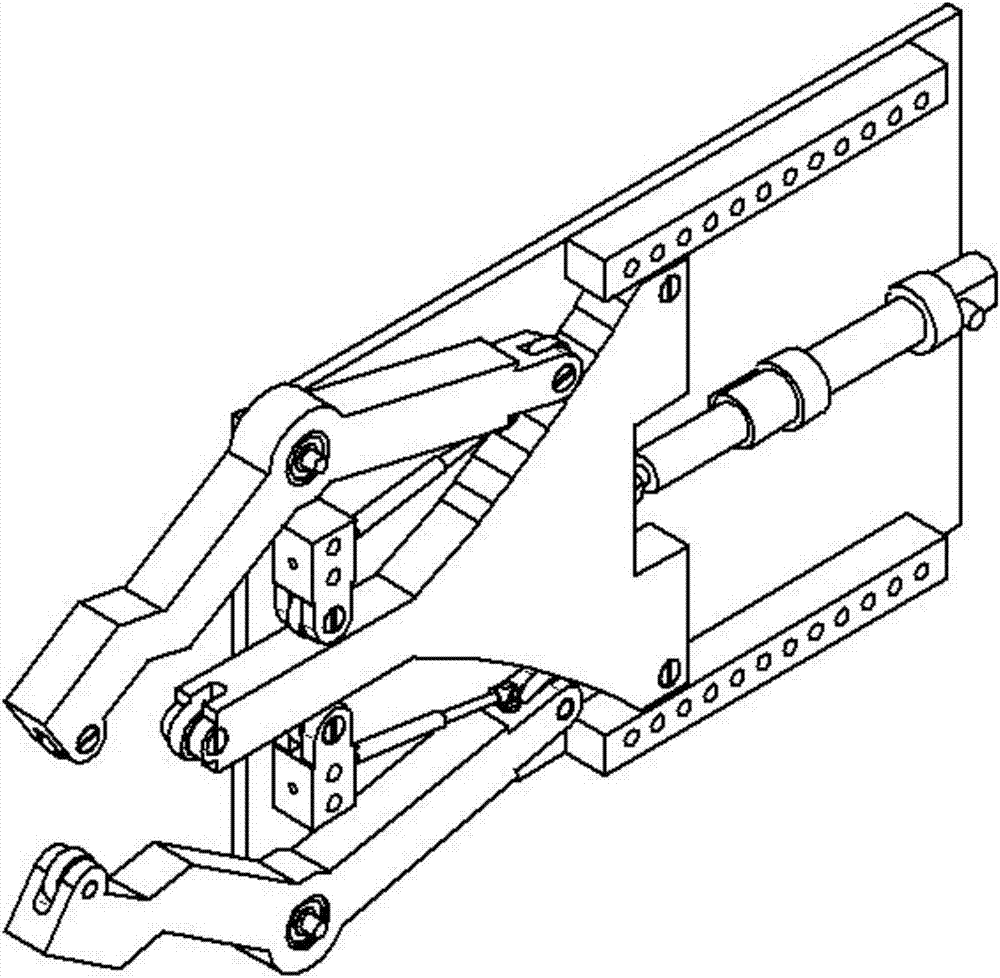

[0019] in accordance with Figure 1.1-1.2 As shown in the assembly projection diagram of the translational Stefanie cam mandrel type smart three-jaw self-centering fixture, the lever (4), bearing fixing screw (1), jaw bearing (2), support bearing (9), pull The spring hanging twist (15) is installed in place to form a lever assembly. Install the Stefanie camshaft (14), bearing fixing screw (1), jaw bearing (2) and rear guide bearing (8) in place in turn to form the Stefanie camshaft assembly. Install the front guide block (5), the front guide bearing (10), the bearing fixing screw (1), and the tension spring hanger (15) in place in turn to form the front support assembly. Finally, the lever assembly, front support assembly, Stefanie cam assembly, front box plate (17), lever slewing bearing (3), lever fastening screw (19), guide fastening screw (18), guide rail (7) , tension spring (6), drive cylinder (11), cylinder positioning pin (12), lock nut (13), rear box plate (16) are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com